Method for preparing calcium sulfate dihydrate whisker from mirabilite and calcium water

A technology of calcium sulfate dihydrate and Glauber's salt, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the problems of Glauber's salt containing many impurities, polluting fresh water resources, and low utilization rate, and achieve complete and uniform mass transfer , the effect of uniform reaction system and uniform morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

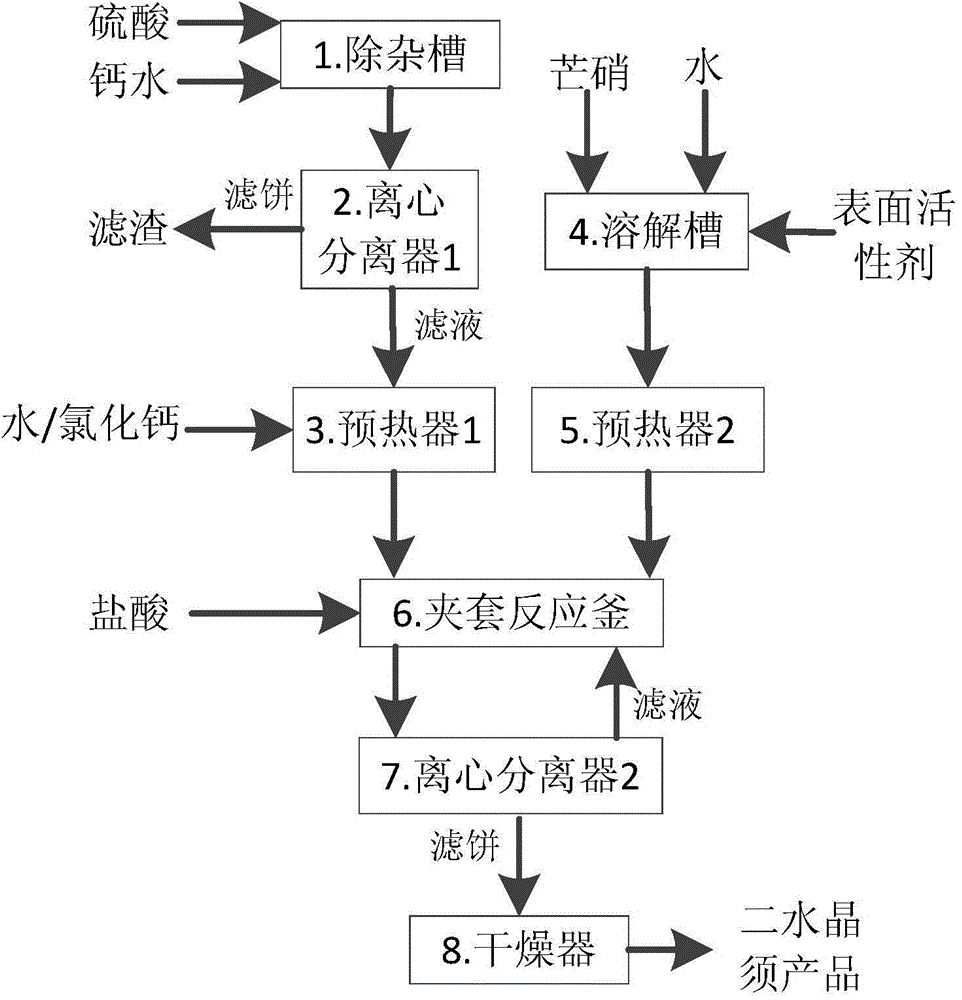

Method used

Image

Examples

Embodiment 1

[0032] The concrete steps of the method for preparing calcium sulfate dihydrate crystal whisker with Glauber's salt and calcium water of the present invention are as follows:

[0033] (1) Purification of calcium aqueous solution:

[0034] Add it to industrial calcium water under normal temperature conditions (the amount is to remove impurities (Ba 2+ 、Sr 2+ ) 1.05 times of required amount) concentration is 10~30wt% sulfuric acid, stirs 20min, centrifuges solid-liquid then, obtains relatively pure calcium aqueous solution;

[0035] (2) Preparation of raw material solution:

[0036] Add calcium chloride or water to the calcium water to adjust the concentration of calcium water to 0.6mol / L;

[0037] Prepare an aqueous solution of Glauber's salt with a concentration of 1.6mol / L, the volume ratio of the Glauber's salt solution to the calcium aqueous solution is 0.4:1, and add 0.5wt% surfactant to the prepared Glauber's salt solution;

[0038] Then preheat the calcium water and ...

Embodiment 2

[0047] The concrete steps of the method for preparing calcium sulfate dihydrate crystal whisker with Glauber's salt and calcium water of the present invention are as follows:

[0048] (1) Purification of calcium aqueous solution:

[0049] Adding sulfuric acid with a concentration of 10-30wt% to industrial calcium water under normal temperature conditions, the amount of addition is Ba 2+ 、Sr 2+1.10 times the required amount, stirred for 50 minutes, and then centrifuged to separate the solid and liquid to obtain a relatively pure calcium aqueous solution;

[0050] (2) Preparation of raw material solution:

[0051] Add calcium chloride or water to the calcium water to adjust the concentration of calcium water to 1.6mol / L;

[0052] Prepare an aqueous solution of Glauber's salt with a concentration of 0.6 mol / L, the volume ratio of the Glauber's salt solution to the calcium aqueous solution is 1.2:1, and add 1wt% surfactant to the prepared Glauber's salt solution;

[0053] Then...

Embodiment 3

[0062] The concrete steps of the method for preparing calcium sulfate dihydrate crystal whisker with Glauber's salt and calcium water of the present invention are as follows:

[0063] (1) Purification of calcium aqueous solution:

[0064] Adding sulfuric acid with a concentration of 10-30wt% to industrial calcium water under normal temperature conditions, the amount of addition is Ba 2+ 、Sr 2+ 1.08 times the required amount, stirred for 30 minutes, and then centrifuged to separate the solid and liquid to obtain a relatively pure calcium aqueous solution;

[0065] (2) Preparation of raw material solution:

[0066] Add calcium chloride or water to the calcium water to adjust the concentration of calcium water to 1.0mol / L;

[0067] Prepare an aqueous solution of Glauber's salt with a concentration of 1.0mol / L, the volume ratio of Glauber's salt solution to calcium aqueous solution is 0.8:1, and add 0.8wt% surfactant to the prepared Glauber's salt solution;

[0068] Then prehe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com