Specially-shaped blind hole rotating cathode electrolytic machining device

A technology of rotating cathode and processing device, which is applied to electric processing equipment, electrochemical processing equipment, auxiliary devices, etc., can solve the problems of uneven flow field and bosses at the bottom of blind holes, and achieve uniform flow field, good quality, The effect of improving the efficiency of electrolytic machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the drawings.

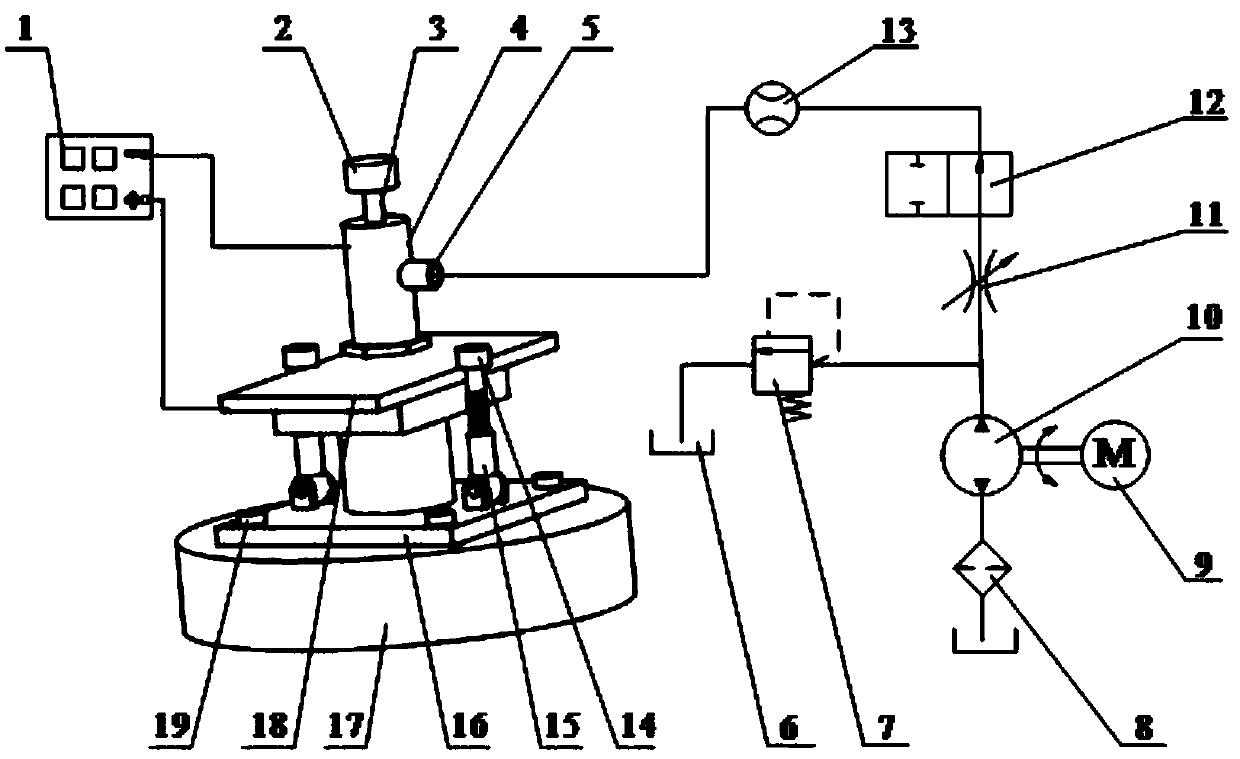

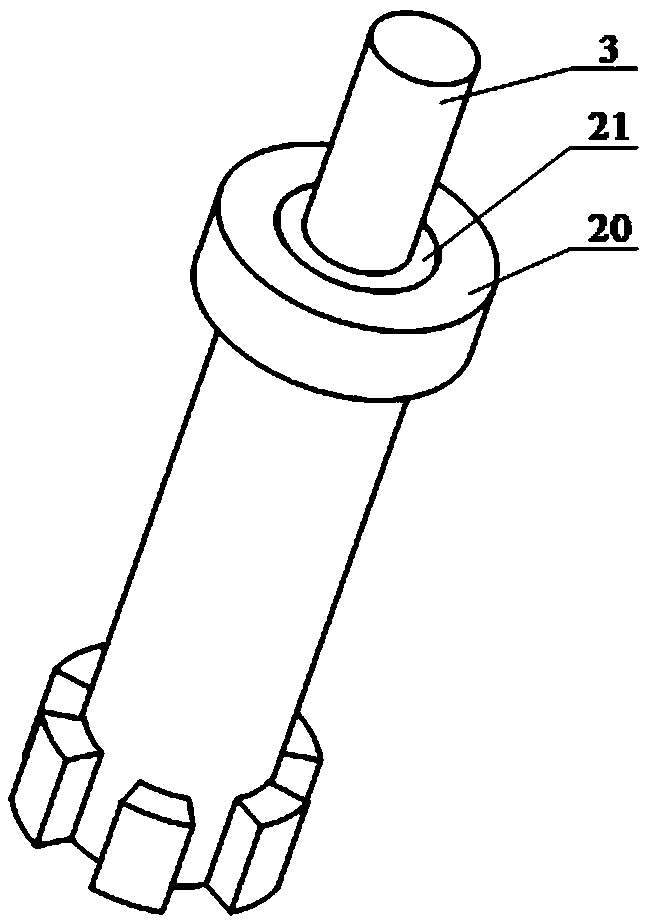

[0018] The structure of the electrochemical machining method and device of a special-shaped blind hole rotating cathode of the present invention is as follows figure 1 As shown, it includes a tool cathode device, an electrolytic tooling device, a workpiece and a machine tool system, and an electrolyte circulation system. A rotatable rotor 3 is provided on it. The rotor 3 is controlled by the machine tool spindle to rotate and stir the electrolyte to make the flow field Evenly, a series of machining is realized by the movement of the workpiece on the tooling, and the electrochemical machining of the special-shaped blind hole is completed by the spindle feed. The electrolyte circulation system is formed by the liquid inlet pipe 5 connected with the cathode device of the tool through the flow meter 13, the reversing valve 12, the throttle valve 11, the two-way variable valve 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com