Blisk five-axis channel combined milling method

A kind of blisk and milling processing technology, which is applied in the direction of metal processing equipment, manufacturing tools, milling machine equipment, etc., can solve the problems of machining accuracy, easy deformation, complex structure, etc. The effect of efficiency, uniform distribution of margin, and huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

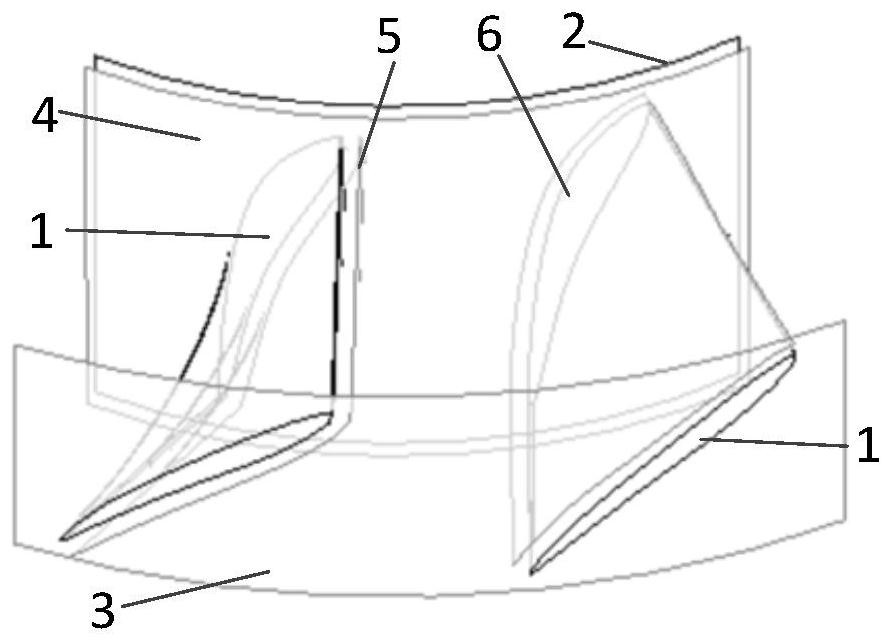

[0027] Example 1: as Figure 1-5 As shown, a method for compound milling of an integral blisk five-axis channel includes the following steps:

[0028] 1) as figure 1 The division of the to-be-processed area of the blisk channel as shown in Fig. 1 is to establish a five-axis machining area of the blisk channel. The area enclosed by the offset surface 5, the offset surface 4 of the inner hub surface 2 of the integral blisk, and the blade tip turning surface 3, wherein the offset distance of the offset surface is the machining allowance;

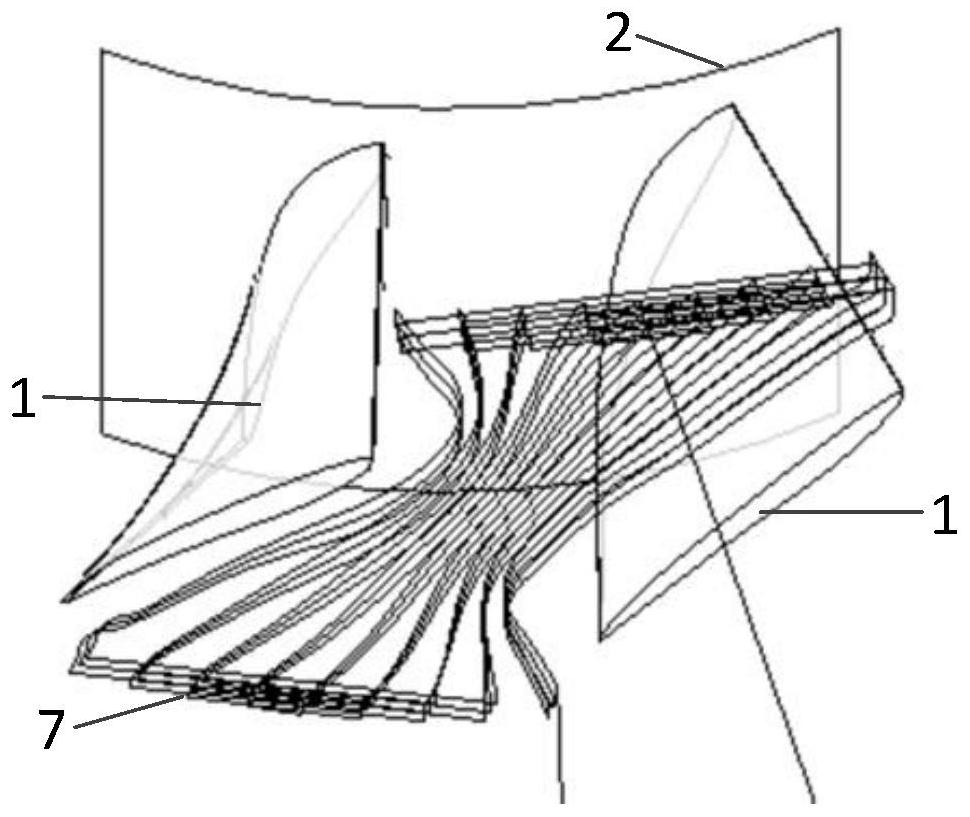

[0029] 2) Planning of the rough machining tool path of the blisk channel: the first 10-15% of the overall blisk channel in the depth direction from the blade tip turning surface 3 to the inner hub surface offset surface 4 is the first section In the rough milling and slotting milling interval, the milling toolpath is the first roughing toolpath trajectory 7; the latter 85-90% of the depth direction of the blisk channel is the second rough...

Embodiment 2

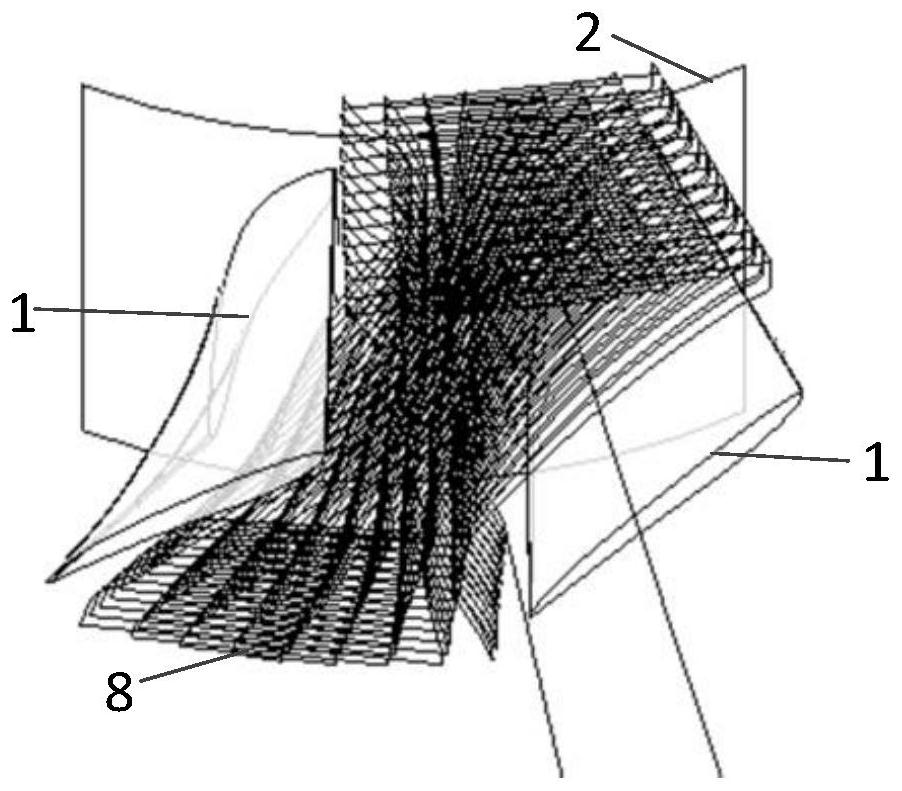

[0036] Embodiment 2 is identical with embodiment 1, and the difference is that it also includes step 5:

[0037] Step 5) Planning of the actual machining sequence of the blisk channel: take the first rough machining tool path 7 as the first machining program of the blisk, and execute it in all channels; The toolpath trajectory 8 is used as the second processing program of the blisk, and only the first channel of the blisk is executed; The second channel of the disc starts to execute, and the cycle goes to the last channel; the finishing toolpath path 9 is taken as the fourth machining program of the blisk, and the last remaining blade is machined separately. Using the tool path processing provided by the present invention, combined with the sequence provided in Embodiment 2, can improve the rigidity of the blade of the blisk during milling, and can make the machining accuracy of the blisk to meet the design requirements. A key technology in the milling process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com