Suction type electrolytic machining device and method for finishing internal structure

An internal structure and processing device technology, applied in electric processing equipment, electrochemical processing equipment, accessories, etc., can solve the problem of difficult to discharge the internal structure, difficult to discharge the internal structure of bubble electrolysis products, and hinder the electrochemical reaction between the surface of the internal structure and the electrode. and other issues to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

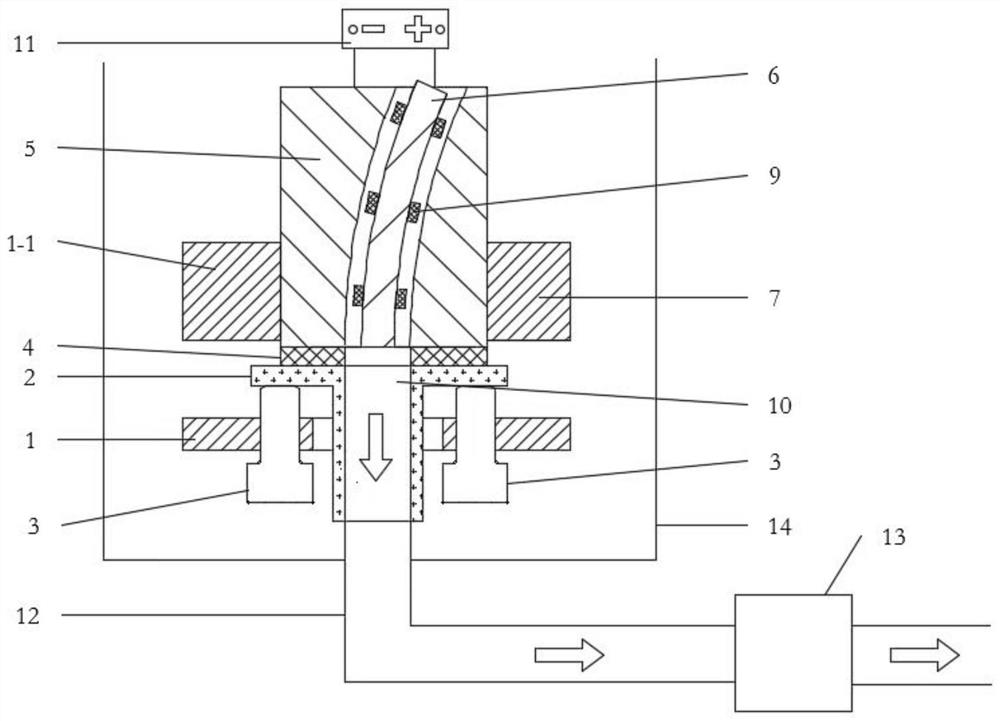

[0017] The present invention will be further described below in conjunction with accompanying drawing:

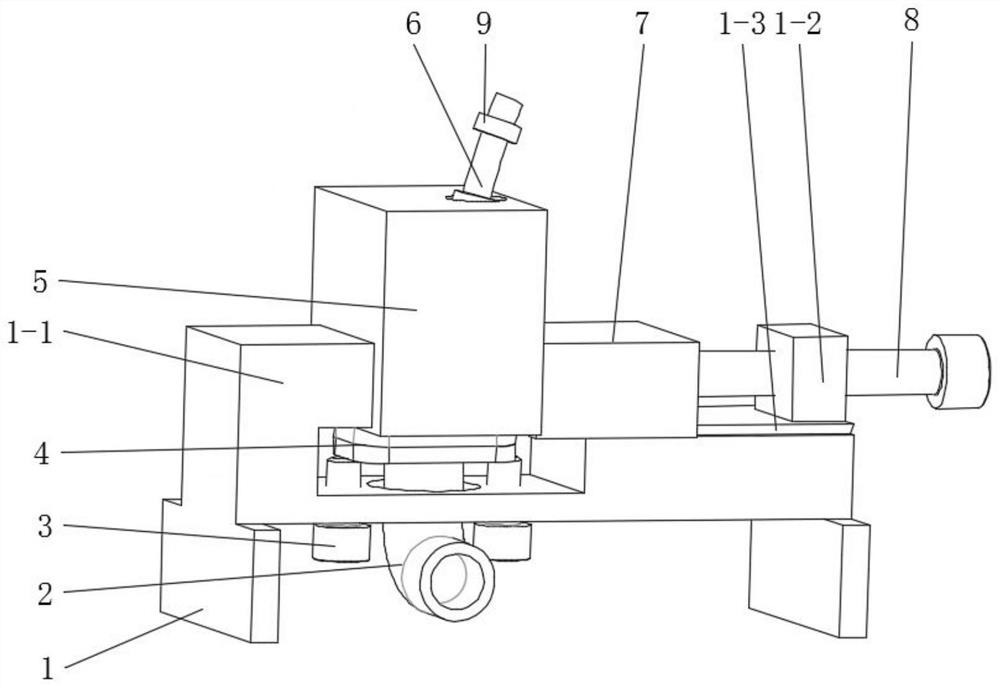

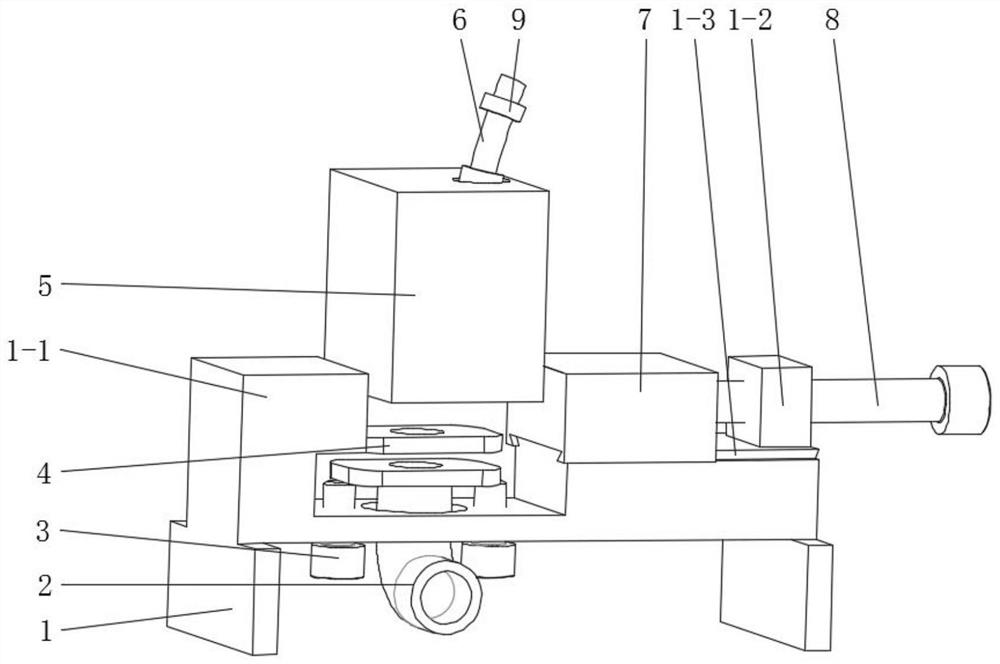

[0018] Such as figure 1 and 2 As shown, a suction electrolytic processing device for finishing the internal structure includes a holding device, a tool cathode 6, a suction pipe (2), a connecting pipe 12, a suction pump 13, and a power supply 11;

[0019] The above-mentioned clamping device includes a clamping frame 1, a slider 7, a bolt 8, a compression screw 3 and a gasket 4; wherein the clamping frame 1 includes a base, and the left and right ends of the base are respectively provided with a left top block 1-1 and a The right top block 1-2, the right part of the clamping frame 1 is also provided with a horizontal chute 1-3, the above-mentioned slider 7 is installed on the horizontal chute 1-3; the workpiece anode 5 is installed on the left top block 1-1 and the slide between the block 7; the above-mentioned tight gasket 4 is located between the workpiece anode 5 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com