A Method for Electrolytic Machining of Non-uniform Double-rotating Integral Blisk Cascade Channels

A technology of cascade channels and integral blisks, which is applied in the direction of electrochemical processing equipment, metal processing equipment, manufacturing tools, etc., can solve difficult semi-finishing, inconsistent corrosion amount, large difference in margin of electrolytic forming cascade channels, etc. problem, to achieve the effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

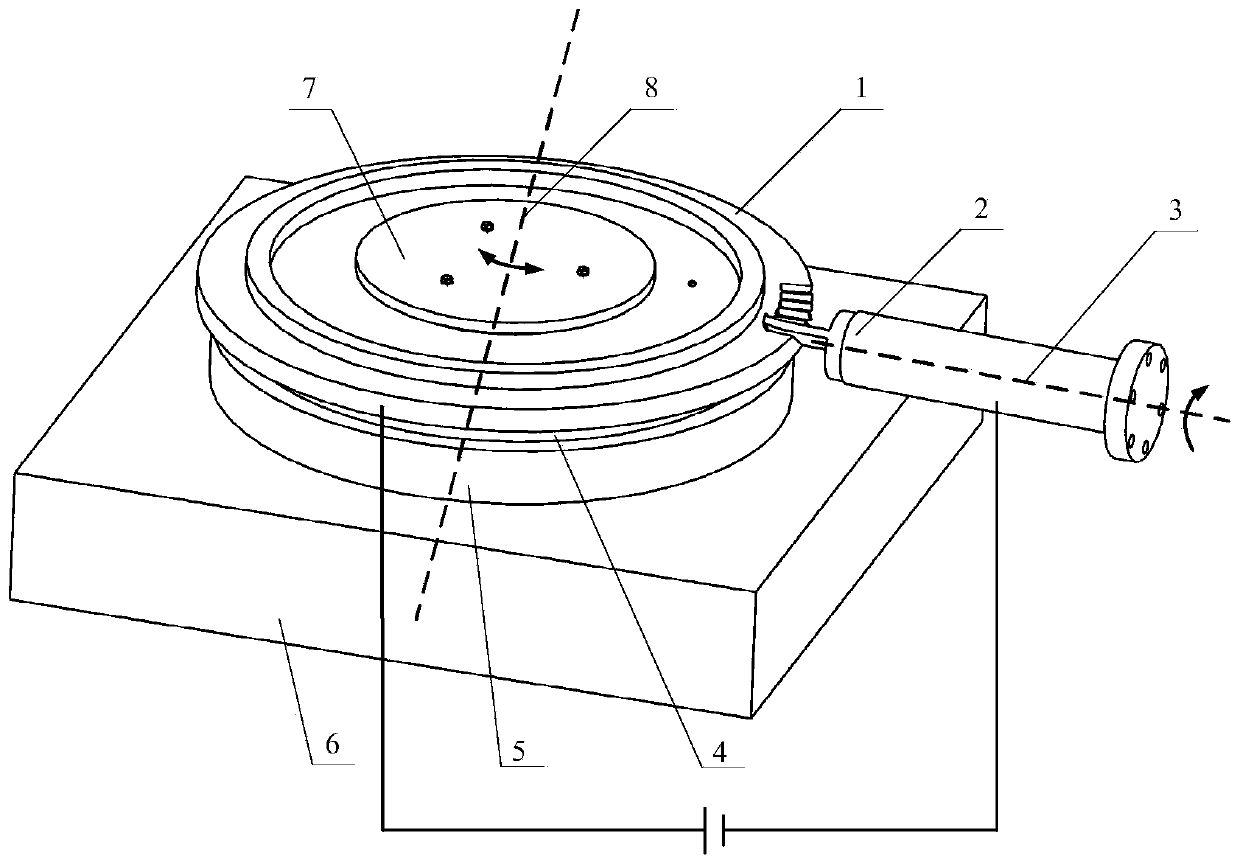

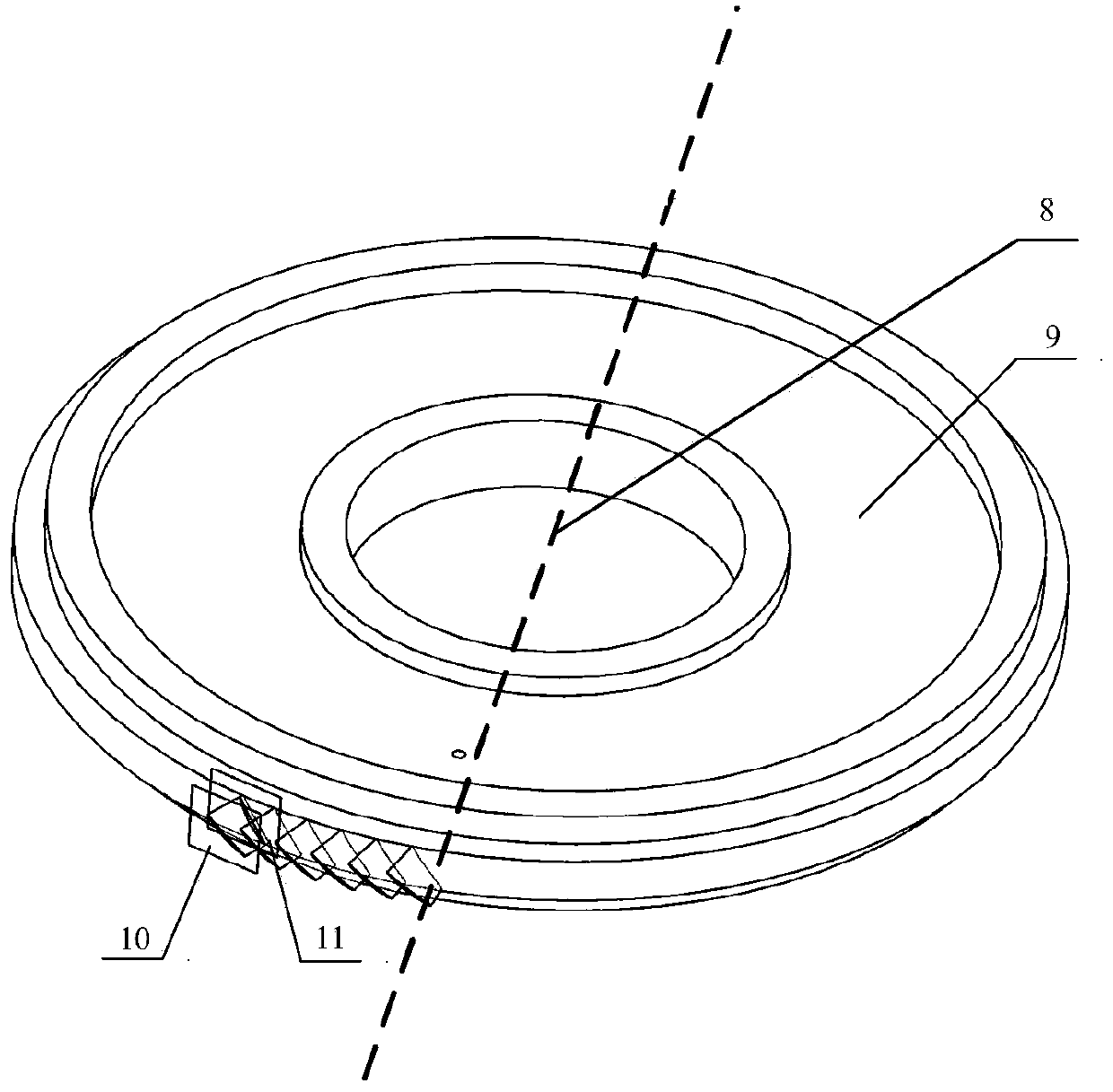

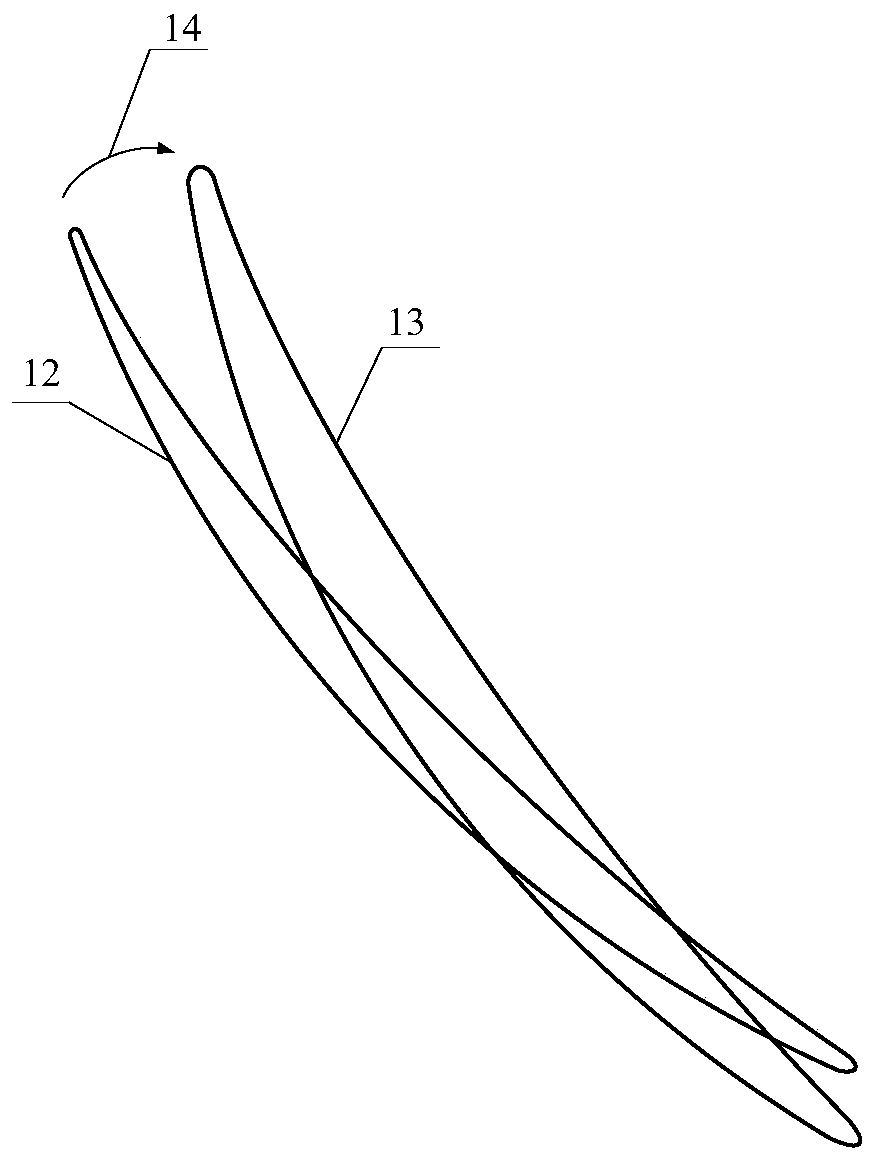

[0058] Such as figure 1 and as Figure 11 As shown, the electrolytic machining device of the present invention includes a whole plate blank 1, a tool cathode 2, a fixture disc 4, a turntable 5, a working platform 6, a pressing plate 7, an electrolytic machining fixture 36, a large gear 37, a pinion 38 and a motor 39. The whole plate blank 1 is connected with the fixture plate 4 by pins, the fixture plate 4 is connected with the turntable 5 by screws, the turntable 5 is located on the working platform 6, the pressure plate 7 is connected with the fixture plate 4 by screws, and the whole plate blank 1 is fastened. Among them, the pressure plate 7, the entire plate blank 1, the fixture plate 4, and the turntable 5 are arranged coaxially. Driven by the turntable 5, the pressure plate 7, the entire plate blank 1 and the fixture plate 4 rotate toge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com