Offline positioning and reference correcting device for blade with journal

A technology of blades and shafts, which is applied in the field of datum correction devices, can solve problems such as high labor intensity, unstable quality, and surface differences, and achieve the effects of avoiding processing time, improving processing consistency, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, specific implementations of the present invention are now described.

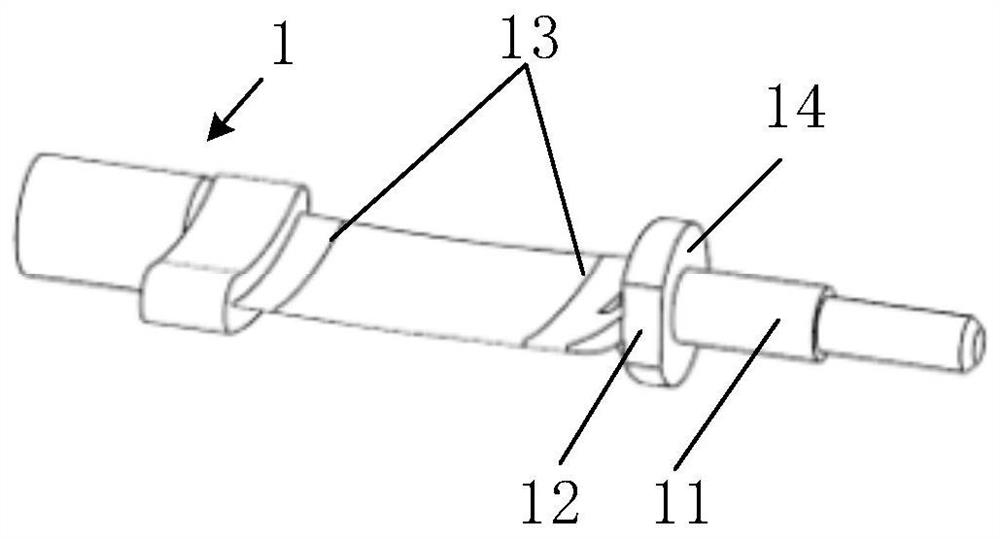

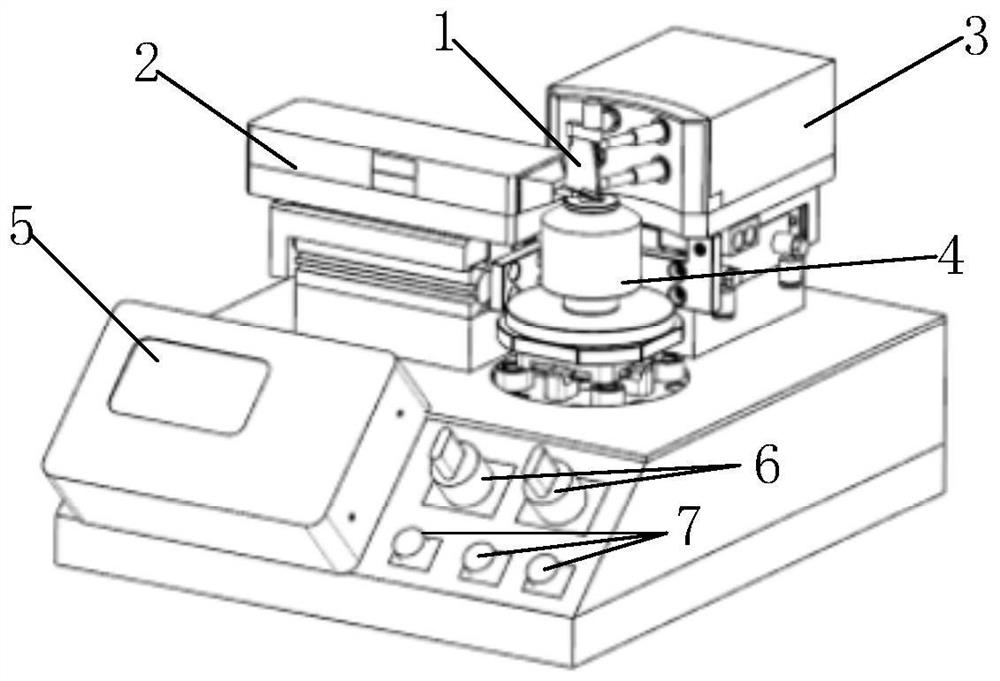

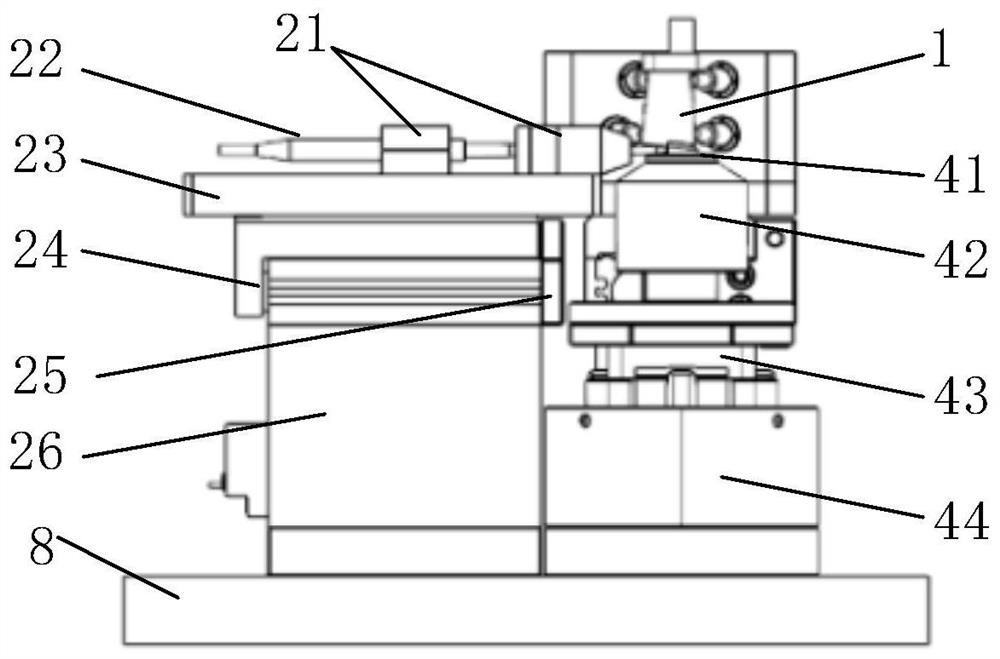

[0020] figure 1 It is a schematic diagram of the three-dimensional structure principle of a blade with a journal; figure 2 It is a schematic diagram of the three-dimensional structure principle of the off-line positioning and reference correction device for blades with journals according to a specific embodiment of the present invention; image 3 for figure 2 Schematic diagram of the principle of the orthographic structure; Figure 4 for image 3 Schematic diagram of the side view structure. see Figure 1-Figure 4 As shown, the present invention provides an off-line positioning and reference correction device for blades with journals, which is used for positioning and correcting blades with journals 1 that have completed batch milling. The blades with journals 1 Including blade j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com