Electrolytic machining process method of open type blisk

A technology of integral blisk and processing technology, applied in the direction of electrochemical processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low efficiency of electrolytic processing, and achieve the effect of ensuring stability and continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0056] Process method of the present invention is specifically:

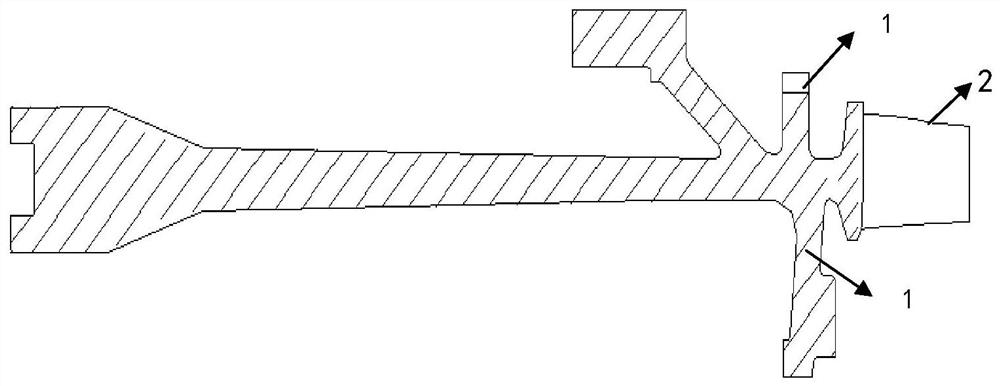

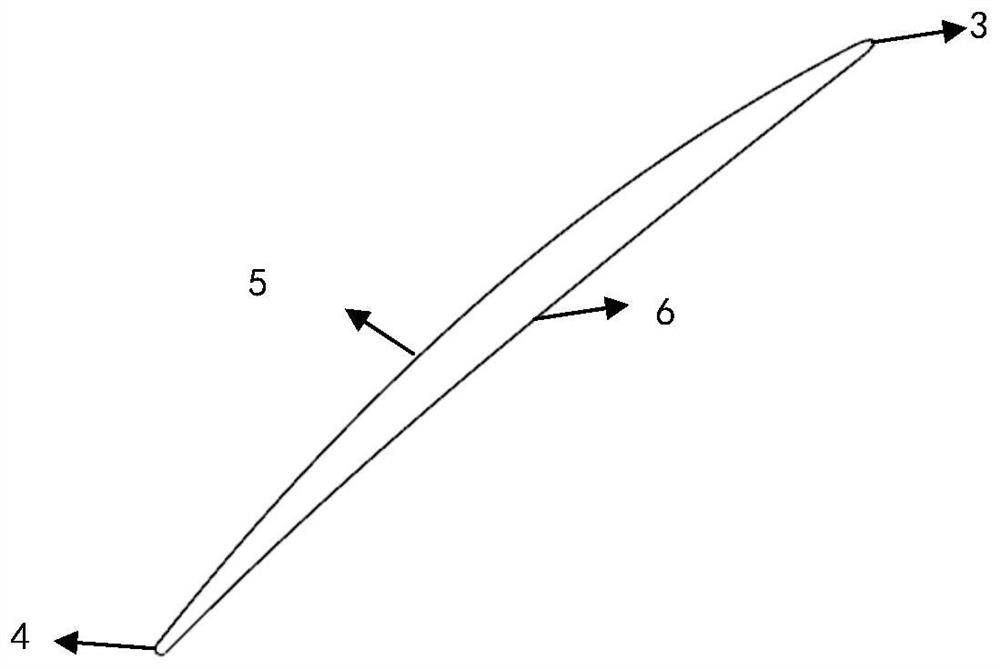

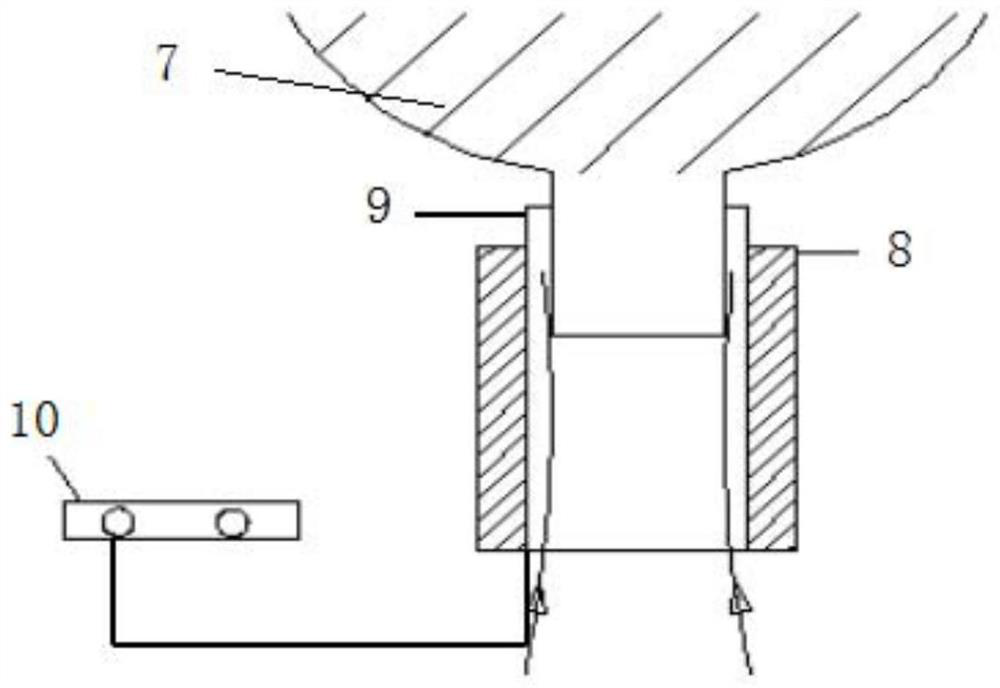

[0057] The schematic diagram of the open overall blisk structure is shown in figure 1 As shown, there are vanes 2 and flow channels 1 on it, and the structure of vanes 2 is as follows figure 2 Shown, one side of the blade is the exhaust side 3, the other half is the air intake side 4, one side is the blade pot 6, and the other side is the blade back 5. The open overall blisk is used as the workpiece anode 7, the processing tool is used as the tool cathode 8, the workpiece anode 7 is connected to the positive pole of the power supply, and the tool cathode 8 is connected to the negative pole of the power supply to perform electrolytic machining. The processing technology is optimized and improved from the following aspects:

[0058] (1) Improvement in design of power overload protection parameters. In electrolytic machining, the overload protection of the power supply mainly refers to a pre-detection of the ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com