Patents

Literature

38results about How to "Reduce shaft power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

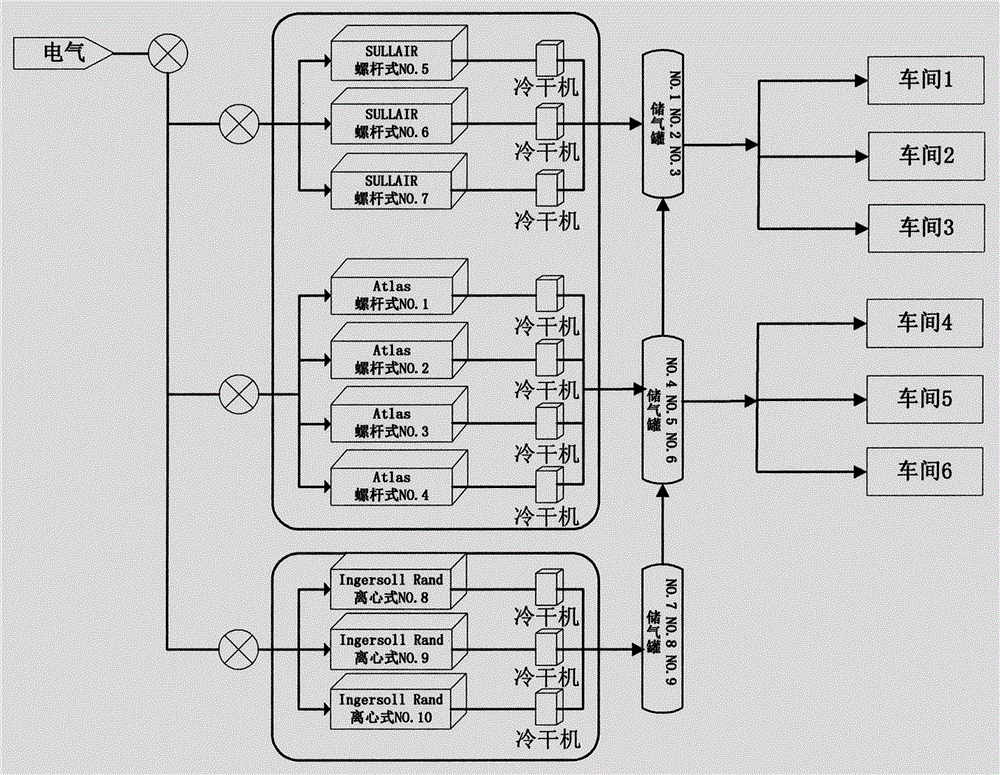

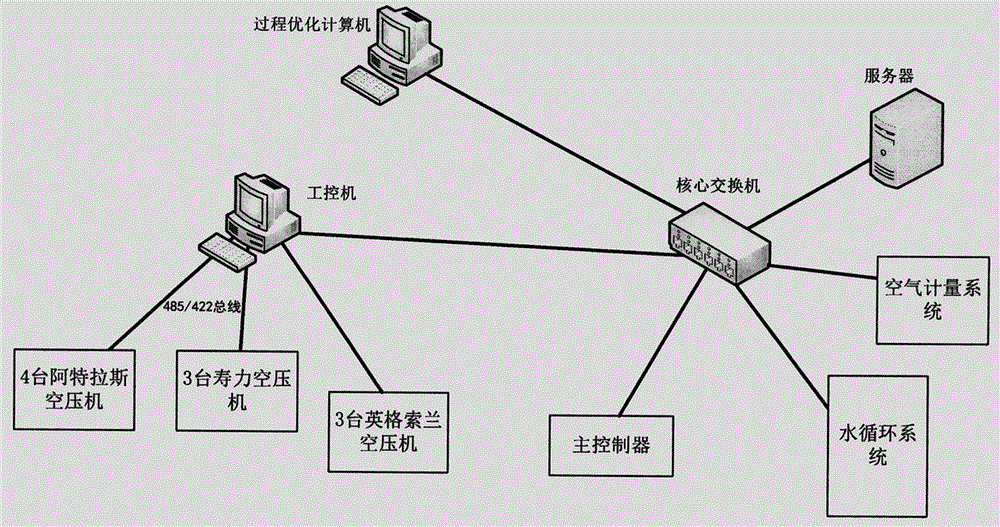

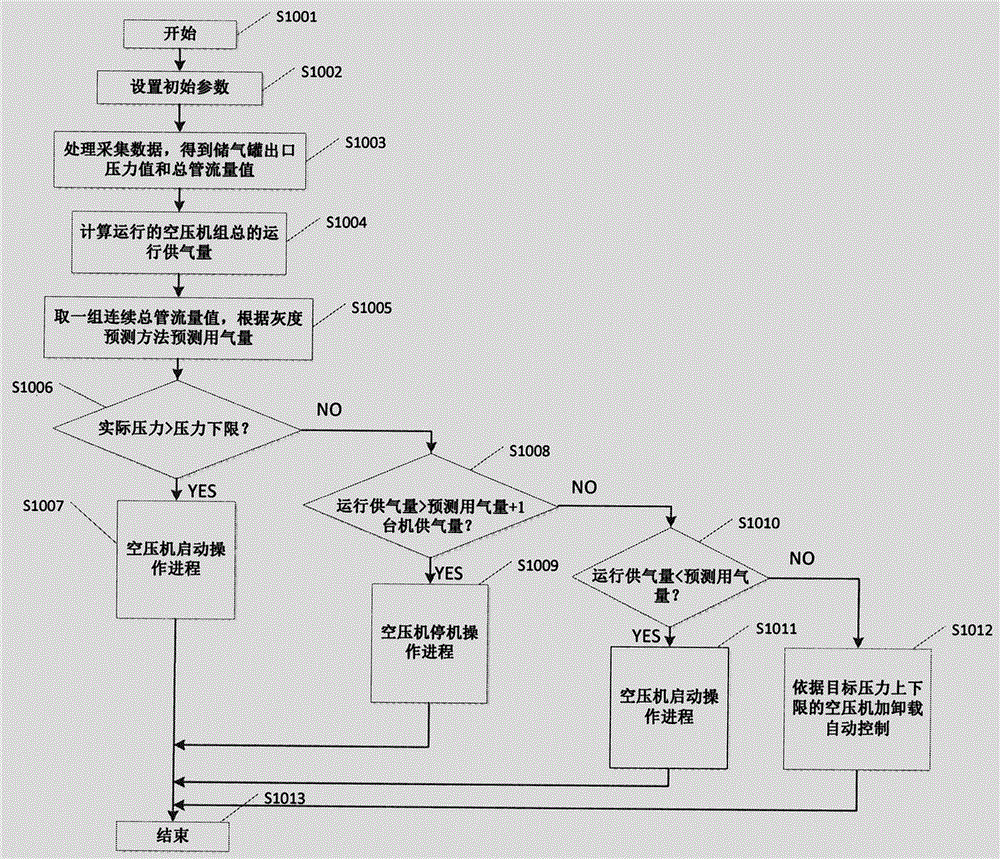

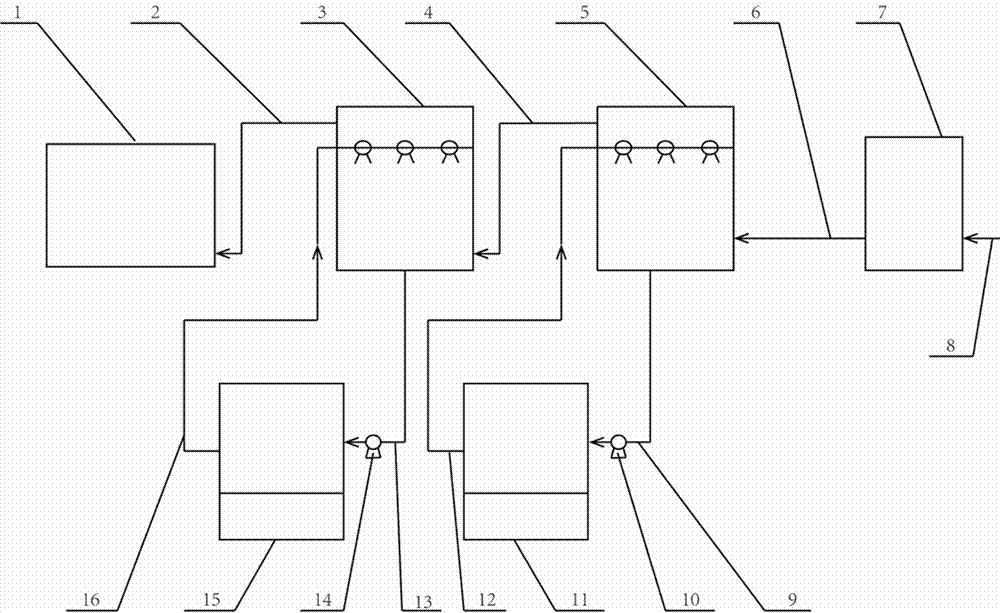

Energy-saving control method for compressed air industrial screw-type air compressor group control system

ActiveCN105156327AAvoid frequent start and stopReduce shaft powerMachines/enginesFrequency changerAutomatic control

The invention discloses an energy-saving control method for a compressed air industrial screw-type air compressor group control system. The method comprises automatic control of the number of air compressors and automatic loading and uploading control of screw-type air compressors. In the system, gray scale prediction of total run traffic is conducted to control start and stop of the air compressors, so that the frequent start and stop defect of the air compressors is overcome, and the system operation stability is greatly improved; meanwhile, automatic loading and uploading control of the screw-type air compressors is carried out, so that the system operating pressure is stable, the pressure fluctuation range is reduced, and a defect that the power consumption of a frequency converter is increased caused by modification of frequency conversion control of an air compressor group. The method has the characteristics that the energy utilization efficiency is high, and the system is flexible in operation and stable in running.

Owner:深圳德尔科机电环保科技有限公司 +1

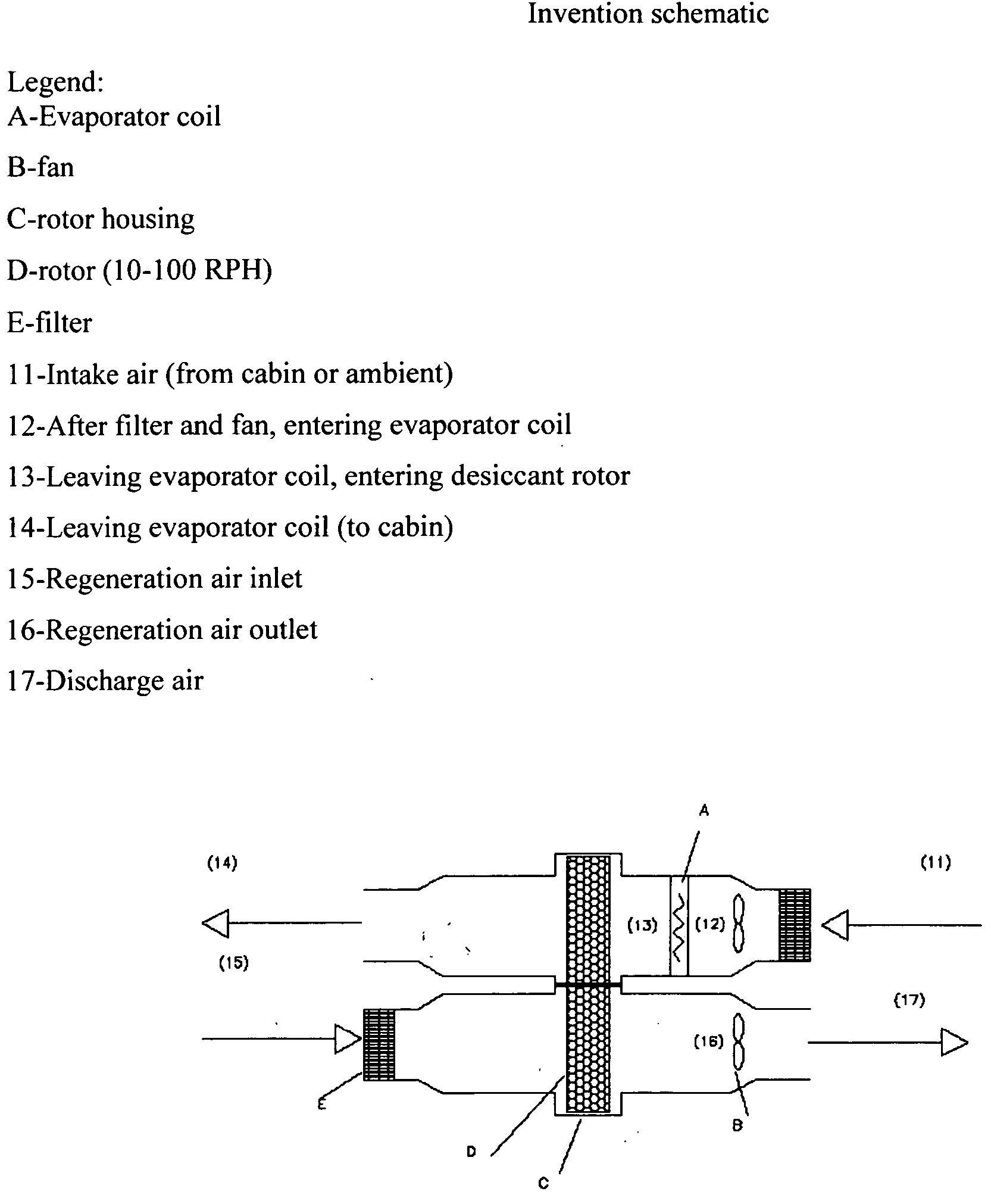

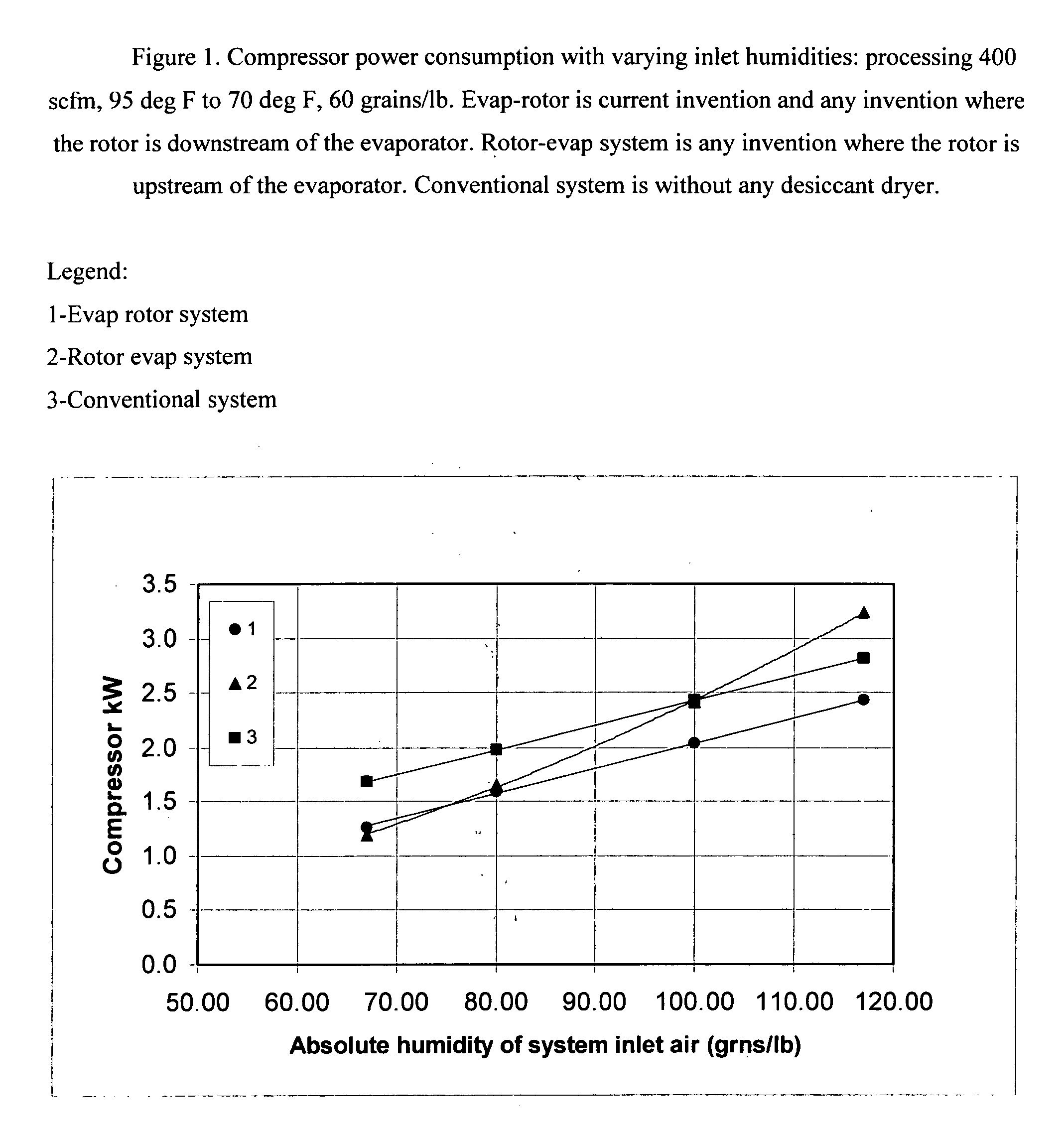

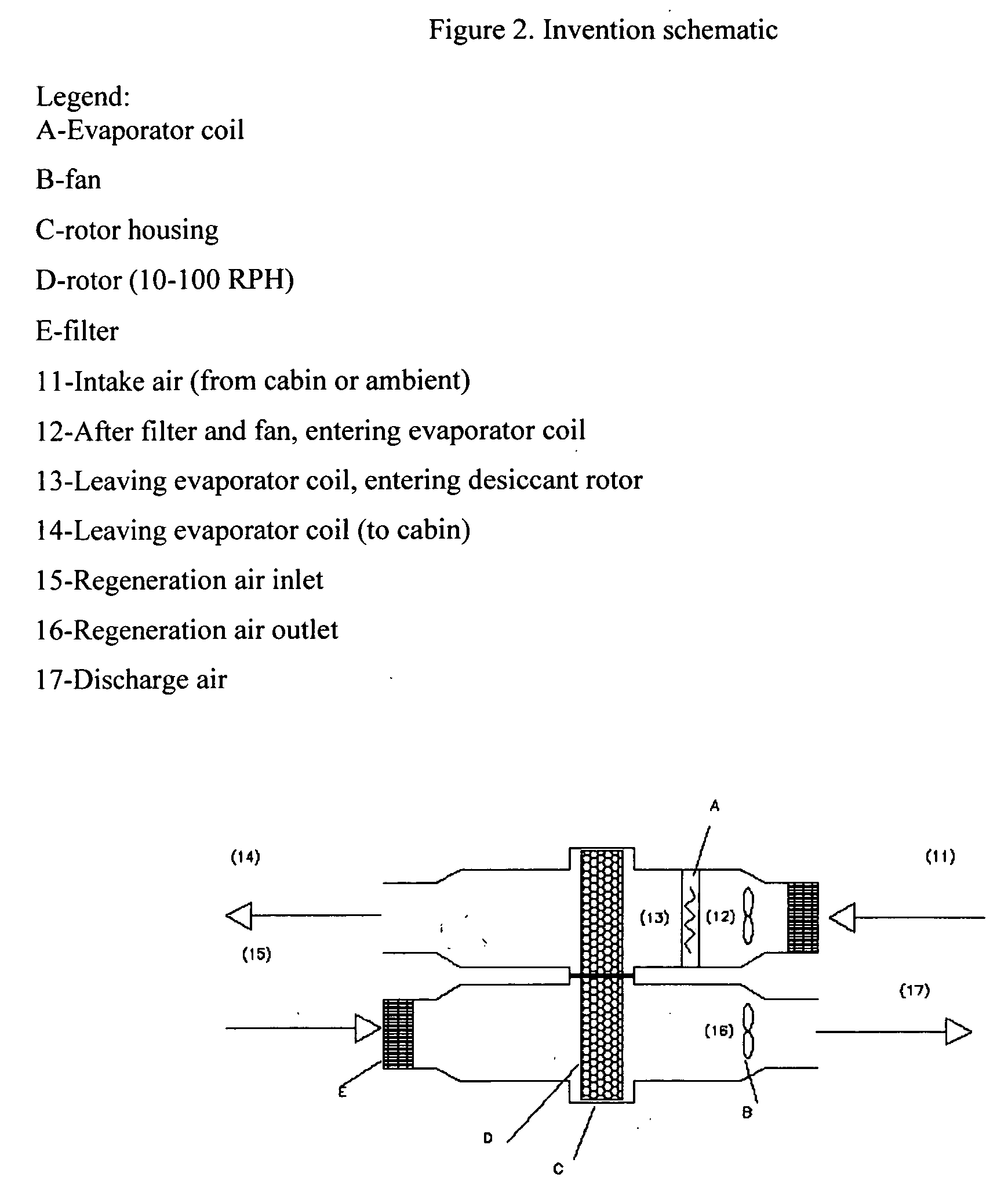

Rotor desiccant air-conditioning system for a motor vehicle

InactiveUS20050039481A1Improve comfortDefog capacityAir-treating devicesAir treatment detailsDesiccantEngineering

An air-conditioning system for a cabin of a motorized vehicle comprising of an evaporator and desiccant, where said desiccant is downstream of evaporator, and said desiccant is a rotor that uses nearby excess heat to regenerate the desiccant.

Owner:CHANT EILEEN

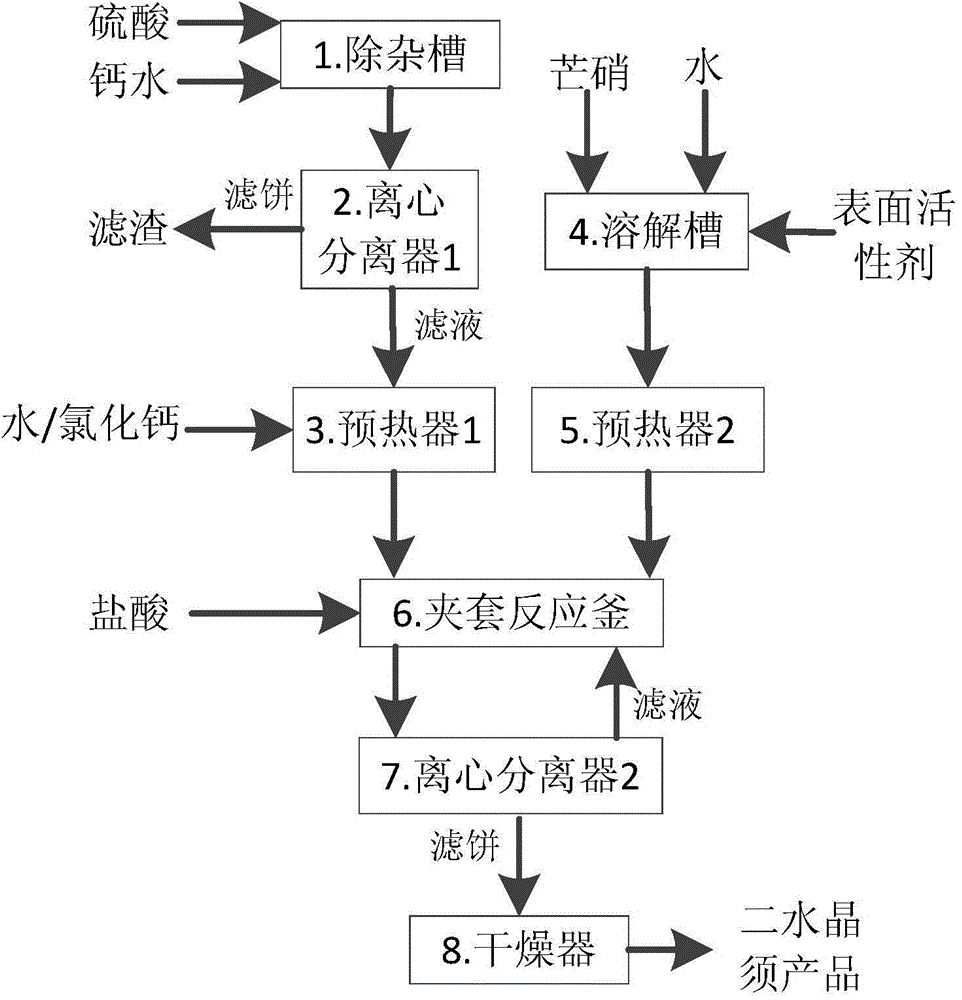

Method for preparing calcium sulfate dihydrate whisker from mirabilite and calcium water

ActiveCN104894650AUniform length and diameterUniform aspect ratioPolycrystalline material growthFrom normal temperature solutionsChemical industrySocial benefits

The invention discloses a method for preparing calcium sulfate dihydrate whisker from mirabilite and calcium water. The normal-pressure acidification process, which is utilized to produce the dihydrate gypsum whisker from industrial calcium water and mirabilite, can effectively utilize industrial wastewater (calcium water and mirabilite), solves the problem of discharge of the industrial wastewater, achieves the goal of green chemical industry, and completely conforms to the national industrial policy. The gypsum whisker belongs to a high-tech environment-friendly product, has the advantages of wide market demand prospects and obvious economic benefits, and has sufficient and cheap raw material resources in the local region after being put into production. The method is simple and easy to implement, and can easily implement industrialization. Therefore, the project can obtain huge economic benefit and social benefit if being researched and finally constructed in the local region. The finally obtained calcium sulfate dihydrate whisker has the advantages of uniform shape, proper length-diameter ratio (50 above), high yield (up to 84%) and high whiteness (at least 96%).

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

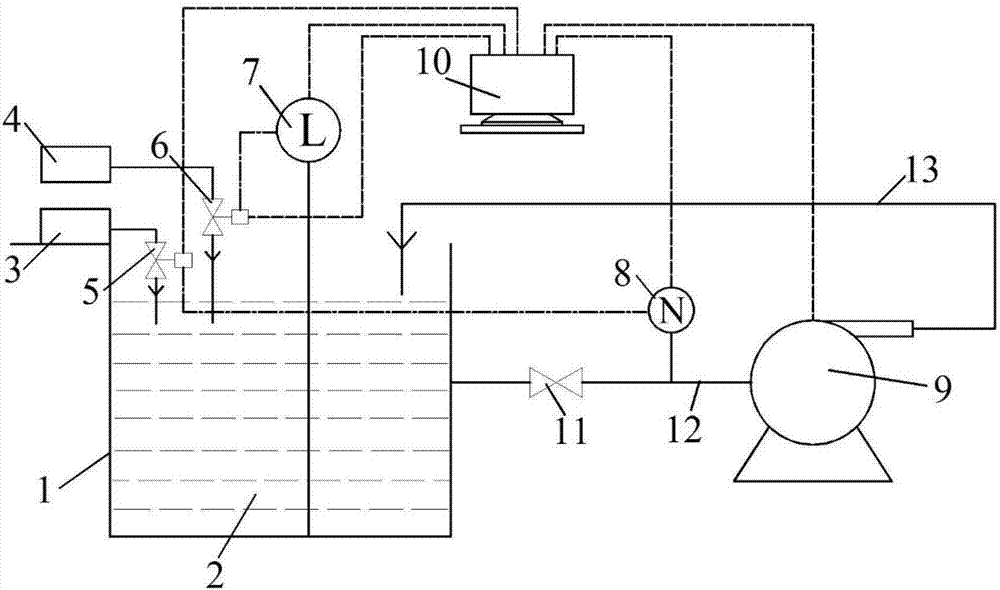

Method for improving efficiency of gas drainage liquid ring vacuum pump through macromolecular drag reduction agent

ActiveCN107152399ASuppressed vortexReduced eddy current lossPump componentsRotary piston pumpsEngineeringVacuum pump

The invention discloses a method for improving the efficiency of a gas drainage liquid ring vacuum pump through a macromolecular drag reduction agent, and belongs to methods for improving the efficiency of liquid ring vacuum pumps. The method comprises the steps that the quantitative macromolecular drag reduction agent is prepared and poured into a circulating pool continuously through a drag reduction agent filling machine till the optimal drag reduction concentration is reached; the gas drainage liquid ring vacuum pump is operated, and the macromolecular drag reduction agent serves as a working medium of the liquid ring vacuum pump to conduct gas drainage; and the viscosity and the liquid level of the drag reduction agent as well as the operation performance of the gas drainage liquid ring vacuum pump are monitored in real time, accordingly, the quantitative drag reduction agent is supplemented in the fixed time, and the drag reduction performance and the liquid level of the drag reduction agent are maintained. The macromolecular drag reduction agent is a polyacrylamide solution with the concentration being 0.1-0.5%. Through the method, the efficiency of the liquid ring vacuum pump can be substantially improved, operation energy consumption can be reduced, and the maintenance period and the service life of the liquid ring vacuum pump are obviously prolonged.

Owner:CHINA UNIV OF MINING & TECH

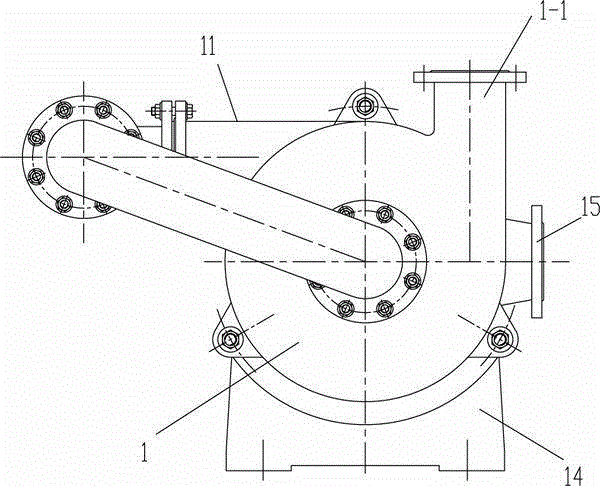

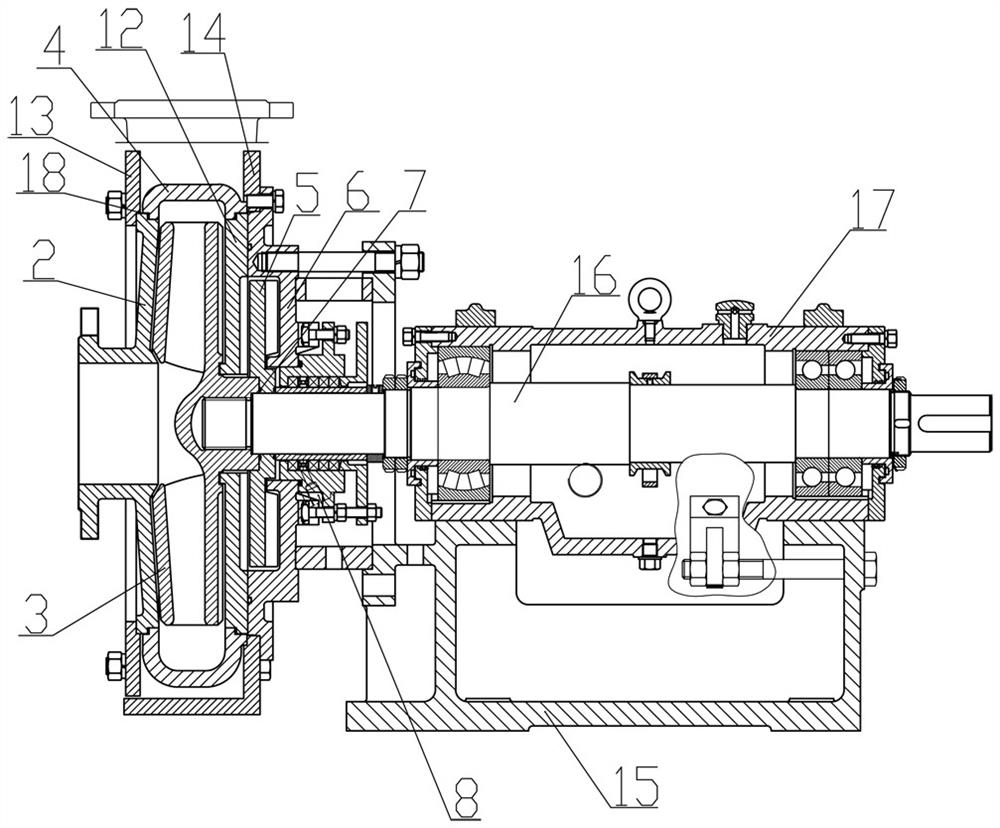

Slurry pump

ActiveCN102192184BComply with water conservancy characteristicsReduce resistancePump componentsPumpsImpellerEngineering

Owner:李国中

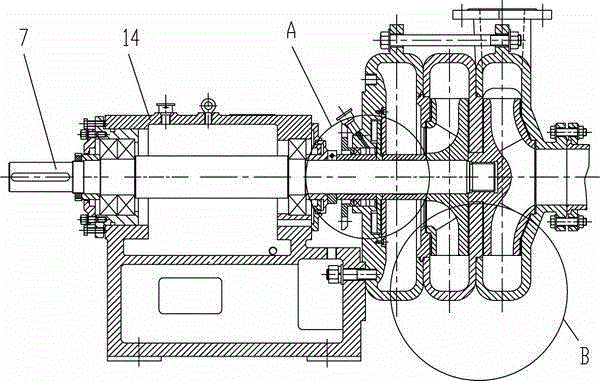

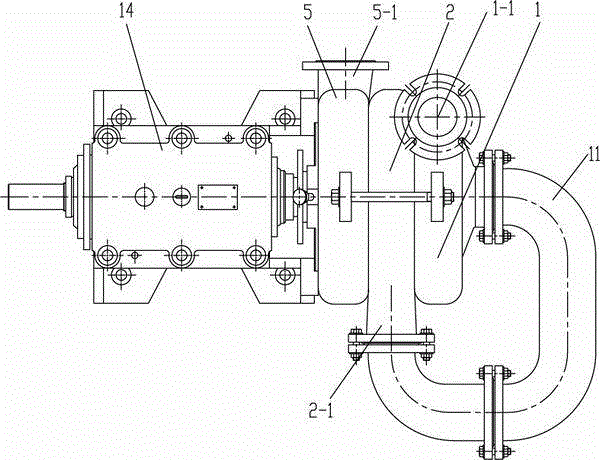

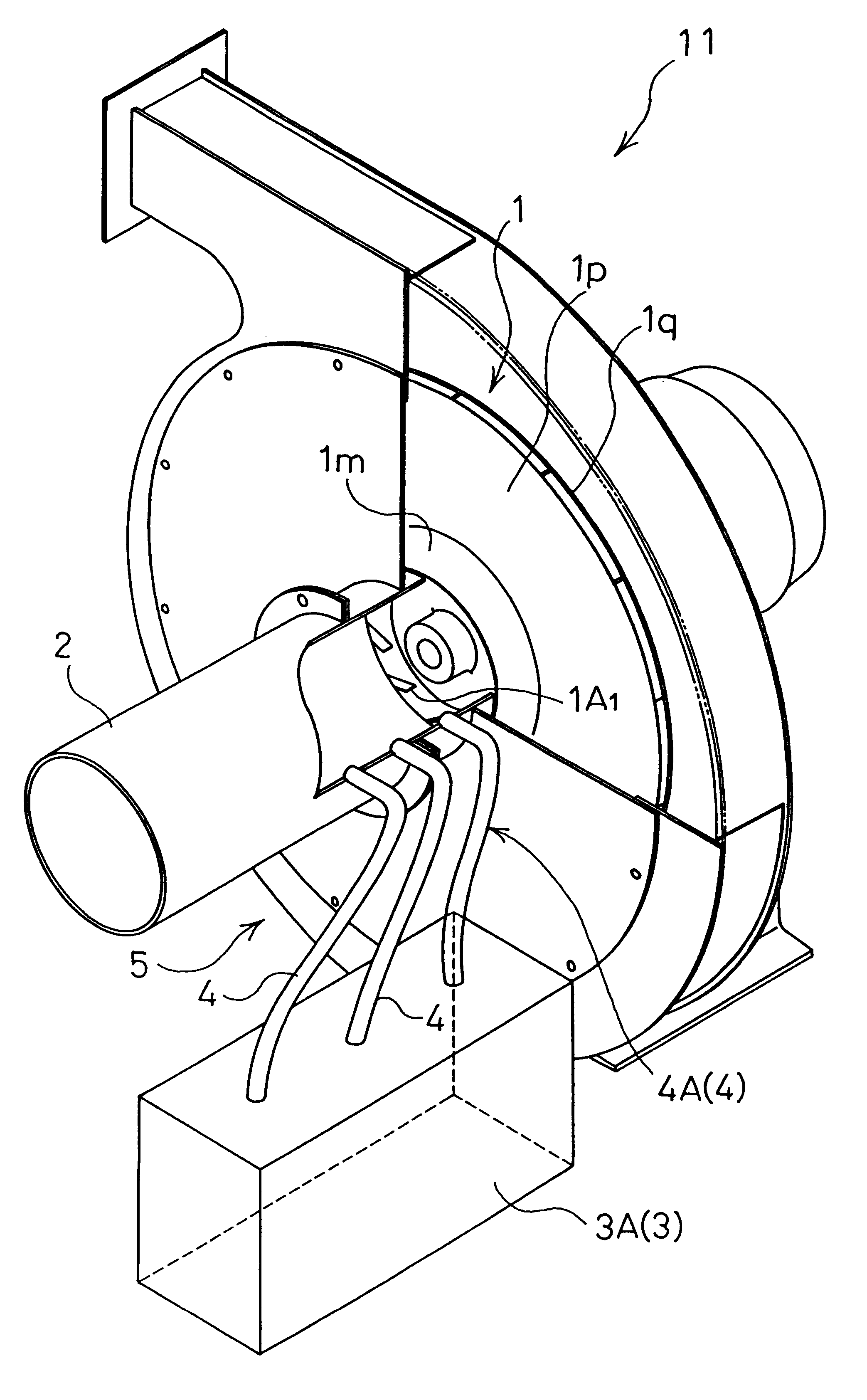

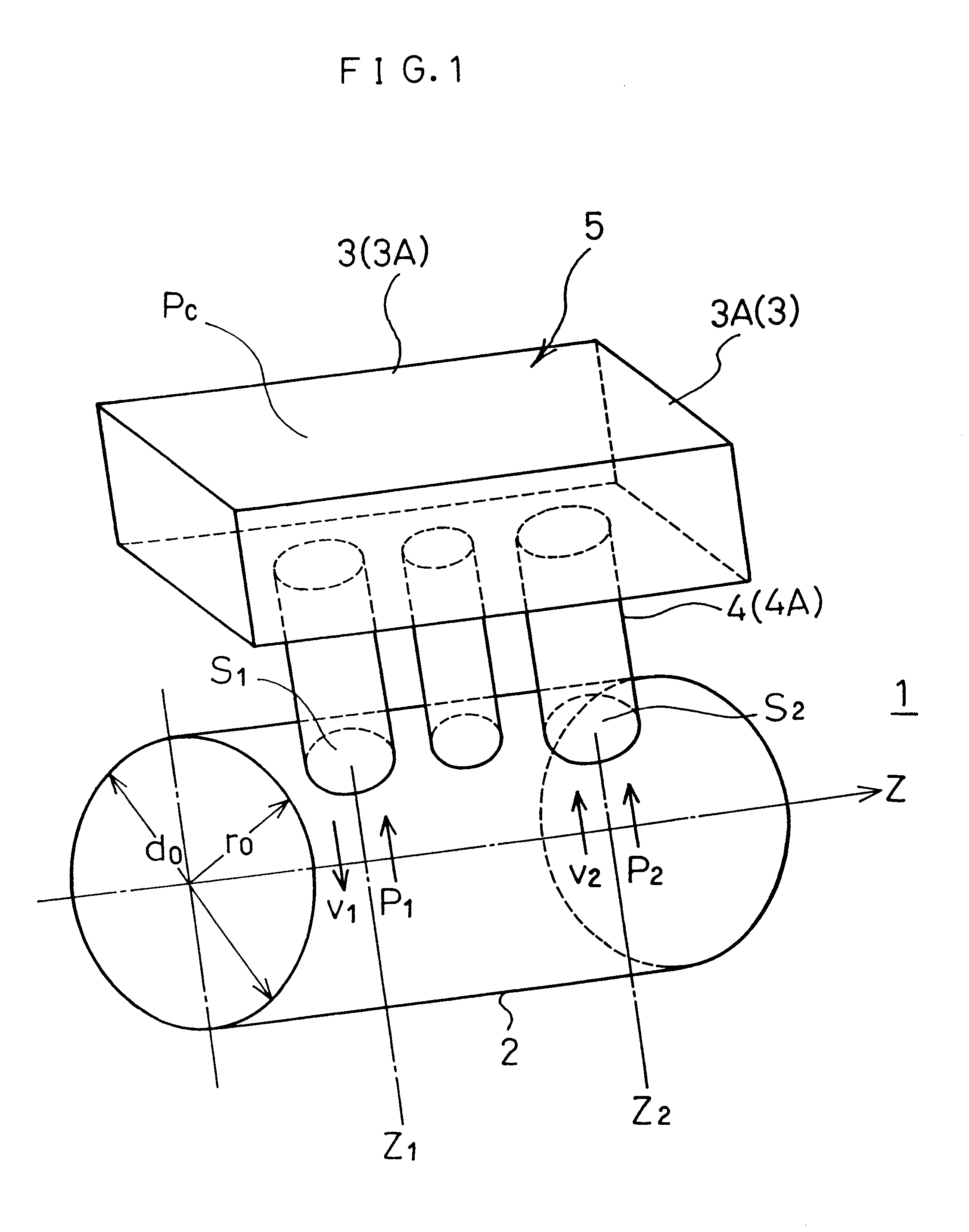

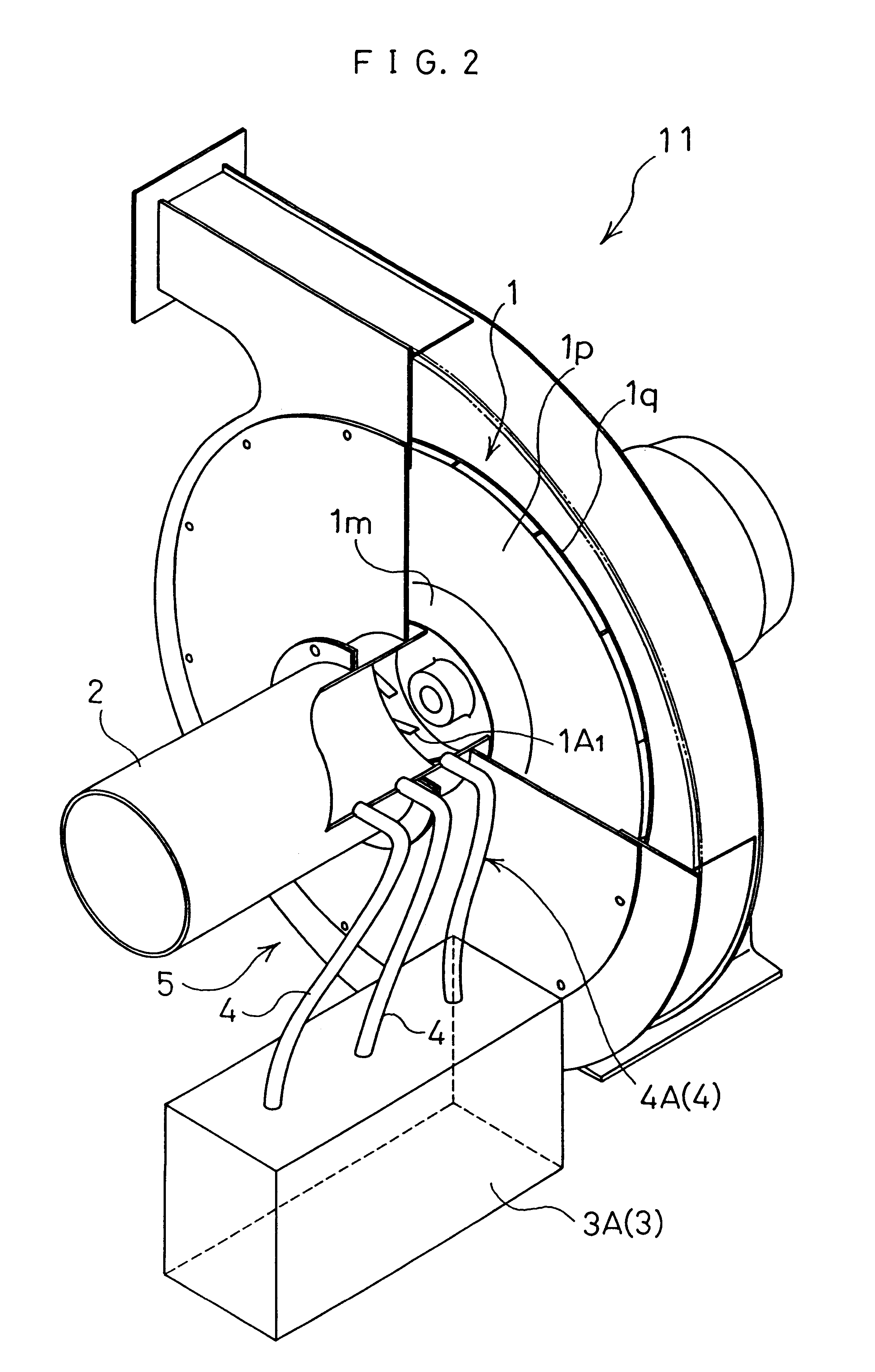

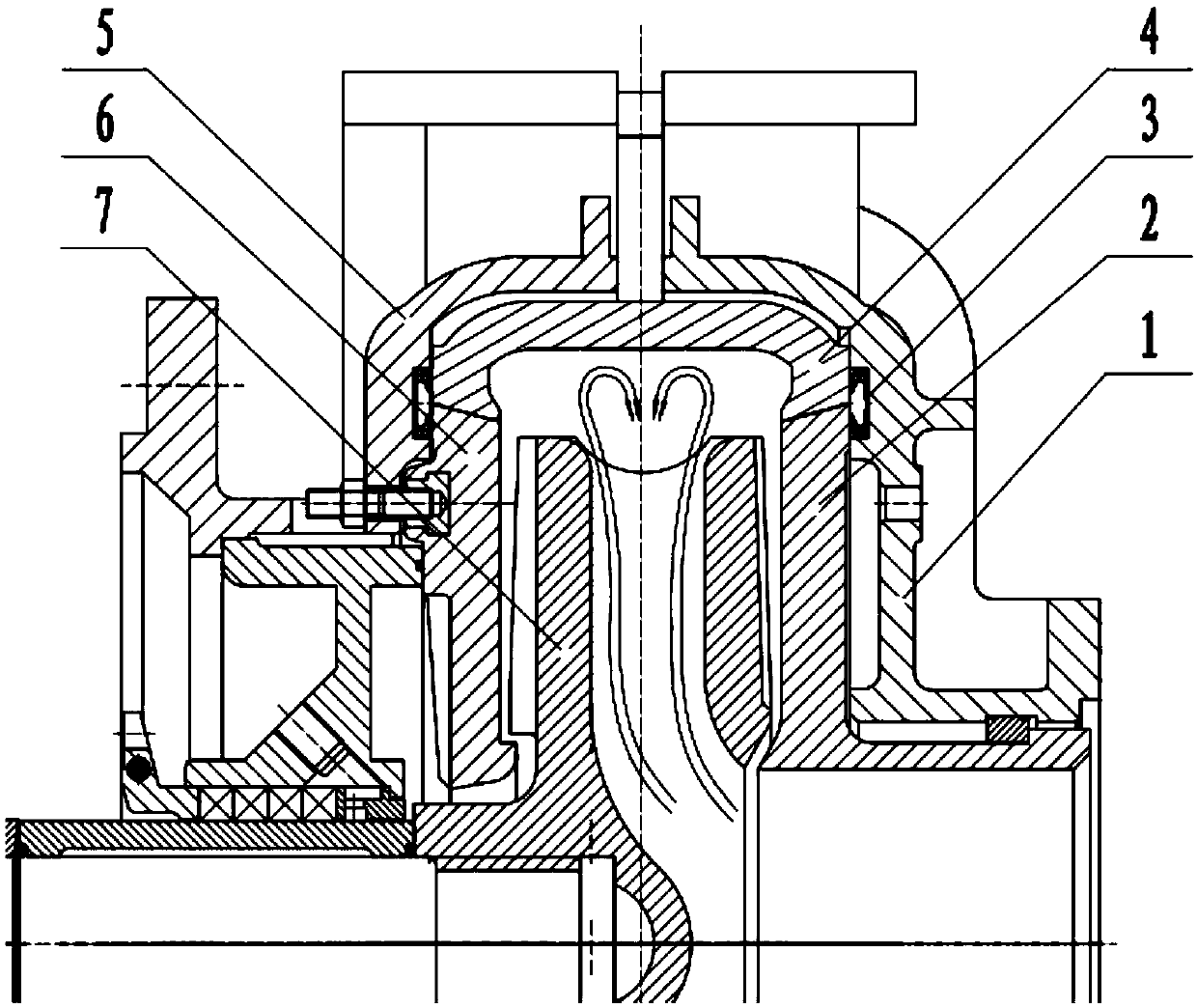

Suction flow preswirl control bypass structure for blowers

InactiveUS6190125B1Improve fan efficiencyReduce shaft powerPump componentsFluid dynamicsImpellerPressure rise

The objects of the present invention are to improve the fan efficiency by the decrease of the shaft power of a fan and / or the increase of the pressure rise owing to a fan impeller, which are accomplished by the rational control of the energy based on the tangential velocity of the prerotation flow generating at "the region ahead of an impeller' inside the suction pipe of a fan, and to reduce fan noise by the improvement of air flow at the portion in close vicinity to an impeller inside the suction pipe. The present invention is related to a by-pass unit (5) disposed upstream an impeller to control the energy generated by the air flowing into the impeller (1), comprising a specific region of a suction pipe (2) as a part of the by-pass unit (5), an air chamber (3), through which the air is able to pass, forming a closed spatial region outside the suction pipe (2), and communicating passages (4) for connecting the closed spatial region to the suction pipe (2).

Owner:SHOWA FURYOKU KIKAI

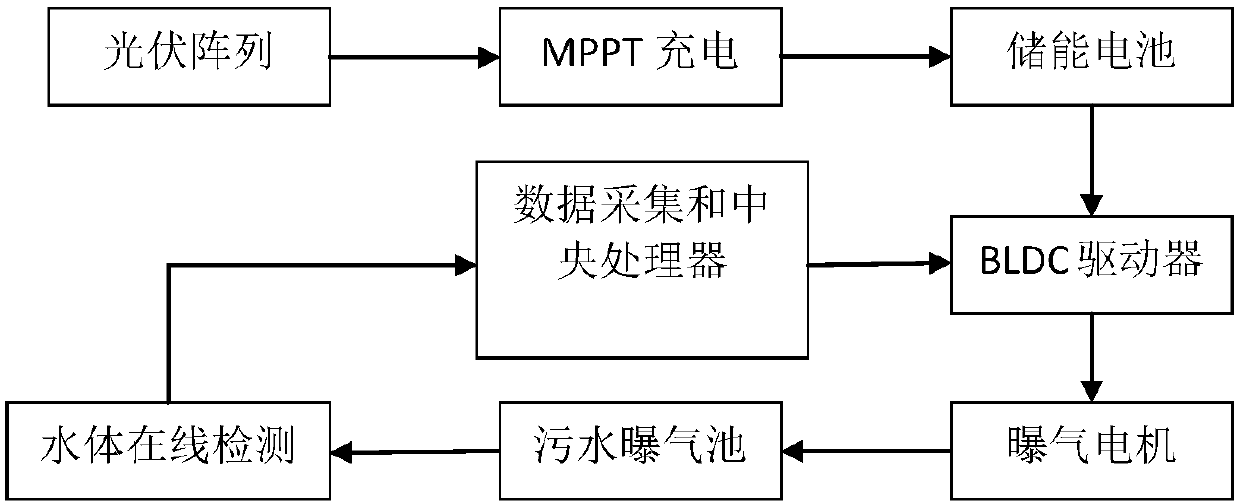

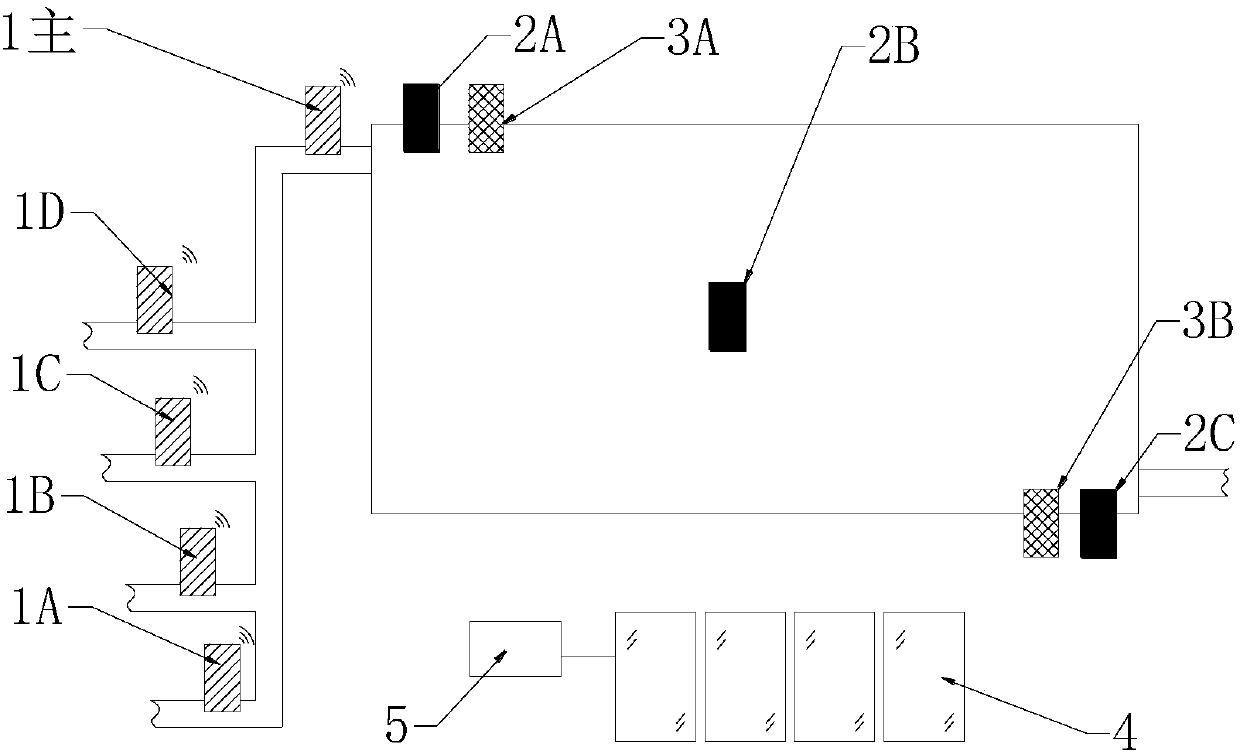

Aerating sewage treatment system and multi-parameter fuzzy control method thereof

PendingCN107628691ABest working powerImprove cleanlinessWater aerationSustainable biological treatmentTurbidityEngineering

The invention relates to an aerating sewage treatment system and a multi-parameter fuzzy control method thereof and aims to provide the aerating sewage treatment system and the multi-parameter fuzzy control method thereof. According to the system, photovoltaic cells are taken as energy sources, and a direct-current motor and an aeration machine are taken as executing mechanisms. The operation modeof the system comprises steps as follows: sewage flow is estimated by detecting liquid level values of a branch sewer and a main pipe as well as transmitted time difference; initial rotating speed ofthe motor is calculated according to the flow as well as conductivity value and turbidity value of a water inlet; after the system operates for a period of time, the conductivity value and the turbidity value of a water outlet are detected, a fuzzy control rule table is searched according to total quantity and change rate, real-time rotating speed of the motor is determined, and energy waste is avoided.

Owner:ZHEJIANG ENERGY & NUCLEAR TECH APPL RES INST

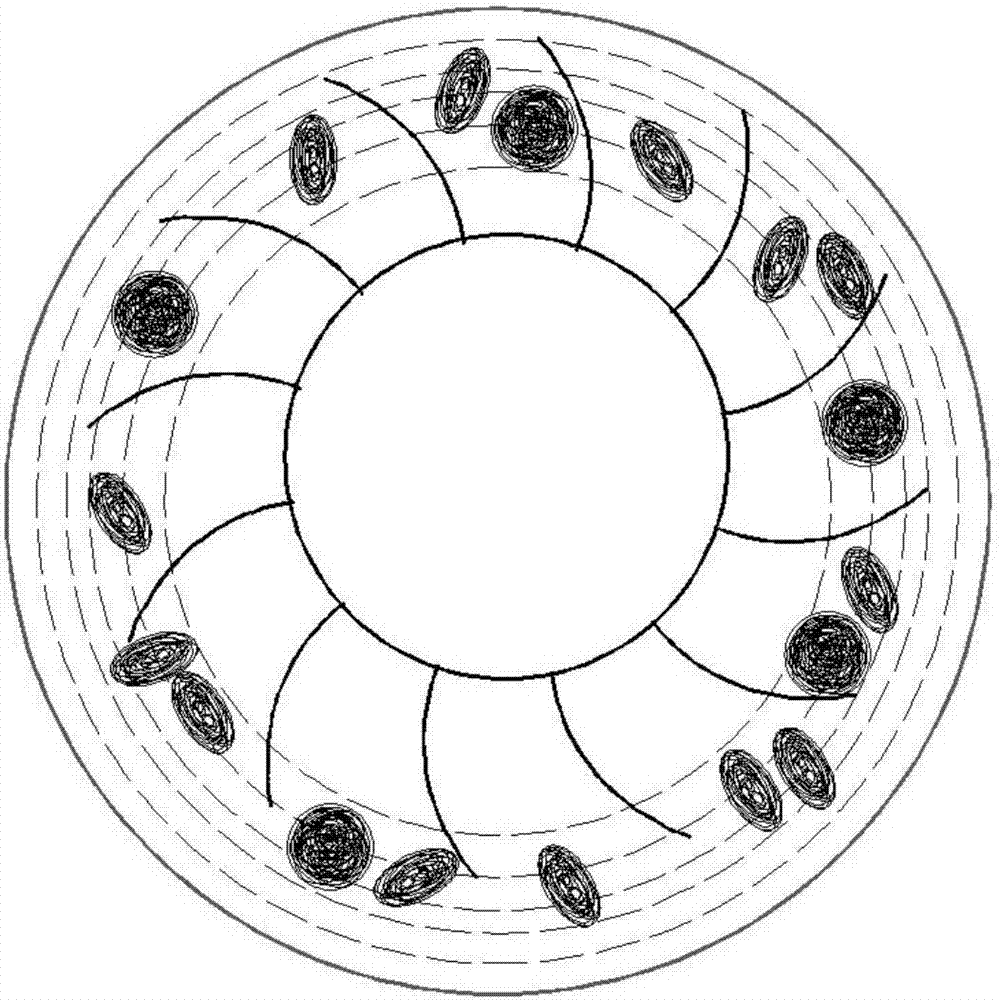

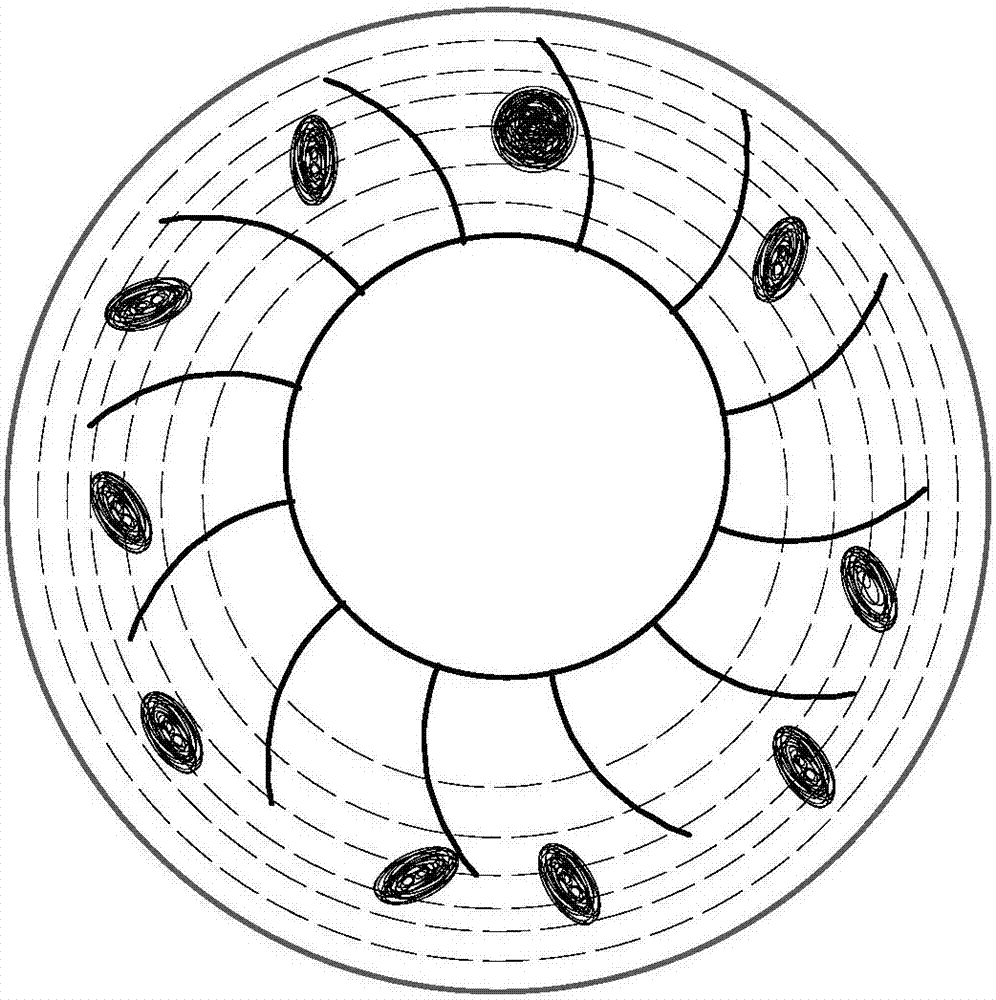

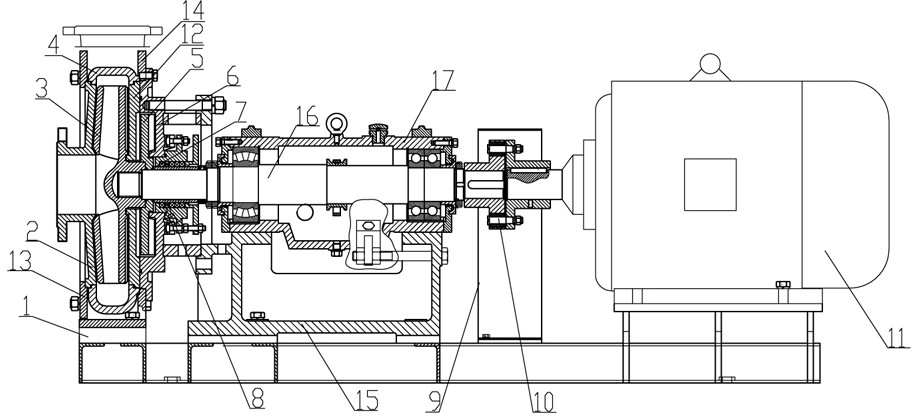

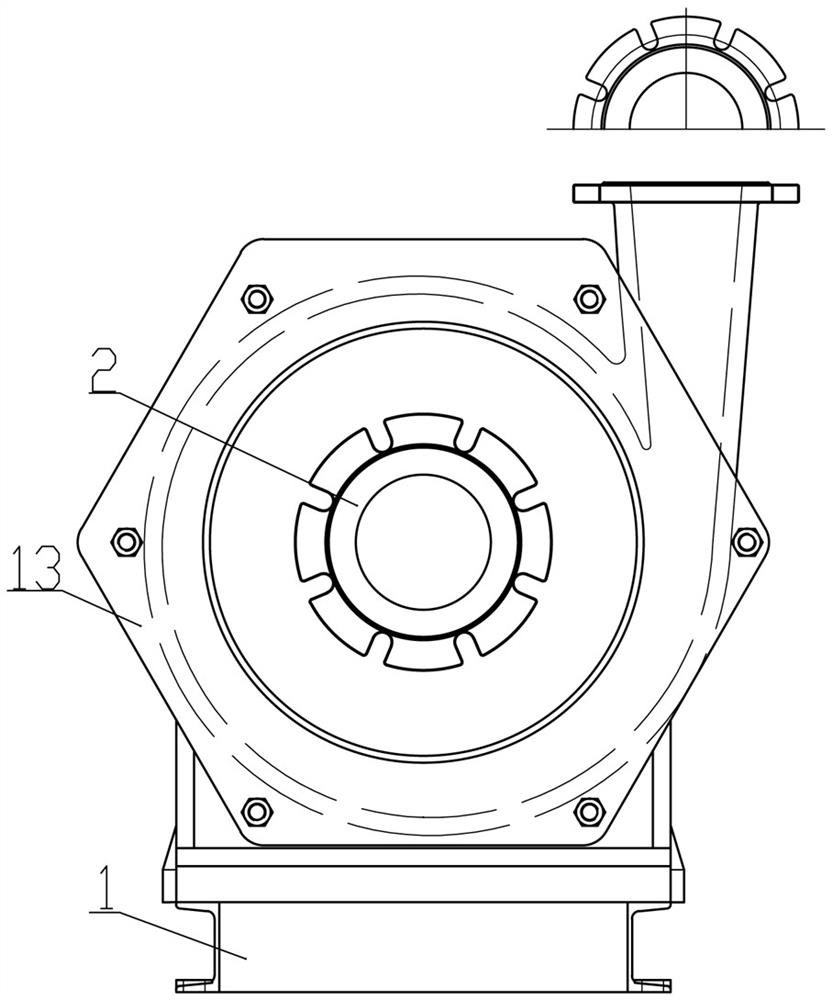

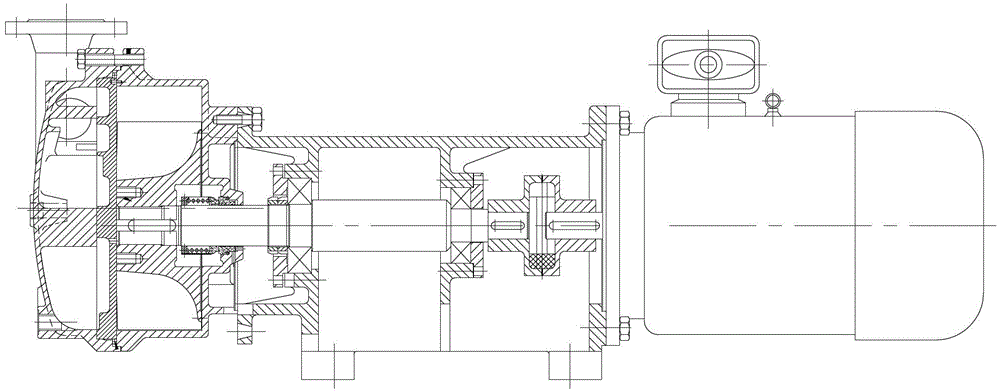

Impeller and slurry pump

PendingCN111997931AImprove hydraulic efficiencyImprove efficiencySpecific fluid pumpsPump componentsPhysicsElectric machinery

The invention relates to an impeller which comprises an impeller body. Multiple blades distributed in the circumferential direction are arranged on the impeller body; and each blade is gradually warped from the center of the impeller body to the edge part of the impeller body. The invention further relates to a slurry pump which comprises a welding bottom plate. A motor and a bracket are fixed onto the welding bottom plate; a shaft seal transmission part is arranged on the bracket; a pump shaft is connected into the shaft seal transmission part; a coupler is arranged at one end of the pump shaft; a pump body is arranged at the other end of the pump shaft; and the pump shaft is connected with the motor through the coupler. The slurry pump further comprises the impeller; a pump body is a sealed chamber; and the impeller is arranged in the chamber and is fixedly connected with the pump shaft. The impeller and the slurry pump provided by the invention are reasonable in structure design andbeneficial to improving the efficiency of the pump.

Owner:郑州联兴冶金设备有限公司

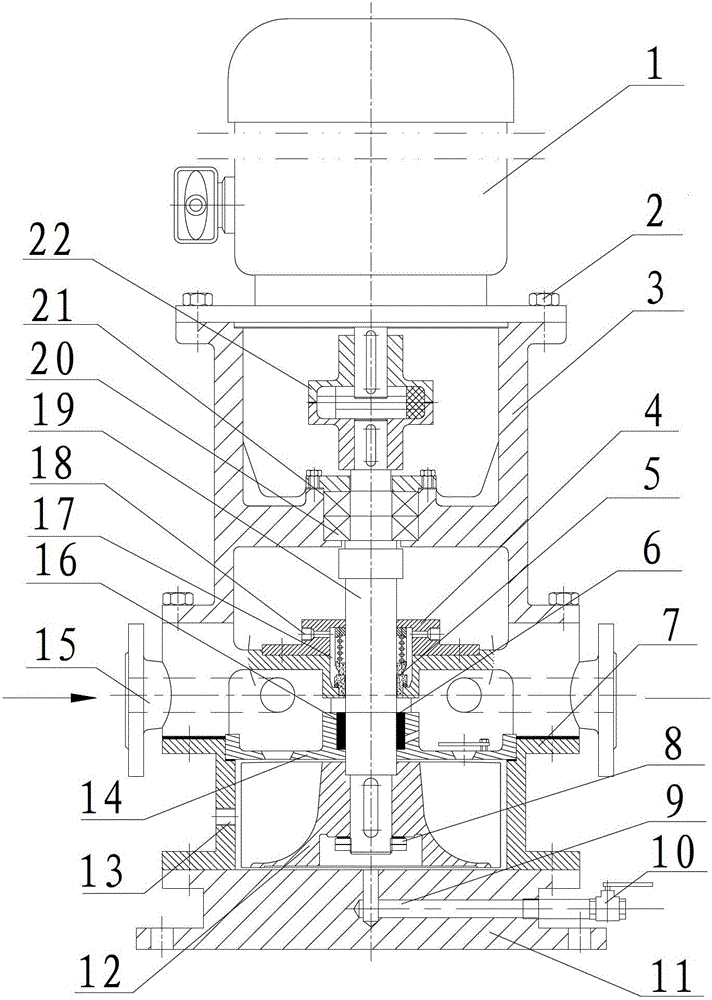

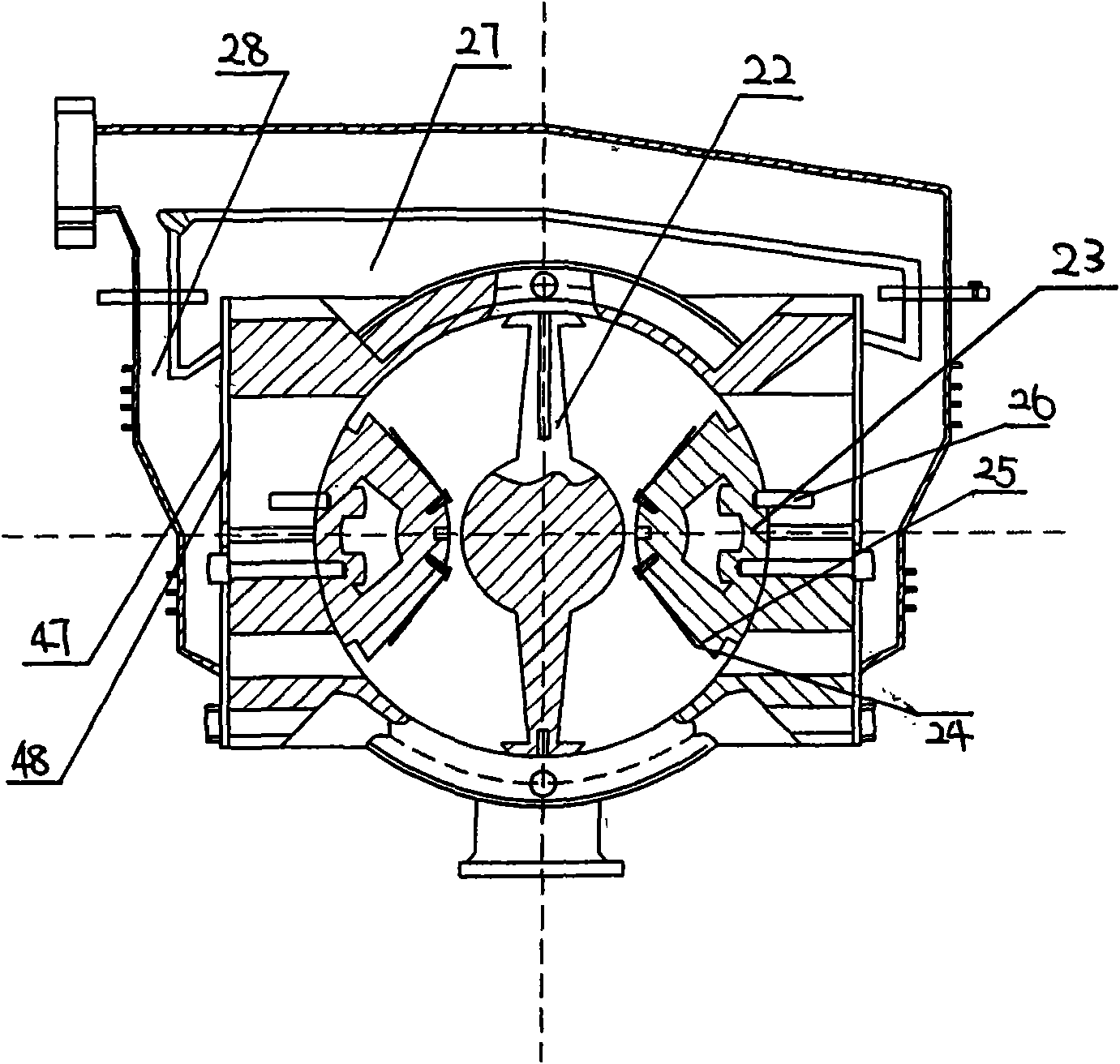

Vertical water ring vacuum pump

ActiveCN103388589BImprove work efficiencyReduce energy consumptionPump componentsRadial flow pumpsCircular discImpeller

The invention relates to a vacuum obtaining device, and in particular relates to a vertical water ring vacuum pump. The vertical water ring vacuum pump comprises a stator part, a rotor part, a bracket and a motor, wherein the stator part comprises a base, a pump body, a distributing round disc and a pump cover. The rotor part comprises a pump shaft and an impeller, wherein the rotor part is vertical to the horizontal plane. Eccentric distance e between the rotor part and the distributing round disc on the horizontal panel along the direction vertical to the central line of an air inlet is arranged. The pump shaft sequentially penetrates through the bracket, the pump cover, the distributing round disc and the pump body from top to bottom. The motor is connected with the pump shaft through a coupler for transmitting torque. The impeller is suspended in an inner cavity of the pump body. The vertical water ring vacuum pump provided by the invention is simple in structure, convenient to manufacture and install, low in manufacturing cost, small in occupied area and high in work efficiency.

Owner:鲁阳精工真空科技(淄博)有限公司

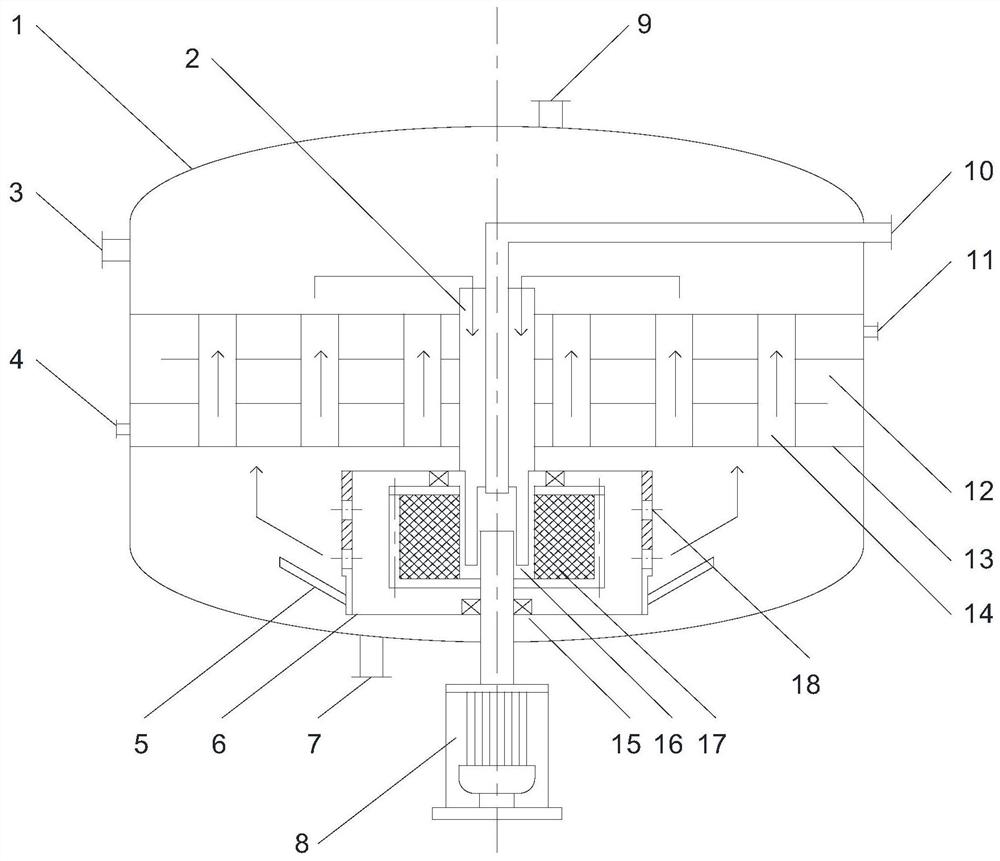

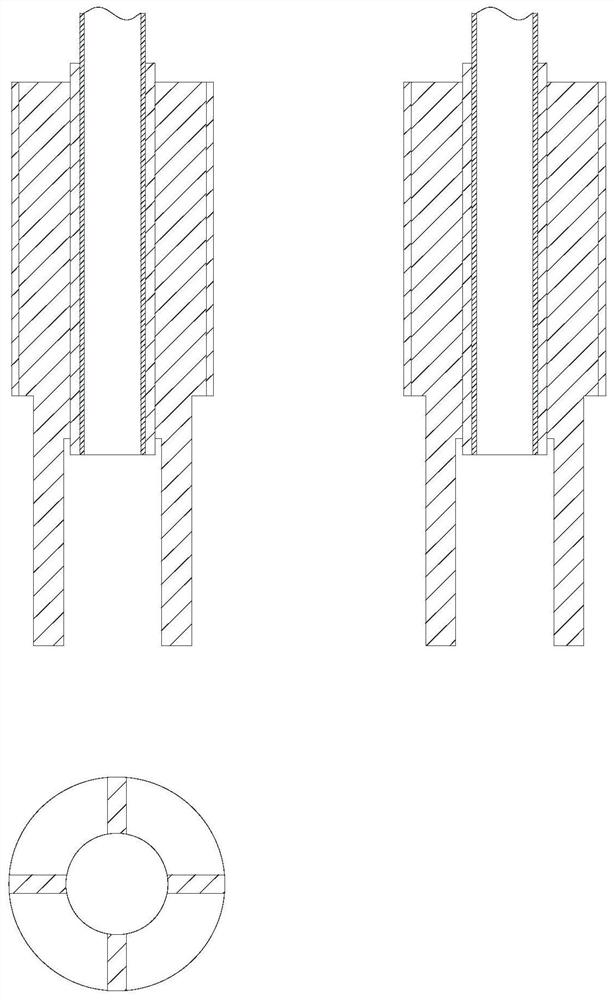

Immersed rotating filling bed reactor and application

ActiveCN113477188AReduce mixImprove the mixing effectWater contaminantsChemical/physical processesThermodynamicsReaction rate

The invention discloses an immersed rotating filling bed reactor and application. The immersed rotating filling bed reactor is characterized in that a rotor filler is immersed in materials in the reactor, the materials in the reactor form circulation under the driving of rotation of a rotor, the materials are fully sheared and dispersed into fluid infinitesimal elements when passing through the filler, the mass transfer rate and the reaction rate are enhanced, a feeding assembly enables different-phase materials to be led to the inner edge of the rotor at the same time, a blocking ring and a baffle play a vortex breaking role, and a heat exchange assembly can keep the system within a proper temperature range. According to the invention, the immersed rotating filling bed reactor is suitable for gas-liquid, liquid-liquid and other heterogeneous systems, and compared with a traditional rotating filling bed, the material contact time is long, and the reaction is more sufficient.

Owner:BEIJING UNIV OF CHEM TECH

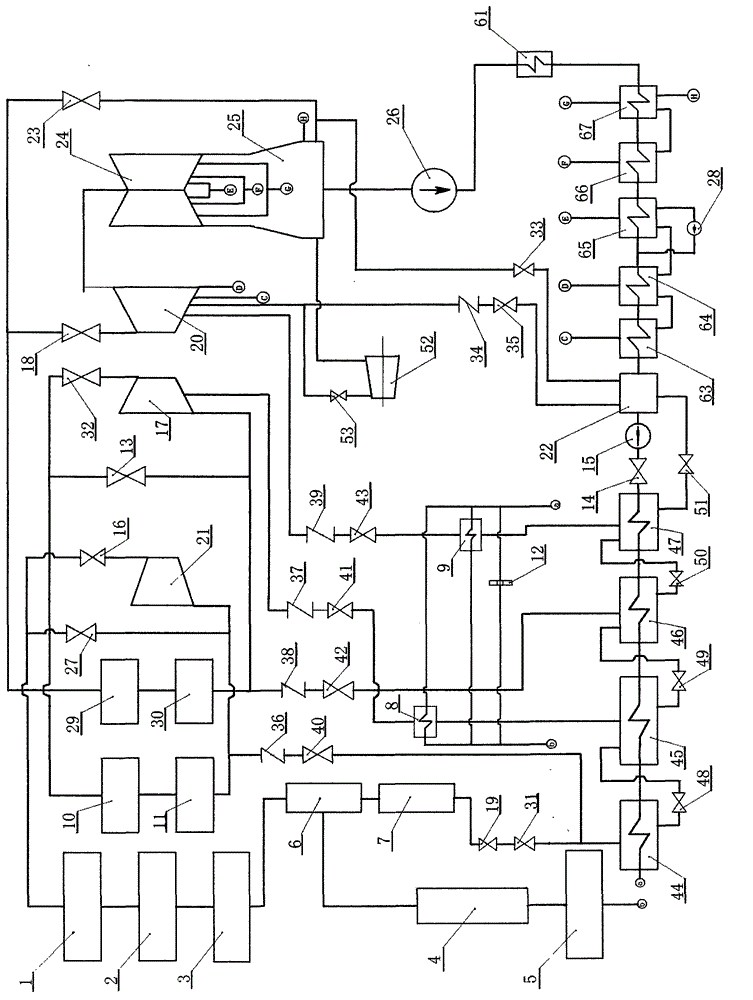

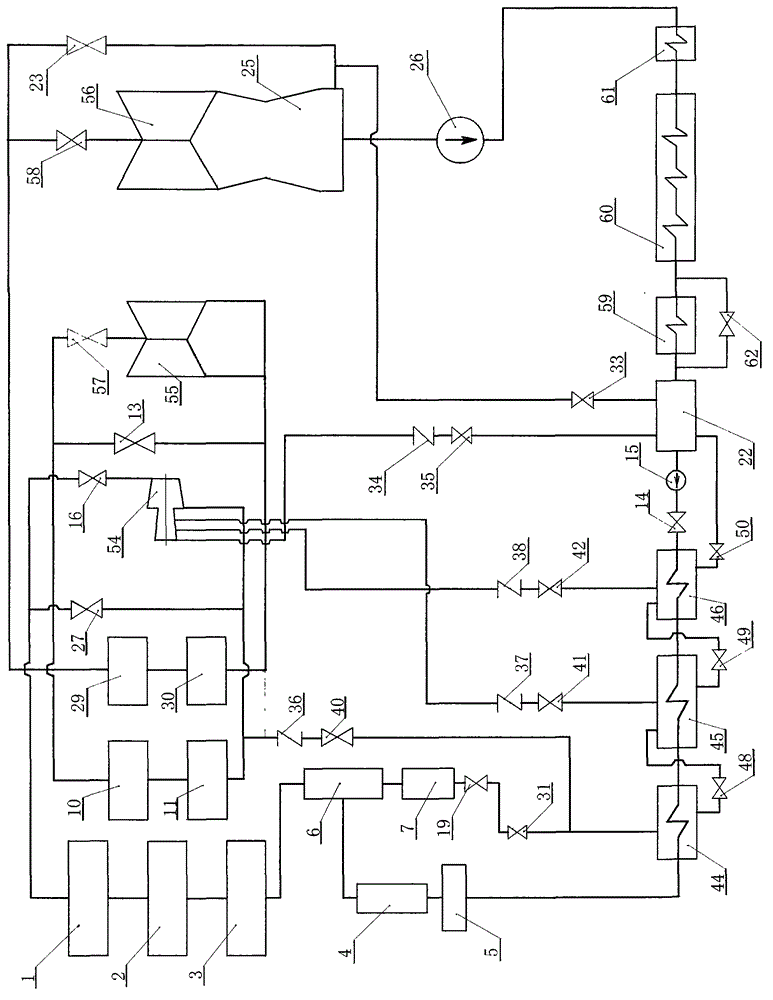

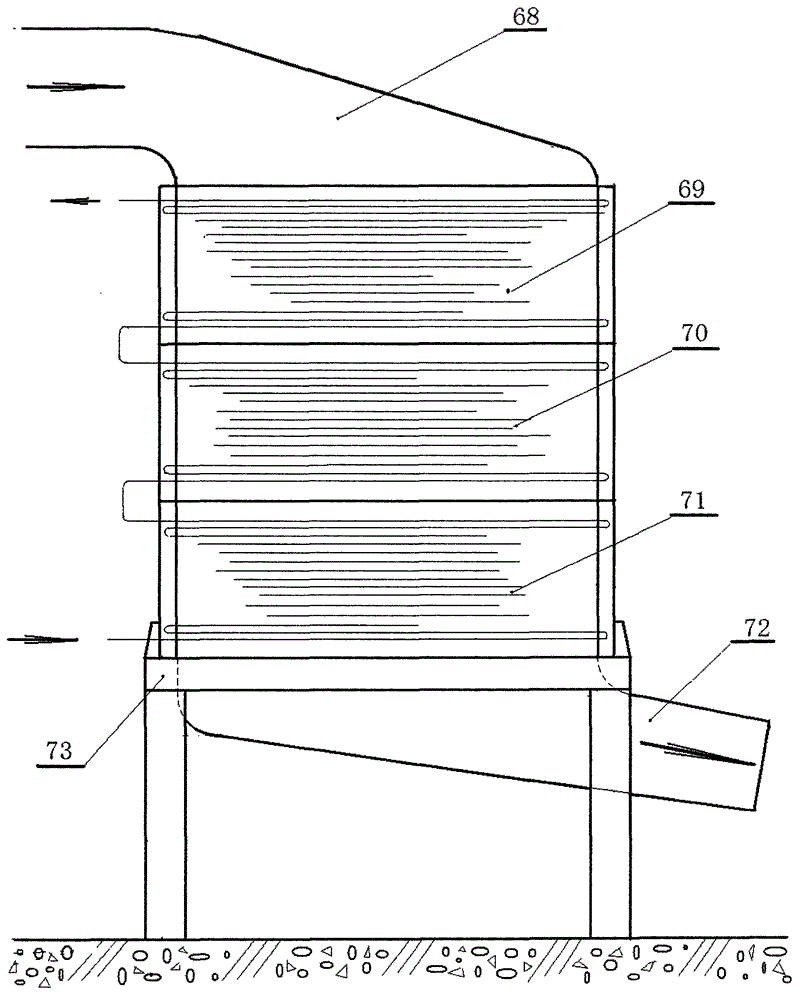

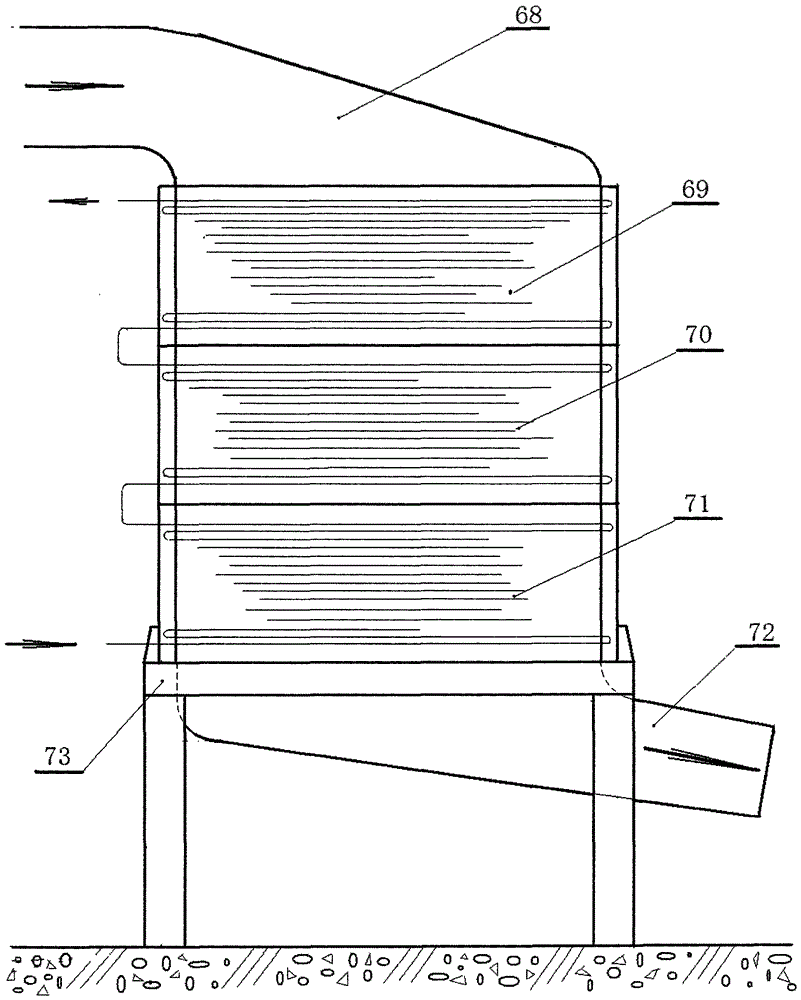

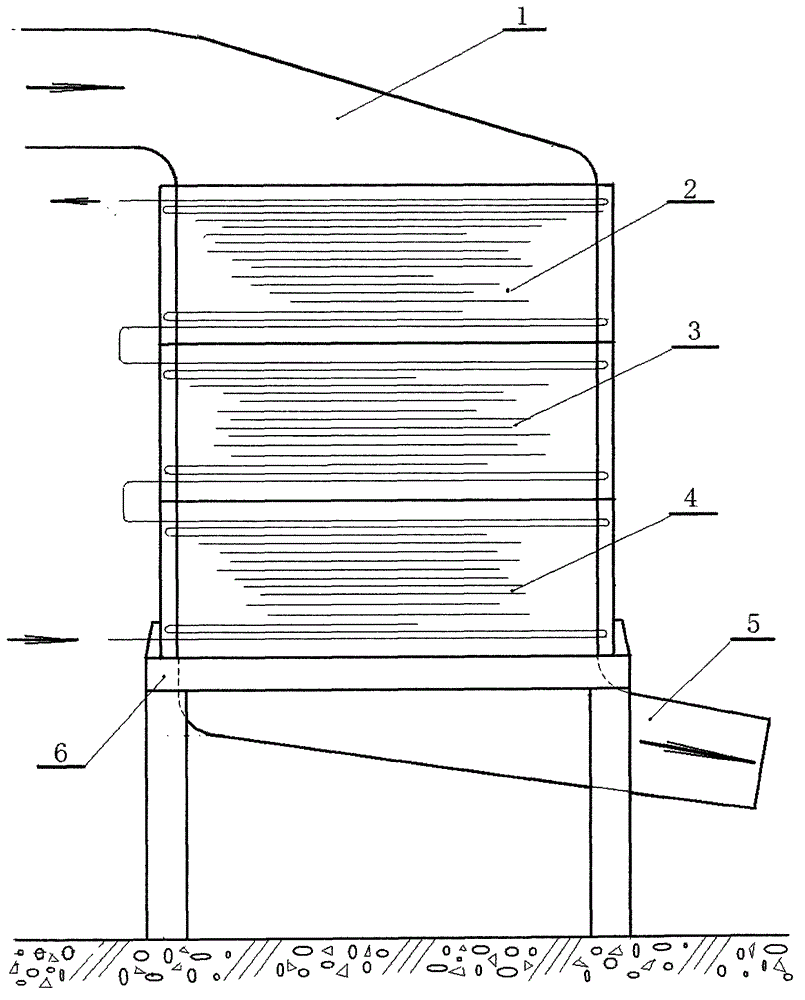

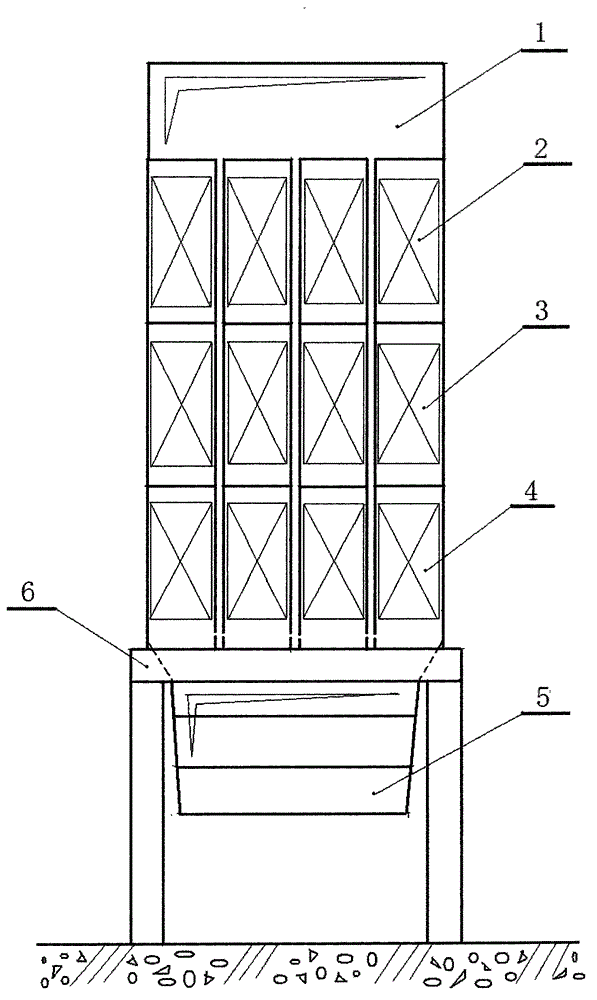

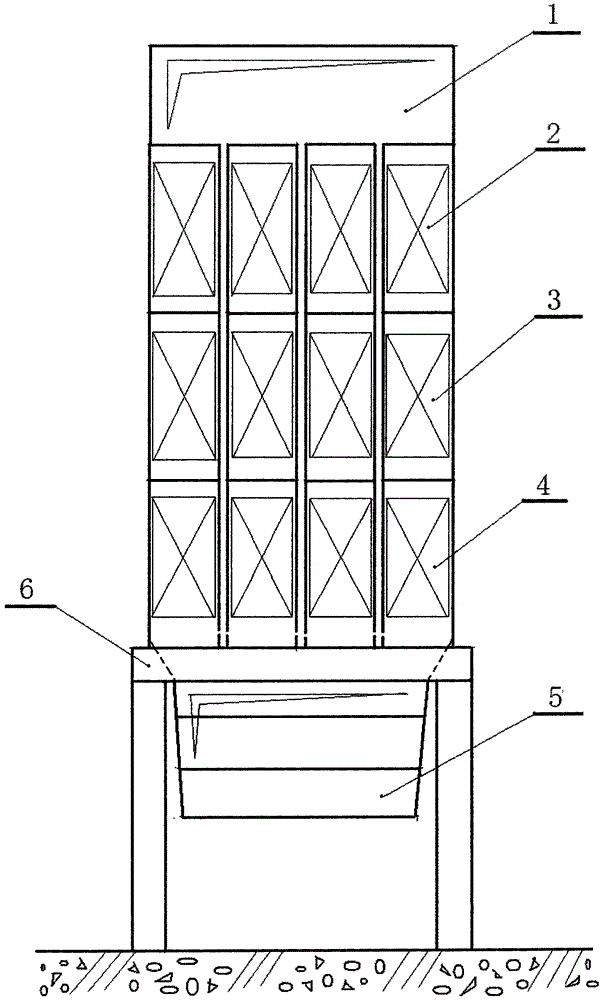

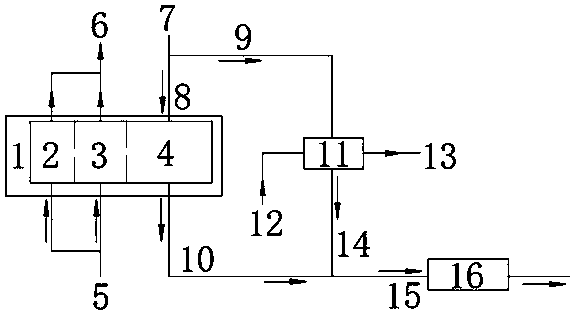

Ultra-low temperature coal economizer for secondary reheat unit

ActiveCN104864383AReduce heat consumptionSignificant thermoeconomic benefitsCombustion technology mitigationFeed-water heatersEvaporationEngineering

The invention discloses an ultra-low temperature coal economizer for a secondary reheat unit, and relates to a low-pressure coal economizer which is used for a secondary reheat coal-fired generating unit and can replace a low pressure heater to heat condensation water and recycle latent heat of vaporization of vapor contained in partial exhaust gas. The condensation water which is at 35 DEG C or a lower temperature is utilized to absorb almost half of evaporation heat of the vapor contained in the exhaust gas, and the temperature of the exhaust gas is dropped to 50 DEG C. Compared with the prior art, the ultra-low temperature coal economizer does not push out partial certain level vapor extraction, but completely replace the low pressure heater; the water side resistance of the ultra-low temperature coal economizer is far lower than the sum of the water side resistance of four or five sets of the low pressure heater, and the shaft power of a condensate pump is obviously deceased; due to the fact that the temperature of the exhaust gas which enters a desulfurization tower is obviously decreased, the process water consumption is greatly reduced, the volume flow of the exhaust gas is obviously reduced, and the power consumption of an induced draft fan is obviously decreased; the vapor can absorb most of PM2.5, SO3 and NOx in the exhaust gas in the condensation heat release process, and micro-discharge is facilitated for the coal-fired generating unit.

Owner:章礼道

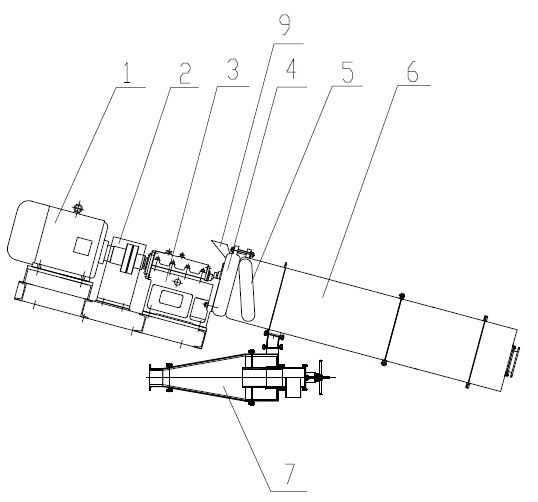

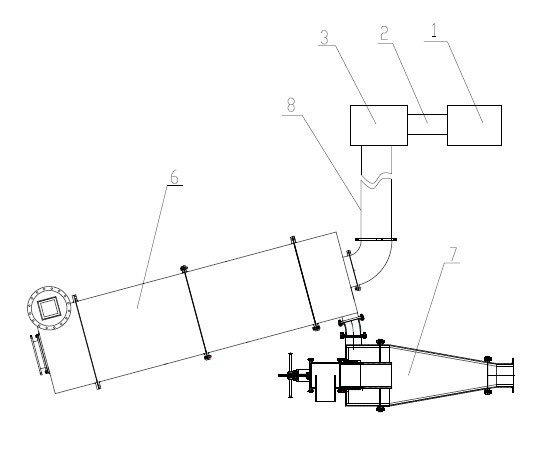

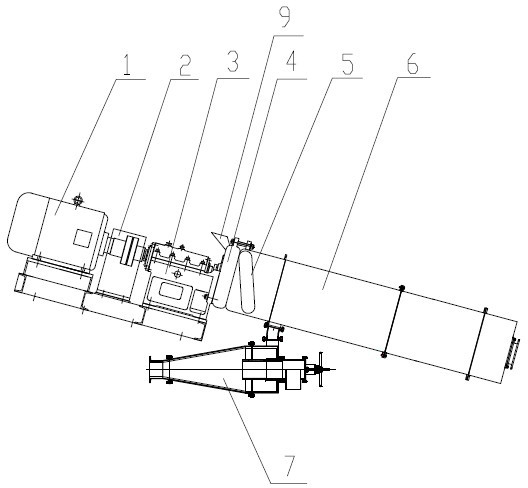

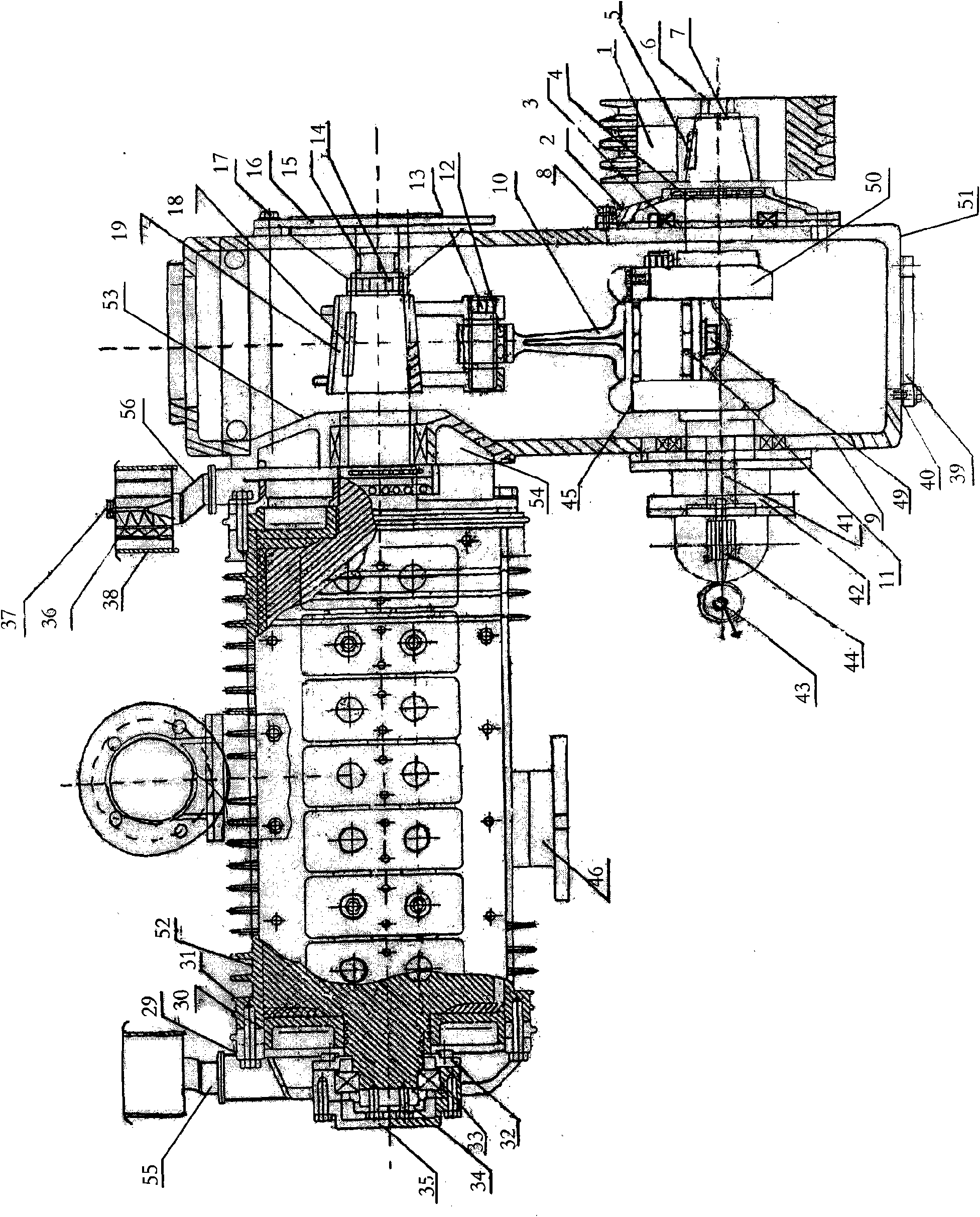

Coal dressing separator

The invention discloses a coal dressing separator, and relates to the technical field of a centrifuge, comprising a motor, a torque flow pump, a first-stage swirler and a second-stage swirler, wherein the motor is connected with the torque flow pump by a shaft coupler, the head of the torque flow pump is fixedly connected with the first-stage swirler, a housing on the head of the torque flow pump and the first-stage swirler are designed into a whole, and a material outlet of the pump directly enters into the first-stage swirler, so that the massive middle wear-resistant pipes, elbows, valves and the like in the conventional connection mode between the pump and the first-stage swirler can be saved, and the production, manufacture and maintenance cost of the equipment can be greatly reduced; the lift of the pump can be shortened, so that the shaft power of the pump can be greatly reduced, and the energy saving effect is obvious; and the evenly-mixed raw material can directly enter into the first-stage swirler at the same speed due to the device, so that the raw coal dressing effect can be improved. Furthermore, the separator is smaller in volume, and more compact in structure, and a pipeline between the torque flow pump and the first-stage swirler is better in air impermeability and high in safety since the used pipeline is shorter.

Owner:HEBEI JINRUN MINE EQUIP GRP CO LTD

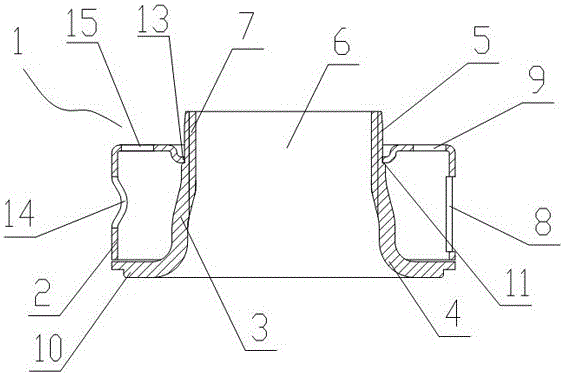

Water outlet body structure

The invention discloses a water outlet body structure which comprises a water outlet main body. The water outlet main body comprises a water outlet body cover and a water outlet body liner. The water outlet body liner is sleeved with the water outlet body cover which is connected with the outer wall of the water outlet body liner in a clamped mode. The water outlet body liner comprises a water inlet end and a water outlet end. The water outlet end protrudes out of the water outlet body cover. A fluid cavity of a smooth step structure is formed in the water outlet body liner. Internal threads are formed in the portion, at one end of the water outlet end, of the cavity wall of the fluid cavity. At least two notches are evenly distributed in the side face of the water outlet body cover circumferentially. Through holes are formed in the portions, corresponding to the notches, of the end face of the water outlet body cover. By means of the water outlet body structure, it can be ensured that smooth transition is adopted for the streamline of the fluid cavity, a good diversion effect is achieved, the effect of reducing hydraulic loss is achieved through the regular area change of collected water, the high-flow lift and efficiency are remarkably improved, the shaft power is reduced, the work efficiency of a pump is improved, and cost is reduced.

Owner:NANFANG PUMP IND

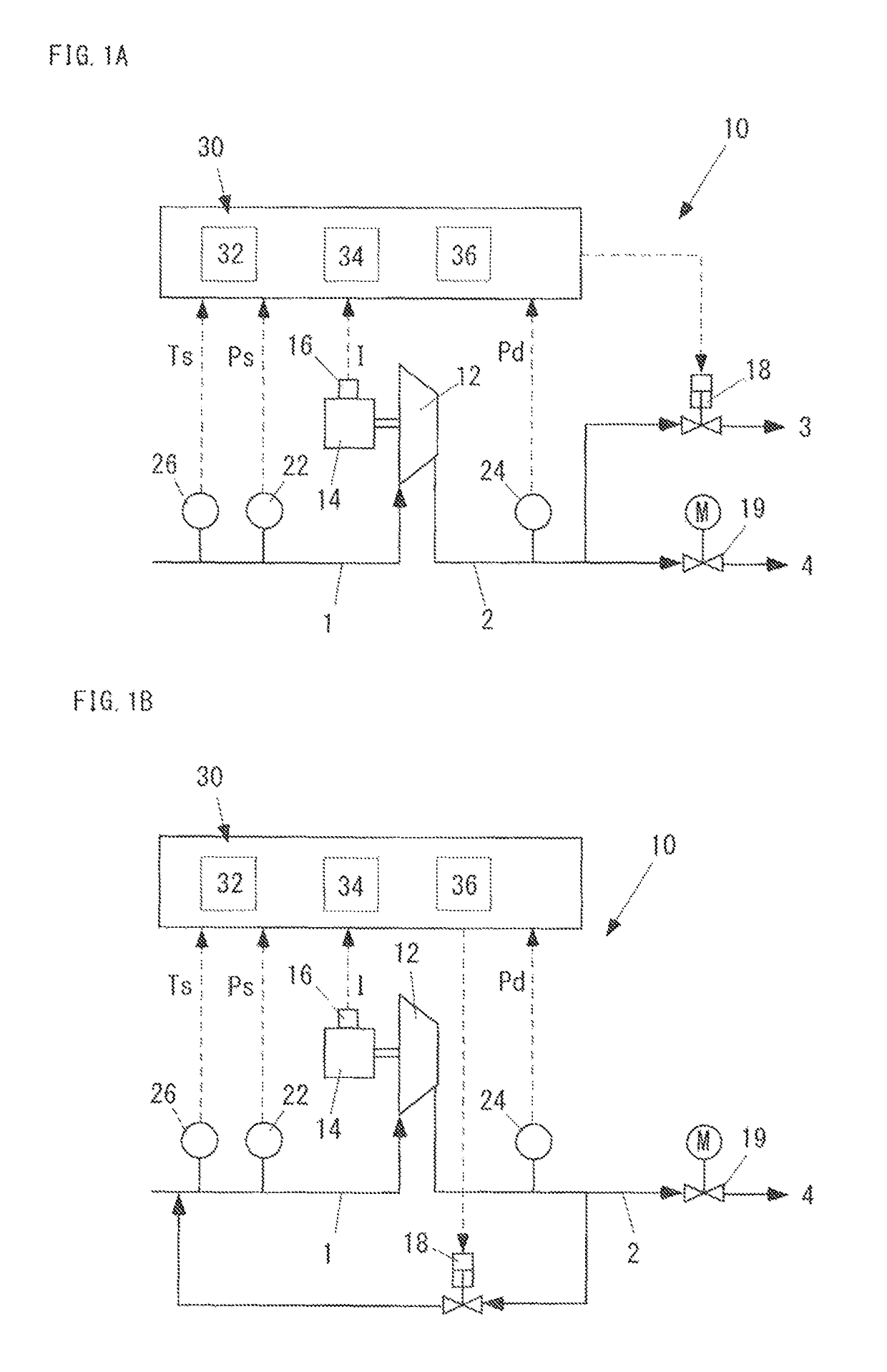

Centrifugal compressor apparatus and method for preventing surge therein

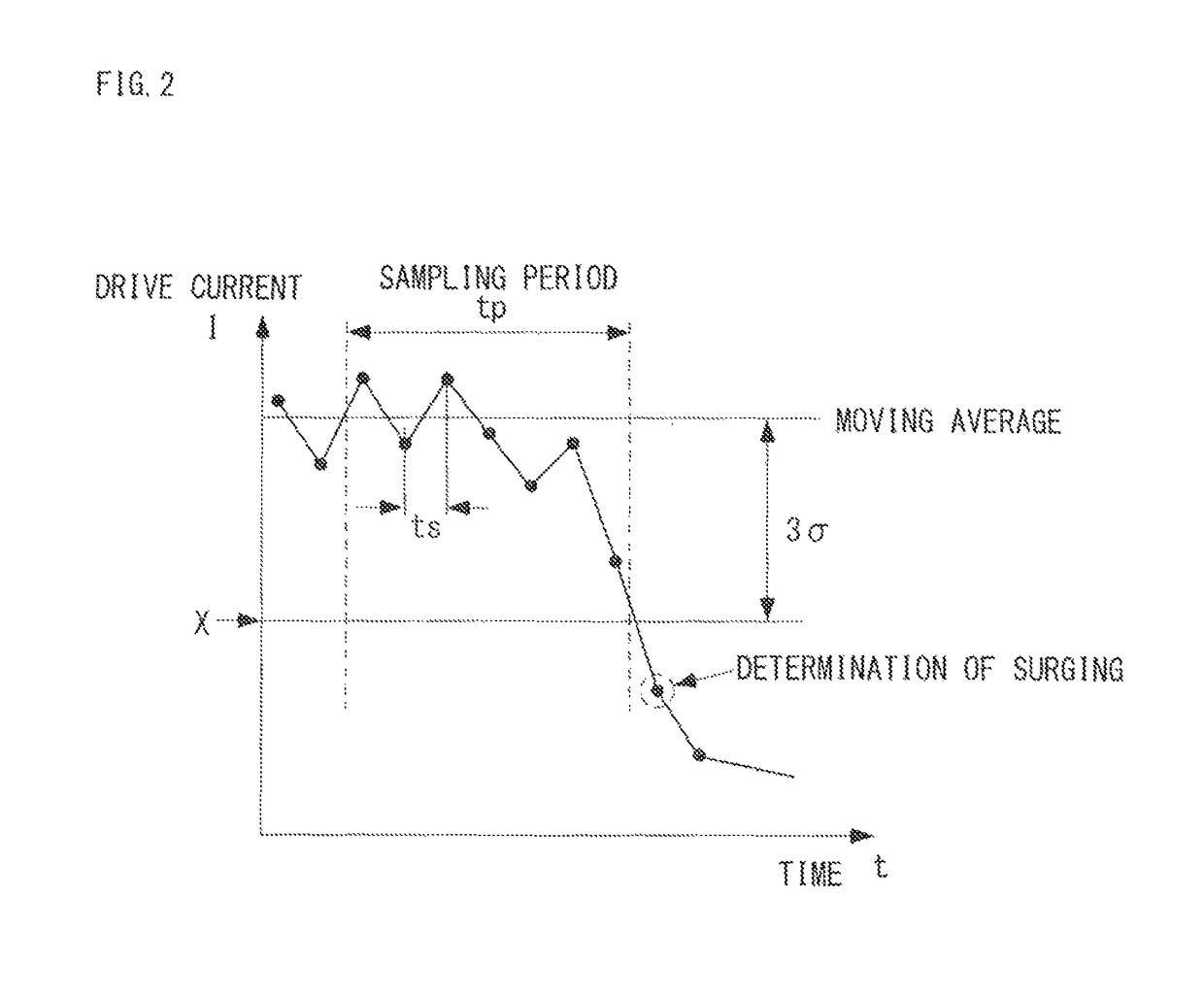

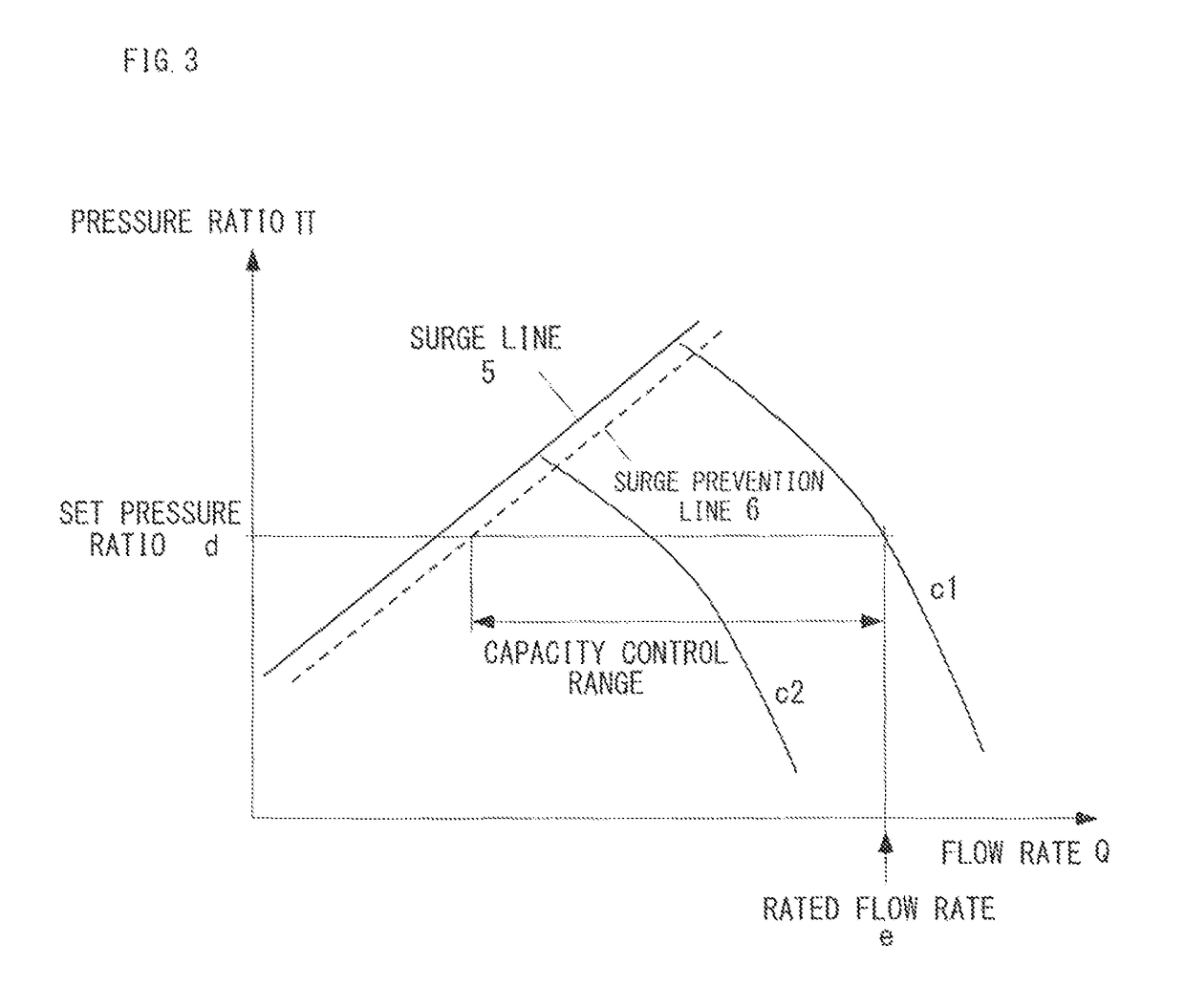

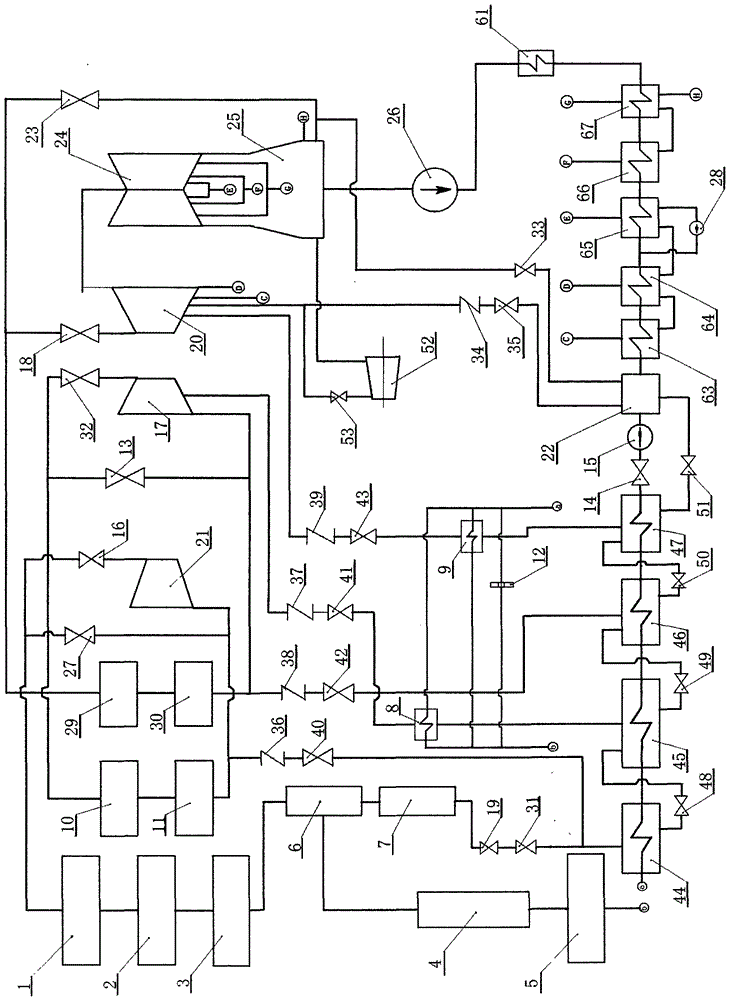

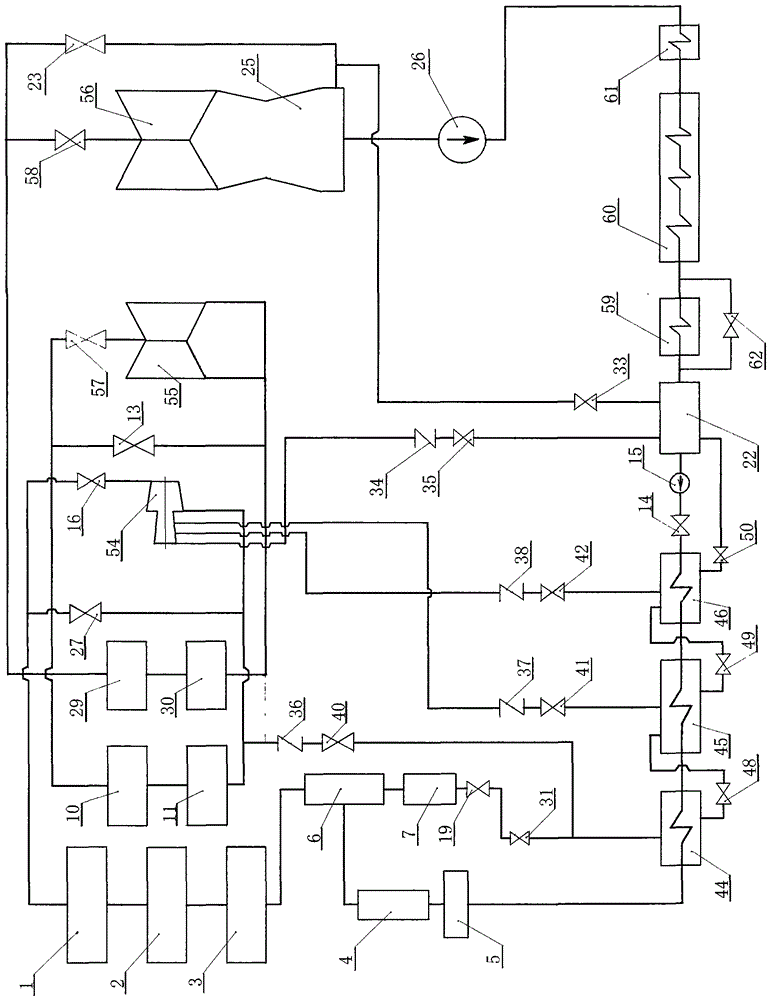

ActiveUS10202980B2Reduce shaft powerReliable detectionPump componentsEngine controlDriving currentMoving average

There is provided a centrifugal compressor apparatus including a centrifugal compressor that centrifugally compresses a gas, an electric motor that rotatably drives the centrifugal compressor, a current detector that detects a drive current I of the electric motor, and an exhaust valve that discharges a compressed gas to a lower pressure section. The centrifugal compressor apparatus (A) detects the drive current I at a sampling cycle ts, (B) updates, as a current threshold, in real time, a value “(moving average)−n×(standard deviation)” for which a plurality of drive currents measured in a sampling period tp serves as a population, where n is a positive number in the range of 3 to 4 and, (C) determines that surging has occurred when the exhaust valve is closed and the drive current I is below the current threshold X, and (D) further opens the exhaust valve to discharge the compressed gas when determining that surging has occurred.

Owner:IHI ROTATING MACHINERY ENG CO LTD

Ultra-low temperature economizer for double reheat unit

ActiveCN104864383BReduce heat consumptionSignificant thermoeconomic benefitsCombustion technology mitigationFeed-water heatersEvaporationEngineering

The invention discloses an ultra-low temperature coal economizer for a secondary reheat unit, and relates to a low-pressure coal economizer which is used for a secondary reheat coal-fired generating unit and can replace a low pressure heater to heat condensation water and recycle latent heat of vaporization of vapor contained in partial exhaust gas. The condensation water which is at 35 DEG C or a lower temperature is utilized to absorb almost half of evaporation heat of the vapor contained in the exhaust gas, and the temperature of the exhaust gas is dropped to 50 DEG C. Compared with the prior art, the ultra-low temperature coal economizer does not push out partial certain level vapor extraction, but completely replace the low pressure heater; the water side resistance of the ultra-low temperature coal economizer is far lower than the sum of the water side resistance of four or five sets of the low pressure heater, and the shaft power of a condensate pump is obviously deceased; due to the fact that the temperature of the exhaust gas which enters a desulfurization tower is obviously decreased, the process water consumption is greatly reduced, the volume flow of the exhaust gas is obviously reduced, and the power consumption of an induced draft fan is obviously decreased; the vapor can absorb most of PM2.5, SO3 and NOx in the exhaust gas in the condensation heat release process, and micro-discharge is facilitated for the coal-fired generating unit.

Owner:章礼道

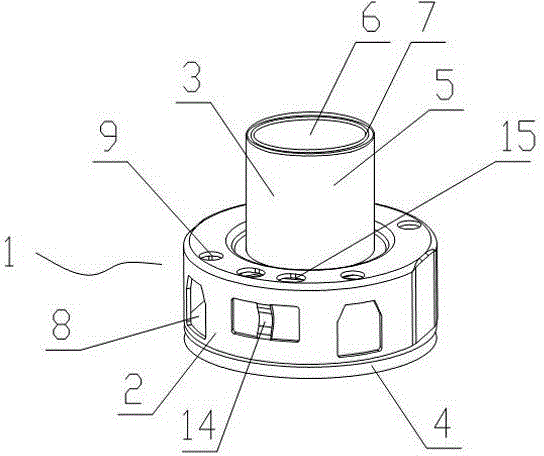

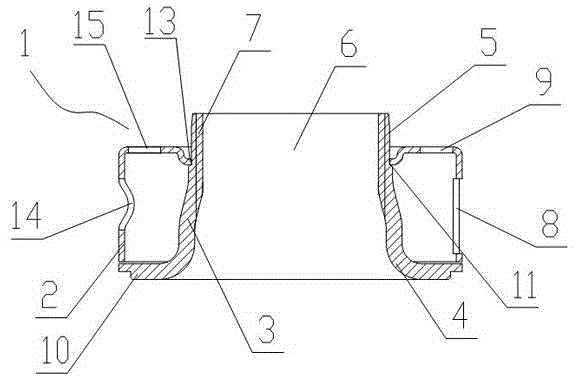

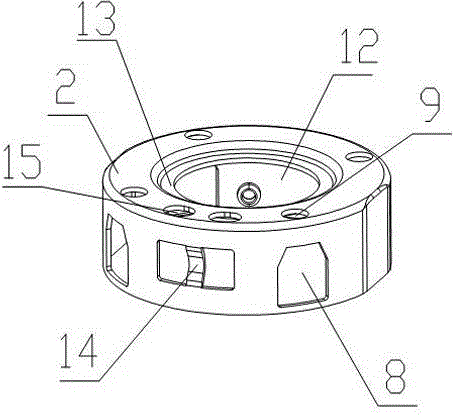

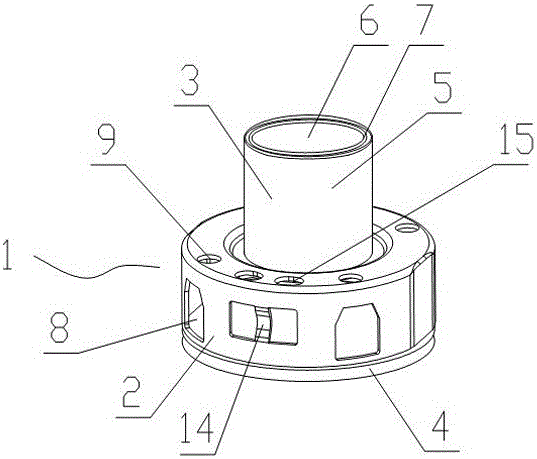

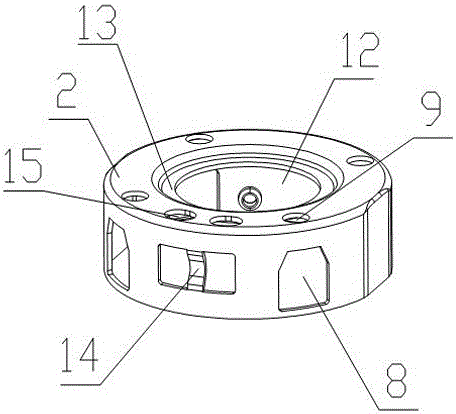

Impurity in-pump vortex impeller

InactiveCN109681436AReduce wearReduce concentrationPump componentsCircumferential flow pumpsImpellerEngineering

The invention provides an impurity in-pump vortex impeller. The impurity in-pump vortex impeller comprises a pump cover and a pump body, wherein the pump body is located at the top side of the pump cover; the pump cover is movably connected with the pump body; a front cover plate and a rear cover plate are movably mounted in an inner cavity of the pump body; the front cover plate and the rear cover plate are clamped with each other; a sheath is movably connected with the tops of the front cover plate and the rear cover plate; an impeller is fixedly mounted in the inner cavity of the front cover plate and the rear cover plate; an outlet of the impeller is designed into a concave shape so that the speed of the front cover plate and the rear cover plate at two sides of the impeller is greaterthan a middle speed; slurry is divided into two paths of fluid at the outlet and is rotated toward the center, so that particles are enforced to flow toward the center and a vortex shape is formed; furthermore, the concentration at two sides is reduced, so that the abrasion to a flow channel of the pump body and two side walls is alleviated and the service life of overflowing parts is prolonged;and the abrasion loss is reduced, the efficiency of a water pump is improved, the shaft power is reduced and the aim of energy saving and environment protection is directly realized.

Owner:SANLIAN PUMP IND CO LTD

a water body structure

The invention discloses a water outlet body structure which comprises a water outlet main body. The water outlet main body comprises a water outlet body cover and a water outlet body liner. The water outlet body liner is sleeved with the water outlet body cover which is connected with the outer wall of the water outlet body liner in a clamped mode. The water outlet body liner comprises a water inlet end and a water outlet end. The water outlet end protrudes out of the water outlet body cover. A fluid cavity of a smooth step structure is formed in the water outlet body liner. Internal threads are formed in the portion, at one end of the water outlet end, of the cavity wall of the fluid cavity. At least two notches are evenly distributed in the side face of the water outlet body cover circumferentially. Through holes are formed in the portions, corresponding to the notches, of the end face of the water outlet body cover. By means of the water outlet body structure, it can be ensured that smooth transition is adopted for the streamline of the fluid cavity, a good diversion effect is achieved, the effect of reducing hydraulic loss is achieved through the regular area change of collected water, the high-flow lift and efficiency are remarkably improved, the shaft power is reduced, the work efficiency of a pump is improved, and cost is reduced.

Owner:NANFANG PUMP IND

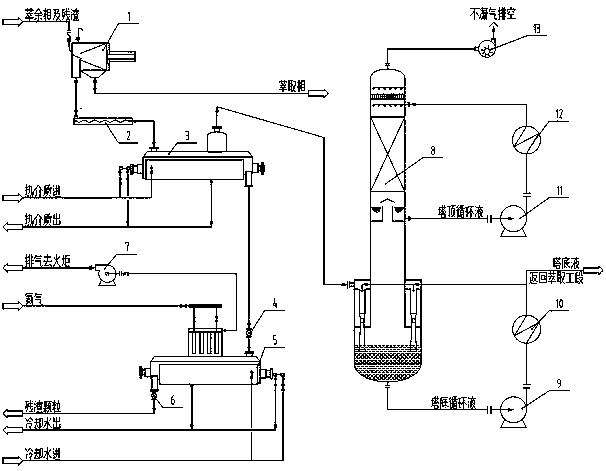

A recovery method of extractant in high-viscosity coal-based oil residue raffinate

ActiveCN108126369BLower evaporation temperatureReduce severitySolid solvent extractionSteam condensationBase oil

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION +1

Ultralow-temperature coal economizer for single-reheat unit

ActiveCN104990059AReduce coal consumption for power supplyReduce lossesCombustion technology mitigationFeed-water heatersSmokeEconomizer

The invention discloses an ultralow-temperature coal economizer for a single-reheat unit, particularly for a single-reheat coal-fired power generation unit. The ultralow-temperature coal economizer can replace low-pressure heaters to heat condensed water and is provided with condensation type heating surfaces which can recover vaporization latent heat of water vapor contained in part of discharged smoke. Low-temperature condensed water is used for absorbing nearly half of evaporation heat in the water vapor contained in the smoke; the temperature of the smoke is reduced to 50 DEG C; and electric energy generated additionally by a sixth-stage vapor extractor, a seventh-stage vapor extractor and an eighth-stage vapor extractor which are replaced can reduce the heat consumption of a generator set by 2.3%. Compared with the prior art, the ultralow-temperature coal economizer does not exclude partial vapor extraction or vapor extraction at a certain stage but completely replaces the low-pressure heater; water-side resistance of the ultralow-temperature coal economizer is far less than the sum of water-side resistance of four low-pressure heaters, and the shaft power of a condensate pump is reduced remarkably; the temperature of smoke which enters a desulfurizing tower is reduced remarkably, dosage of process water is reduced substantially, and the power consumption of an induced draft fan is reduced remarkably; and in a condensing and heat-releasing process, water vapor can also absorb PM2.5, SO3 and NOx in the smoke, and the micro-discharge of the coal-fired power generation unit is facilitated.

Owner:章礼道

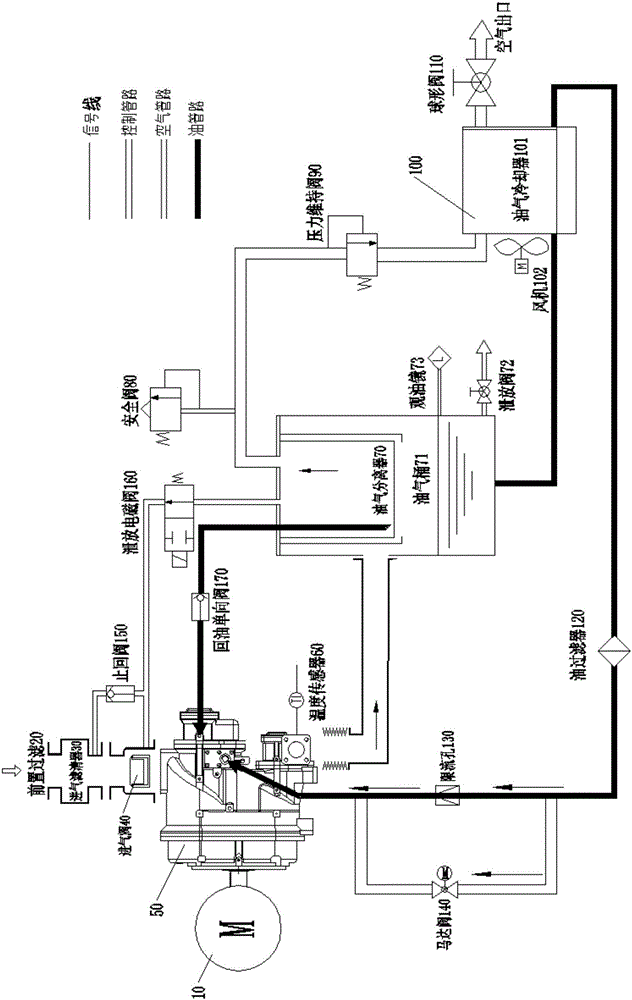

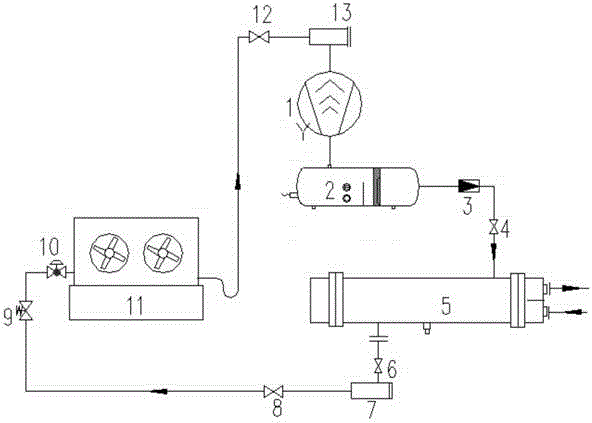

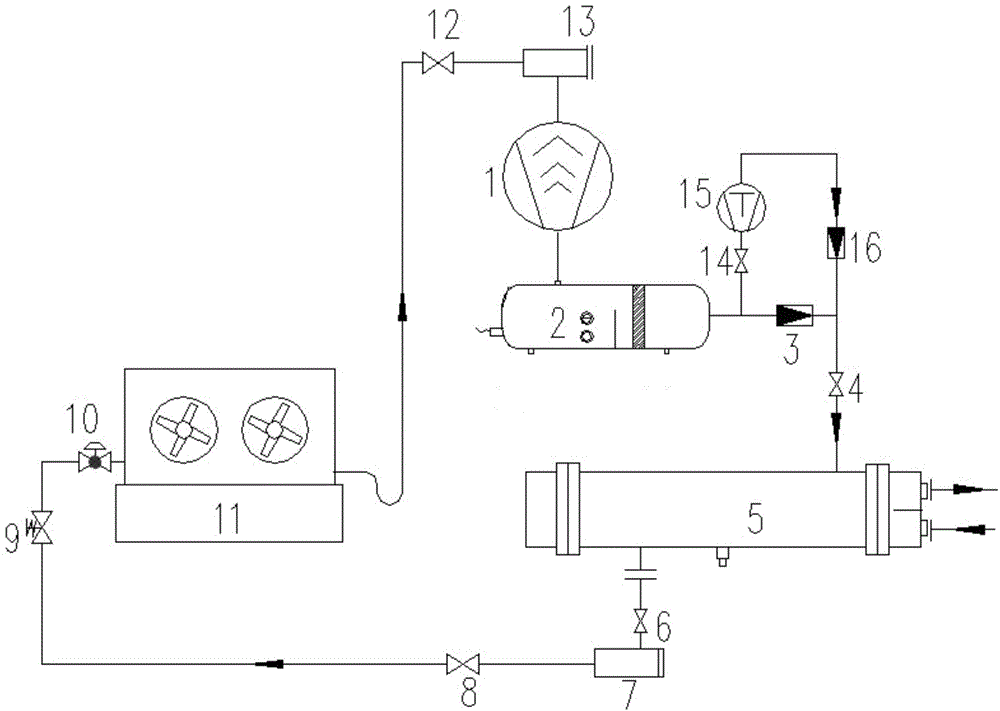

Air compressor with adjustable oil injection quantity

InactiveCN106121970AReduce fuel injectionReduce shaft powerPositive displacement pump componentsPositive-displacement liquid enginesAxial compressorGas cooler

The invention provides an air compressor with the adjustable oil injection quantity. The air compressor comprises a main body and an oil-gas cooler. The main body and the oil-gas cooler are connected through an oil pipeline. The air compressor further comprises a flow-limiting hole, a bypass pipe and a valve. The oil pipeline is provided with the flow-limiting hole. The bypass pipe is arranged at the flow-limiting hole. The valve is arranged on the bypass pipe. The air compressor has the advantages that the flow-limiting device is additionally arranged on a main oil injection pipeline, and the value is obtained through calculation according to the optimal state of the main body under various working conditions, powers, pressures and seasons and the minimum oil quantity capable of meeting gear, bearing and rotor lubricating requirements. Due to the fact that the bypass pipe is additionally arranged on one side of the flow-limiting hole and the bypass pipe is additionally provided with the valve, the caliber of the bypass pipe can be adjusted by controlling the valve, the oil injection quantity can be kept optimal all the time, and the air compressor efficiency achieves optimization.

Owner:SAZHEN COMPRESSOR SHANGHAI CO LTD

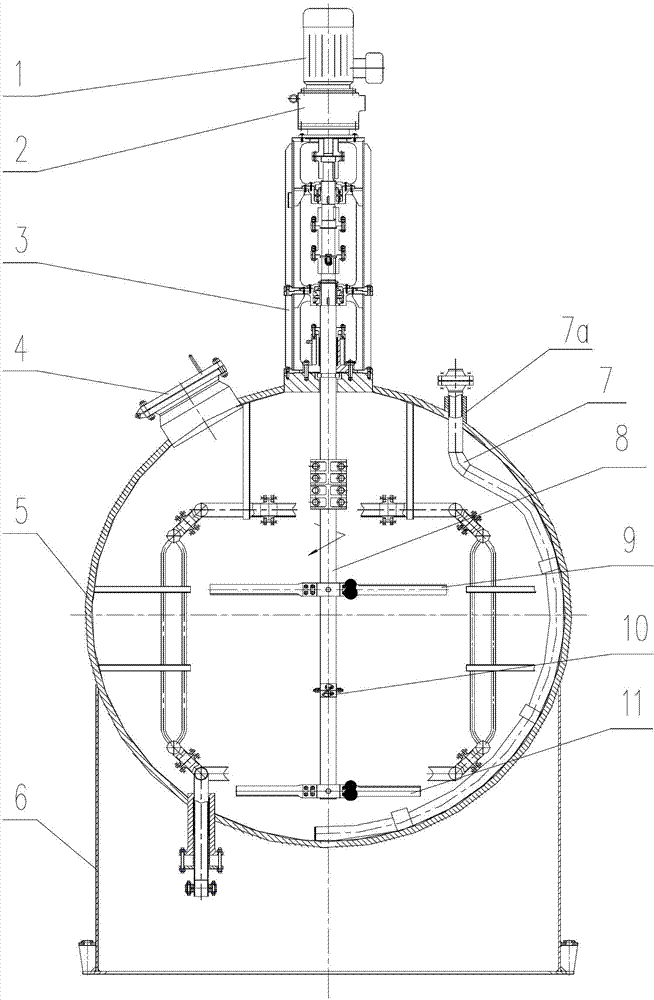

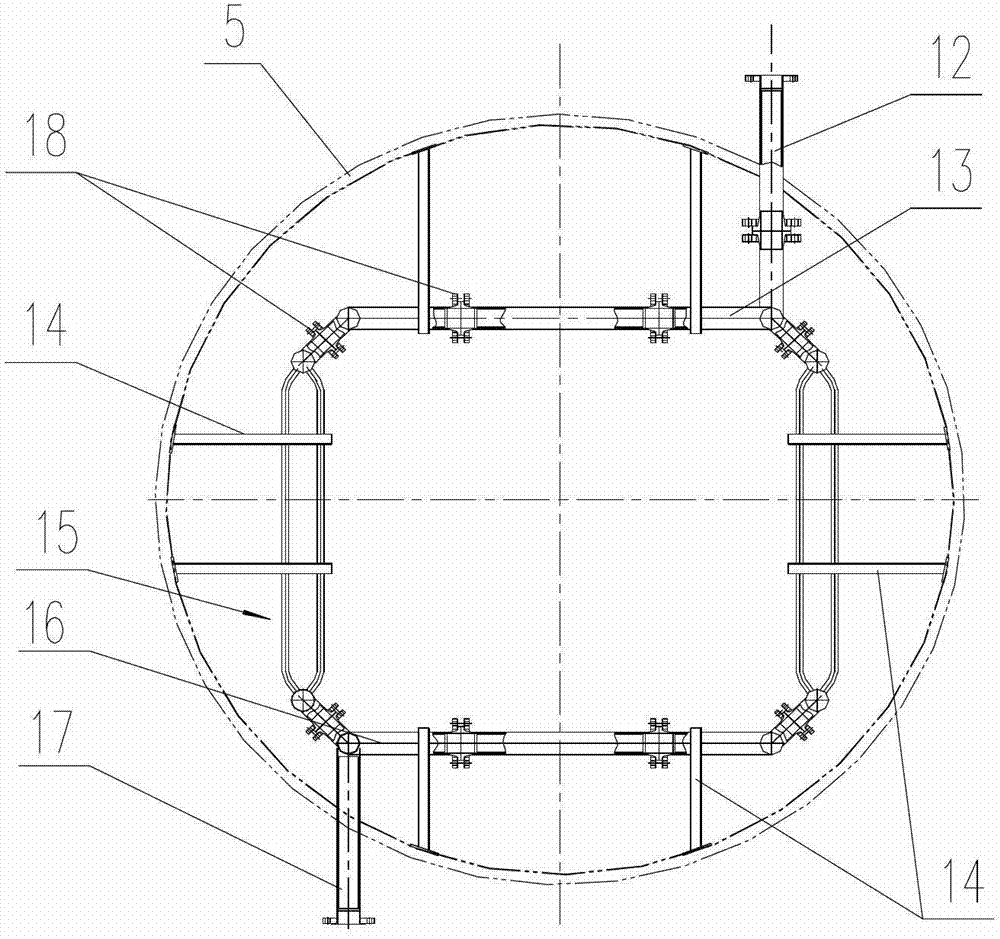

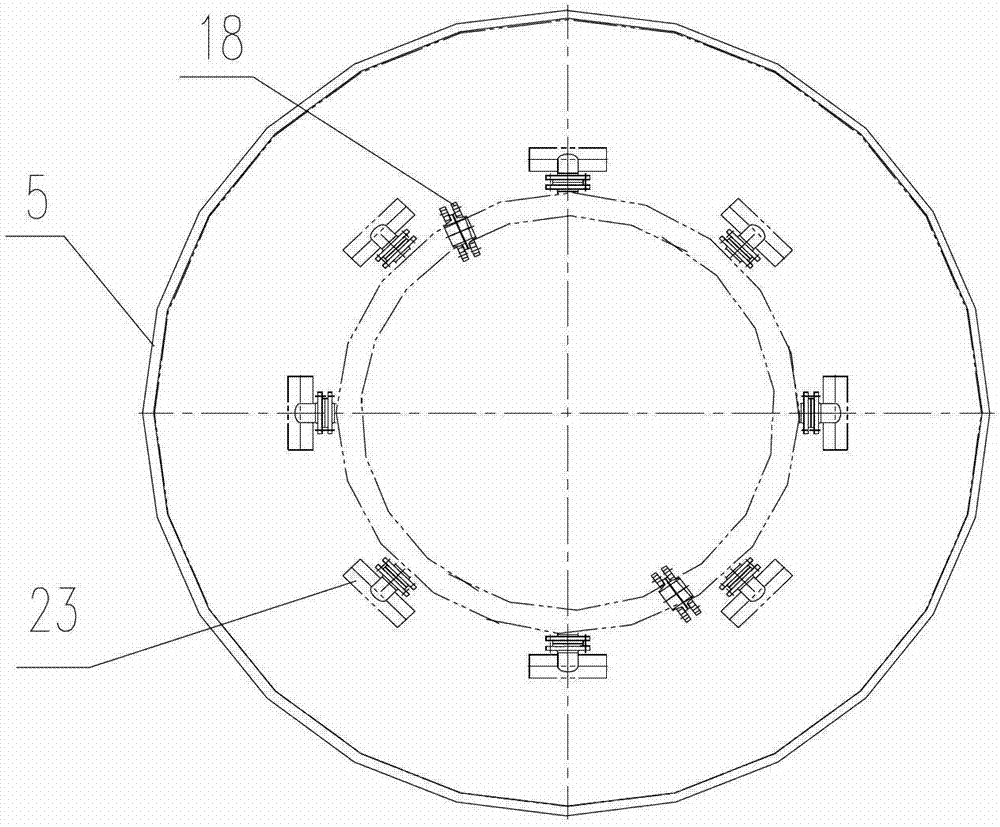

Large ammonification high pressure spherical stirring reaction kettle

ActiveCN102989372BUniform force distributionImprove the forceChemical/physical/physico-chemical stationary reactorsPressure vessels for chemical processReducerSpherical shaped

The invention relates to a large ammonification high pressure spherical stirring reaction kettle. A kettle body is welded by two spherical shaped kettles, the upper portion of the kettle body is provided with a feeding port, a discharging port, a safety relief device and an instrument control device, and the lower portion of the kettle body is provide with a skirt support. A stirring device is arranged at the upper end of the kettle body and matched with the kettle body in sealed mode, a motor, a reducer and the stirring device and sequentially connected, the lower portion of a stirring shaft penetrates into the kettle body, and a stirring device is fixed on the stirring shaft. A discharge pipe extends the a center position of the lower portion of the kettle body along the inner wall of the kettle body, a heat exchange device is arranged in the kettle body, the kettle body is made of an explosion double-layer composite plate material, an inner layer is made of stainless steel, an outer layer is made of carbon steel, the stirring shaft and the stirring device which are arranged in the kettle are made of stainless steel, and the heat exchange device is made of titaniumtim. The large ammonification high pressure spherical stirring reaction kettle has the advantages of guaranteeing energy conservation and consumption reduction, heat-transfer capability, homogeneity capability, antiseptic property and product quality of ammonification high pressure spherical stirring reaction kettle along with the enlargement of volume of the reaction kettle.

Owner:ANHUI BAYI CHEM IND

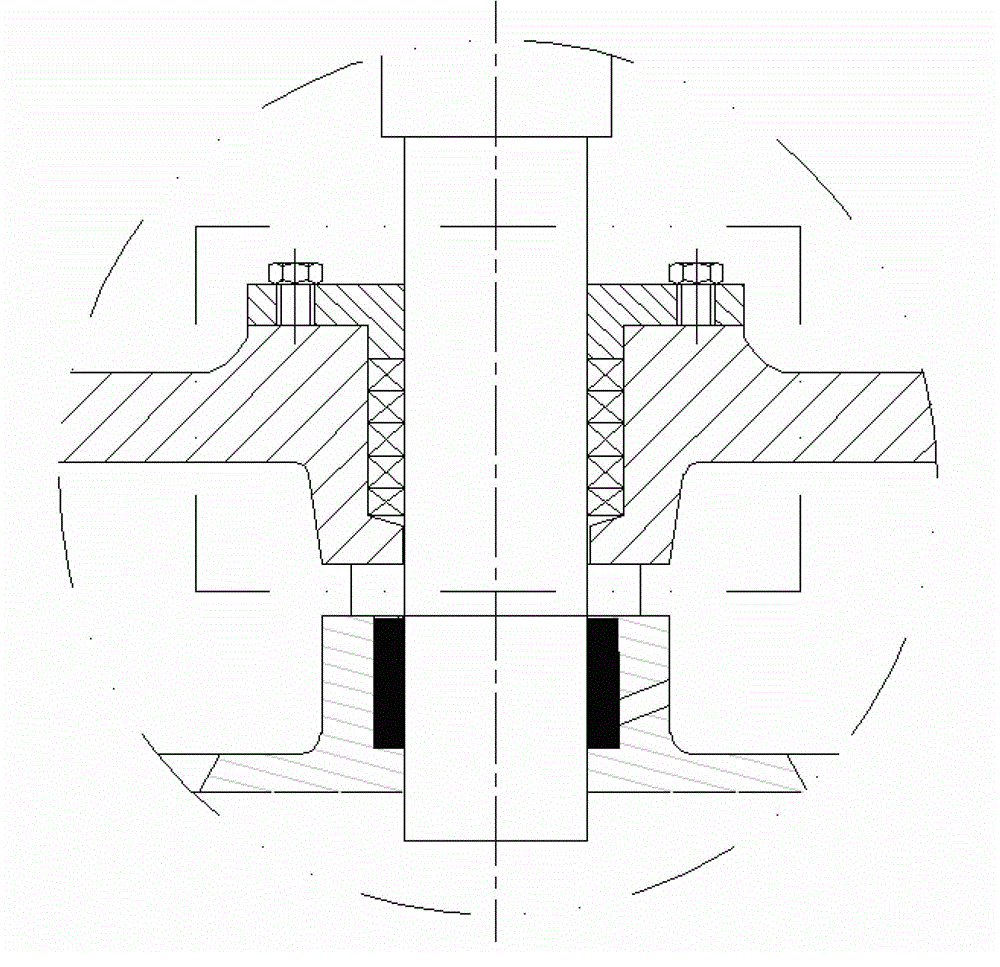

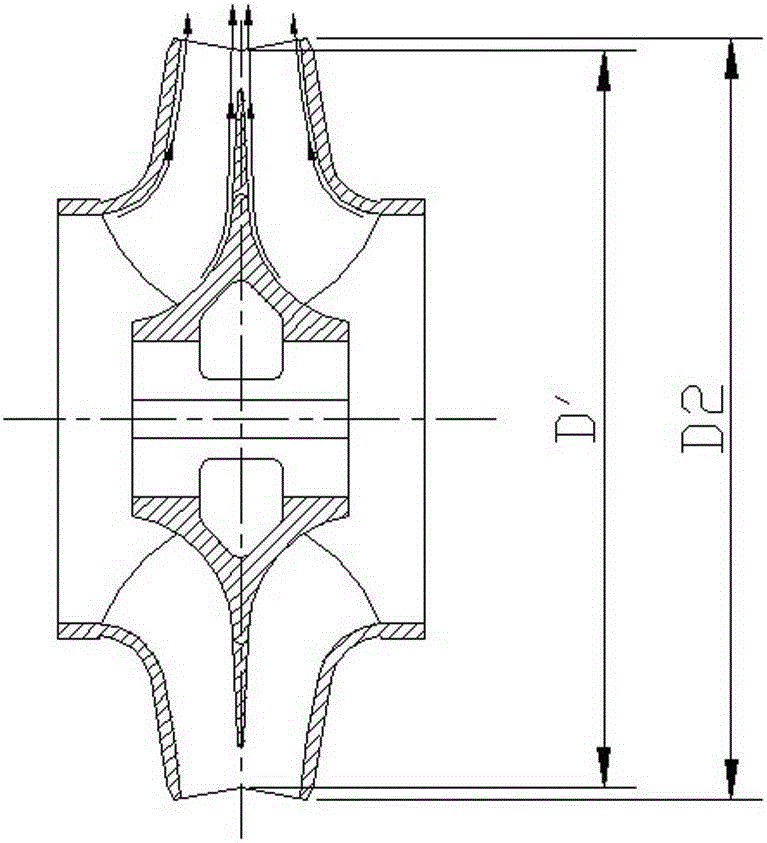

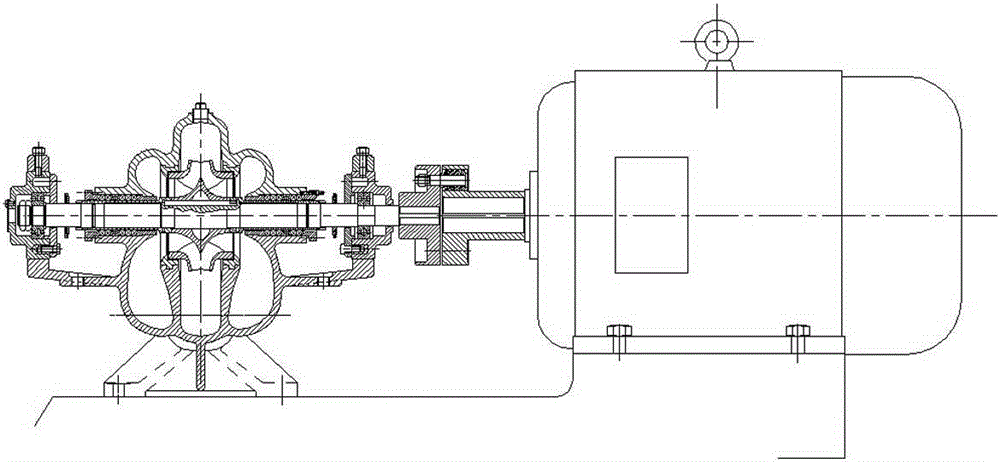

Double-suction centrifugal closed impeller outlet side concave structure

ActiveCN103711728BReduce length differenceEasy to movePump componentsPumpsEngineeringEnergy consumption

The invention discloses a concave structure of an outlet edge of a double-suction centrifugal closed impeller. An impeller inlet and blades are designed according to the structure of a common centrifugal pump impeller. All the outlet edges of the impeller are respectively provided with a concave structure. The outer diameter of an outlet of the impeller of the structure D2 is equal to 9.82*(ns / 100)-1 / 2(Q / n)1 / 3. The smallest diameter of a V-shaped groove in the middle D' is equal to (2-K')D2. The concave structures are arranged on all the outlet edges of the impeller, so that the length difference between an inner wall streamline of a runner and an outer wall streamline of the runner can be reduced, flowing of media in the runner can be directly improved, and vortexes are reduced orderly. Consequently, the energy consumption and noise of a centrifugal pump are reduced, and the shutout point lift and the shaft power of the double-suction centrifugal pump are reduced.

Owner:江苏振华海科装备科技股份有限公司

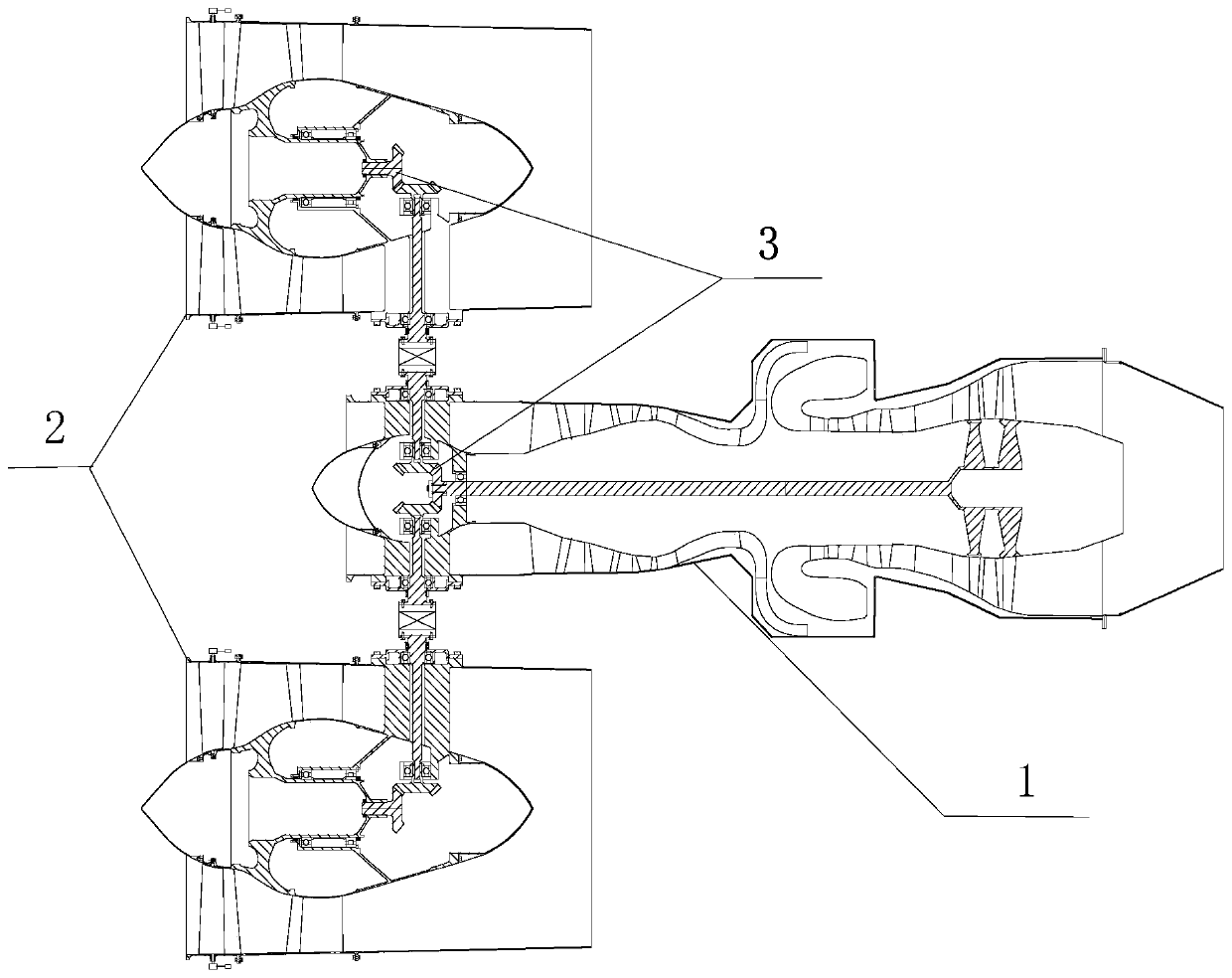

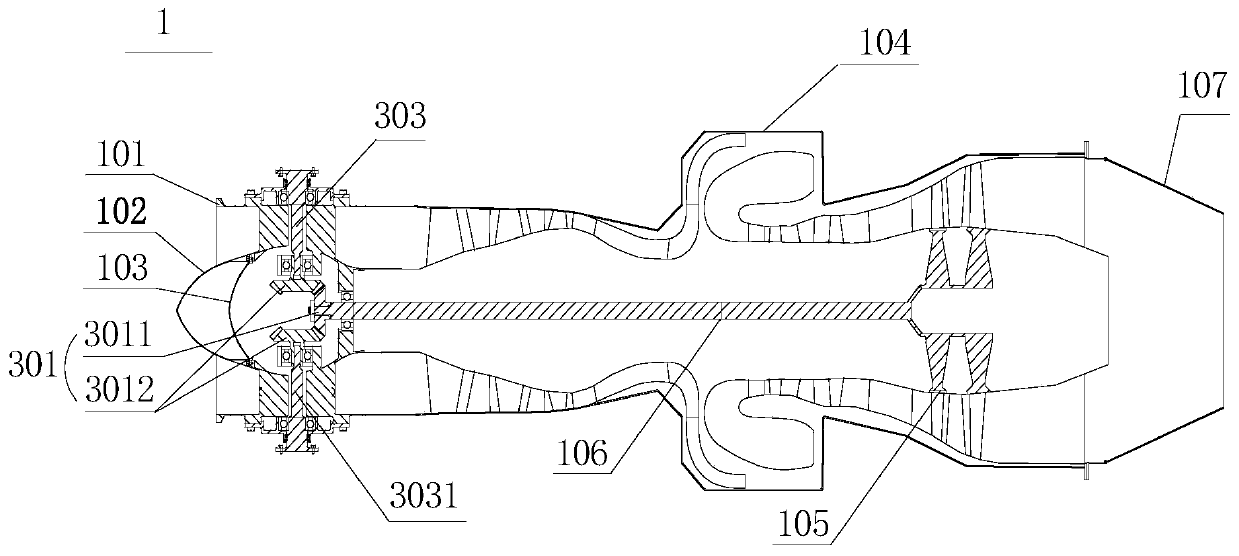

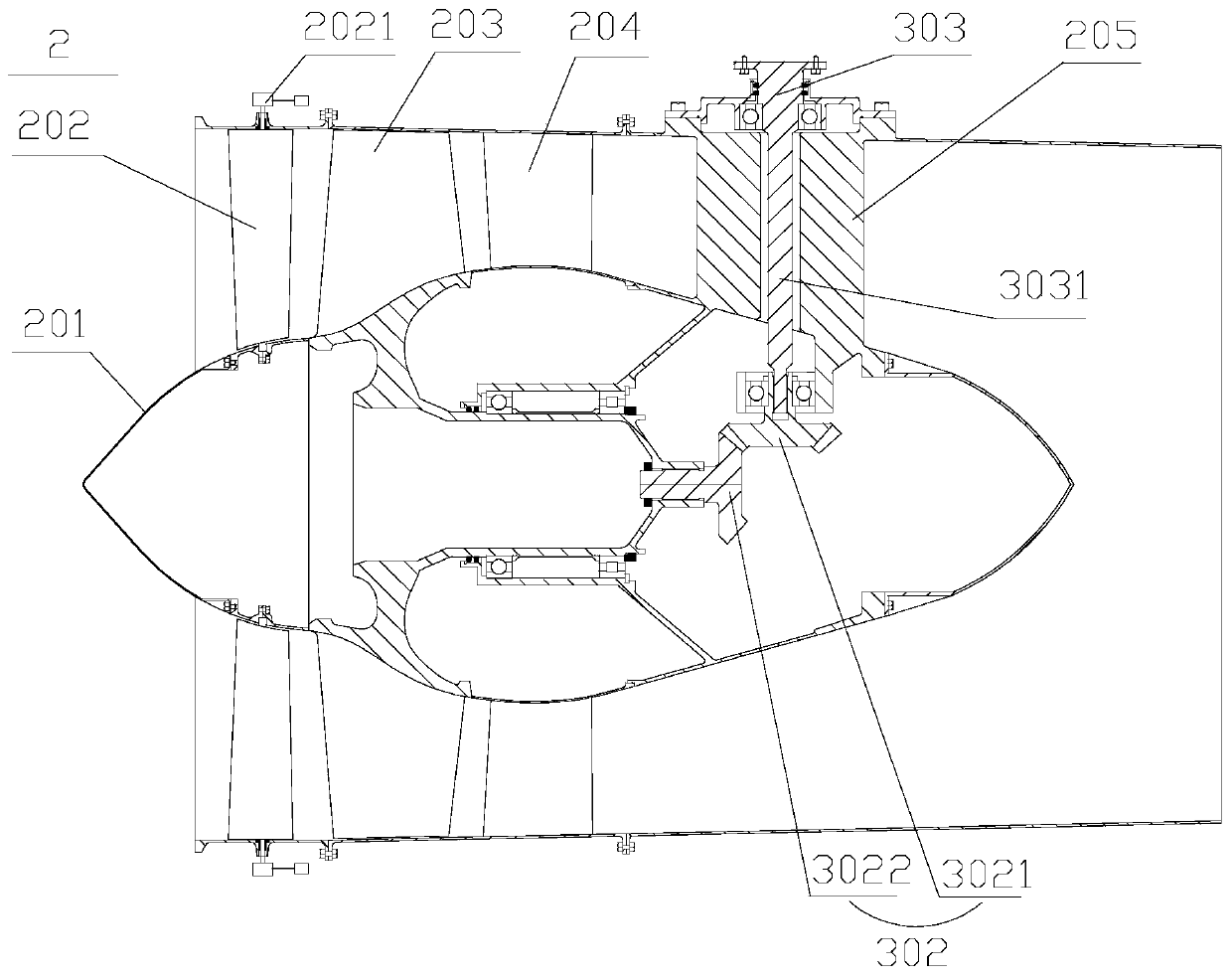

External parallel fan turbine engine and application thereof in field of flying wing aircrafts

InactiveCN110056451AIncrease bypass ratioLarge thrustGas turbine plantsJet propulsion plantsBypass ratioBevel gear

The invention discloses an external parallel fan turbine engine and application thereof in the field of flying wing aircrafts. The external parallel fan turbine engine comprises a main engine assembly, bypass fan assemblies and a bevel gear transmission assembly; the main engine assembly is a turboshaft engine / turboprop engine; the two or more sets of bypass fan assemblies are symmetrically and externally arranged on the two sides of the main engine assembly; a power turbine shaft of the main engine assembly and fan rotary shafts of the bypass fan assemblies are arranged in parallel; the transmission assembly comprises a main engine built-in transmission assembly and bypass fan built-in transmission assemblies; and the main engine assembly is connected with the bypass fan assemblies through the transmission assembly. Compared with conventional turbofan engines, the high bypass ratio design of the external parallel fan turbine engine can be achieved under a small engine height dimension, fuel consumption can be reduced, and the external parallel fan turbine engine is suitable for providing propulsion power for the flying wing aircrafts as blended wing bodies and is a power device with great potential for the new generation of passenger aircrafts with blended wing bodies.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

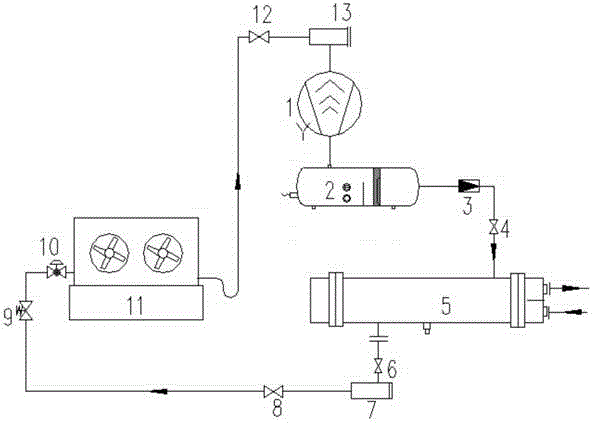

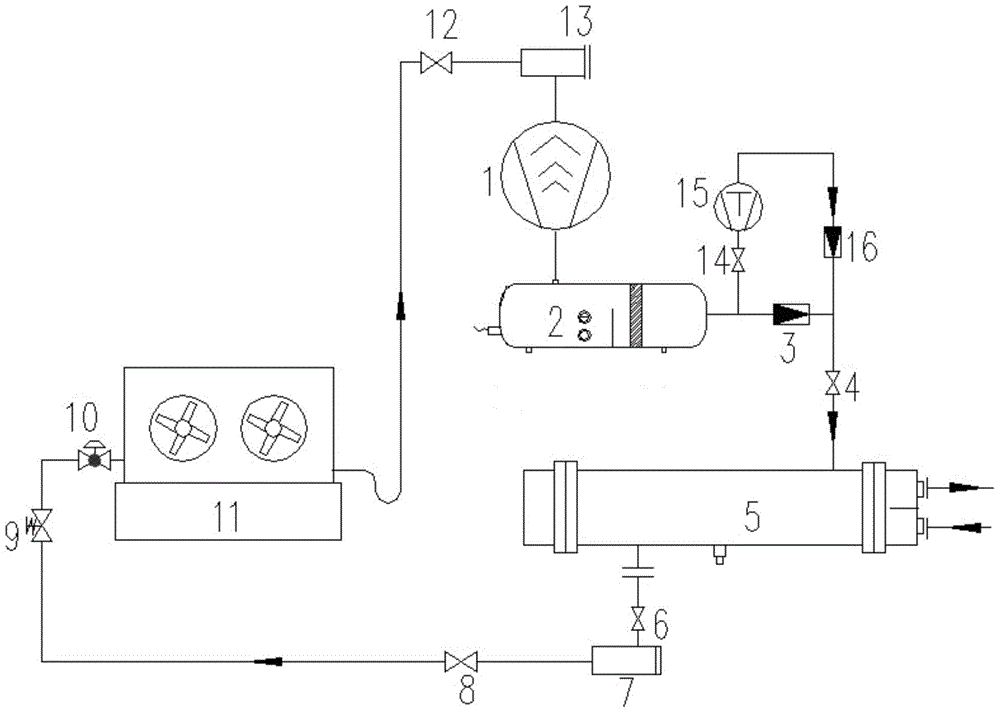

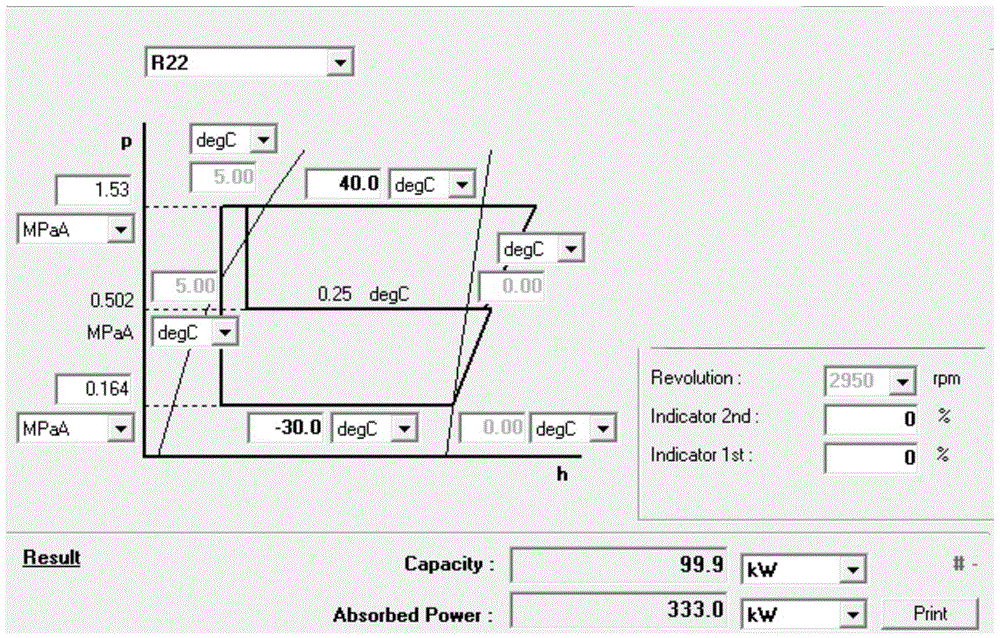

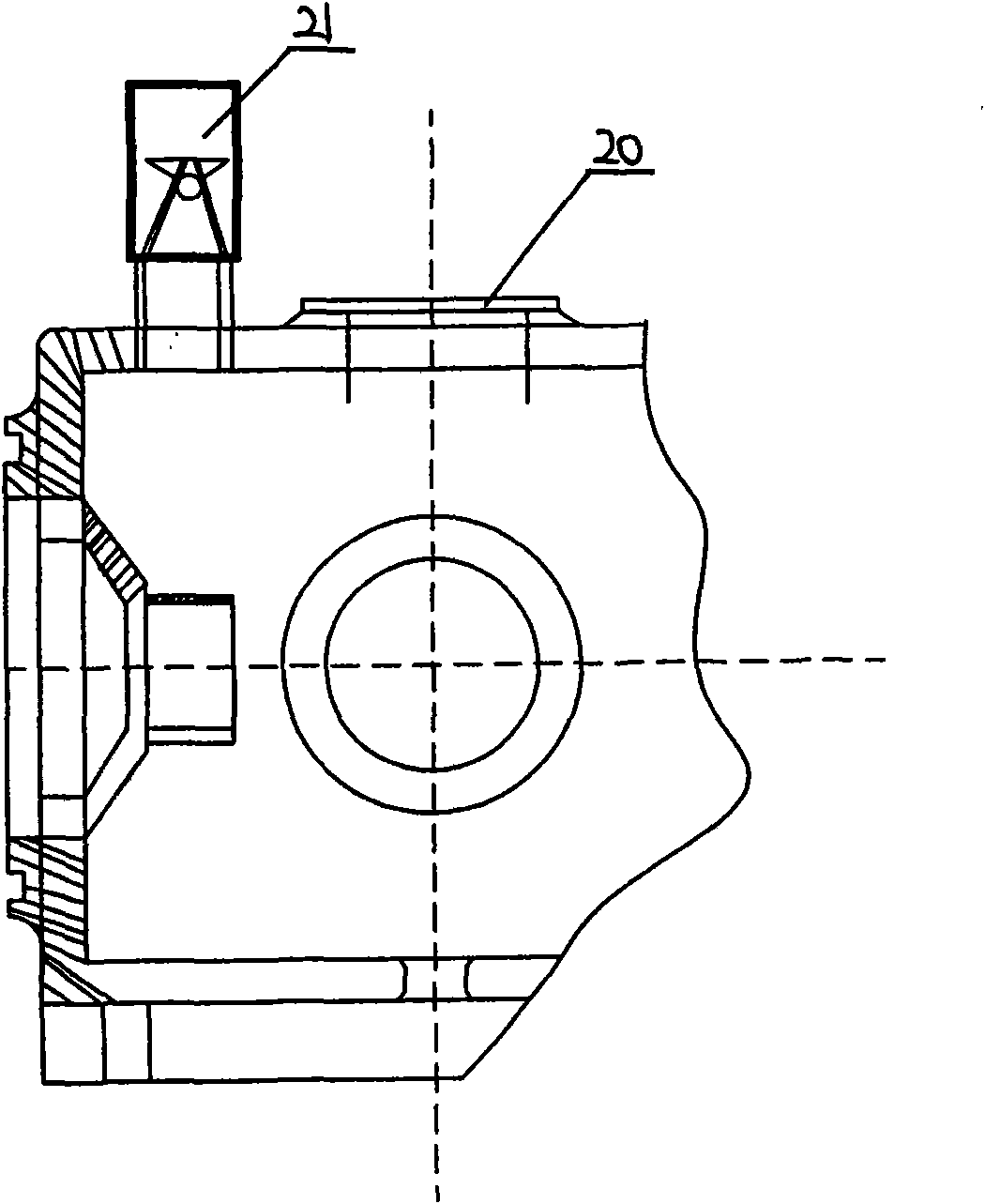

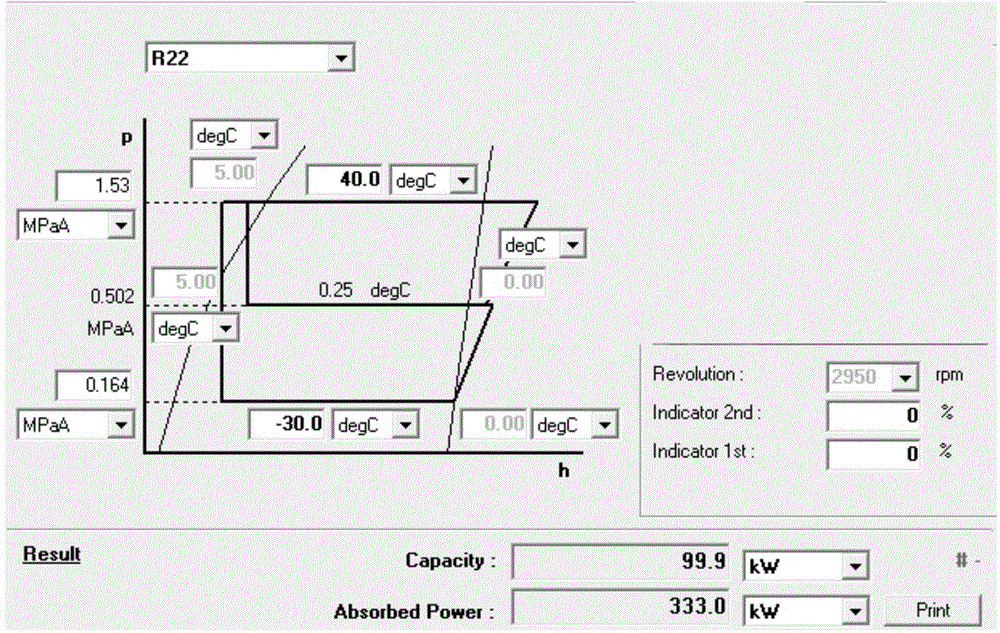

A method for starting a large-scale screw compressor and a large-scale screw compressor based on the method

The invention discloses a starting method of a large screw compressor and a large screw compressor based on the starting method; the starting method realizes the purpose of reducing the shaft power of the screw compressor starting by reducing the pressure in the oil separator; The reduction of the starting shaft power of the large screw compressor is realized by installing an auxiliary starting device between the inlet and outlet ends of the check valve a installed at the outlet of the oil separator, and the auxiliary starting device includes sequentially connected Shut-off valve e, auxiliary starter compressor and check valve b. It can be seen that the present invention solves the problem that the large-scale screw compressor is difficult to start.

Owner:SIFANG TECH GRP CO LTD

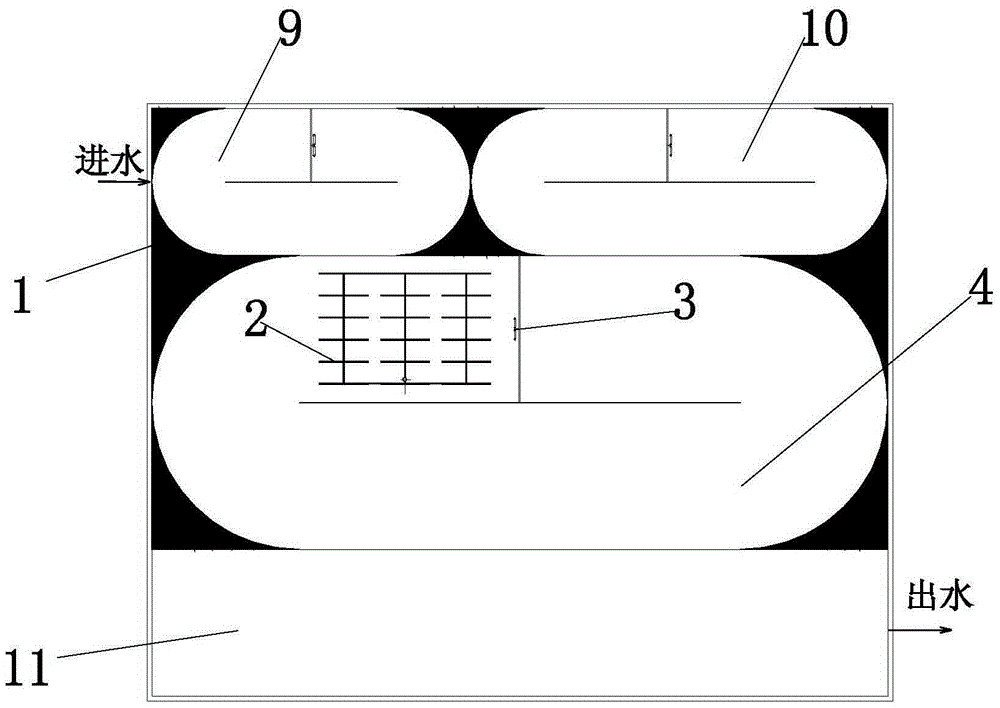

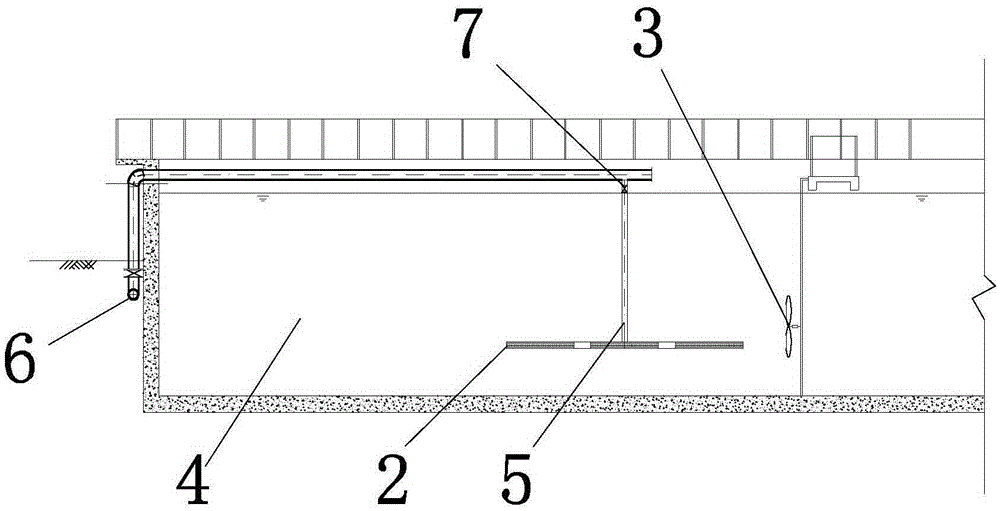

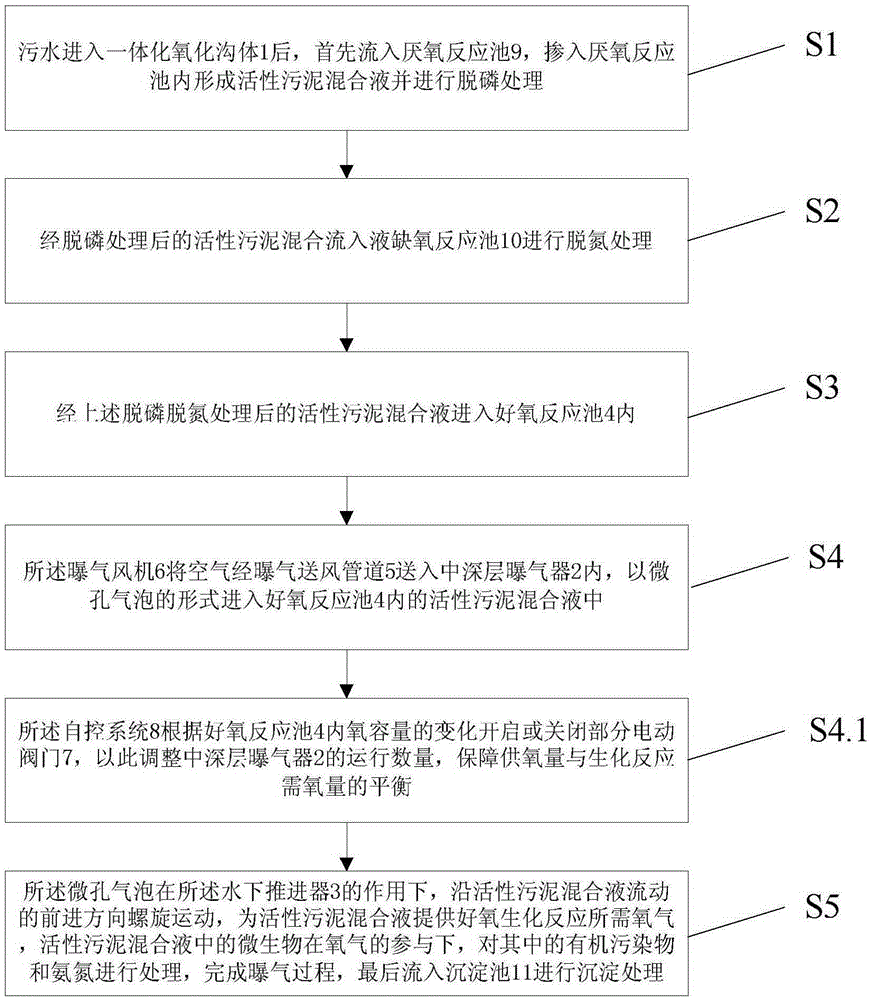

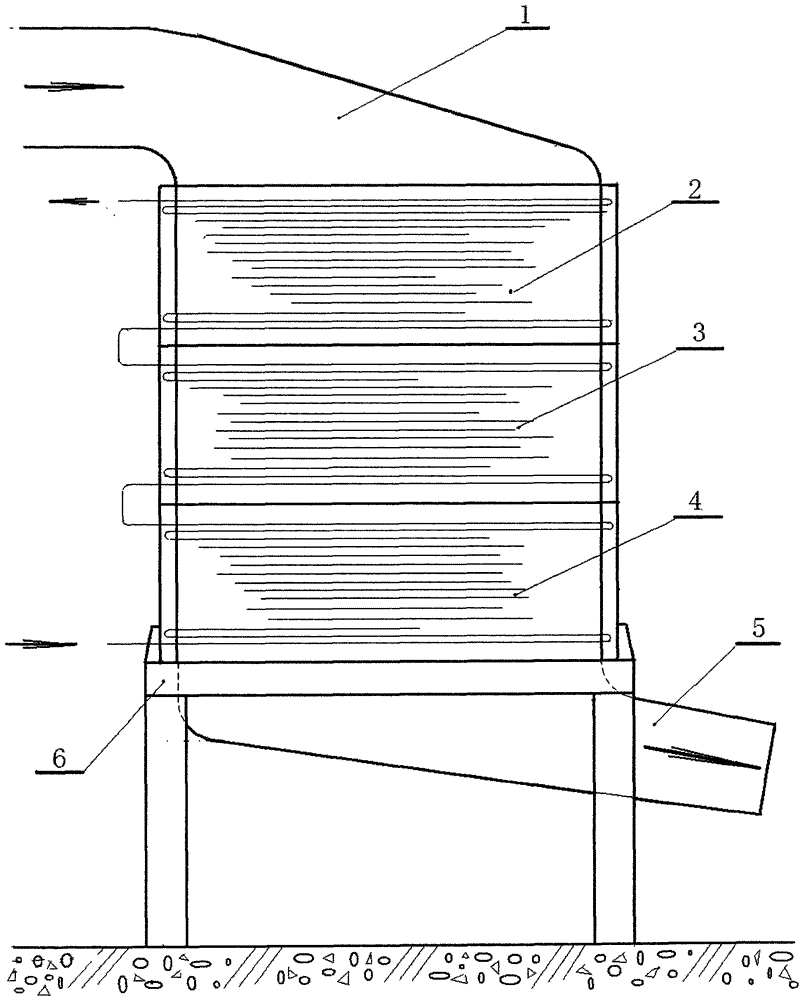

Device and method for deep aeration in integrated oxidation ditch

PendingCN105347488AImprove transfer efficiencyAdd depthTreatment with aerobic and anaerobic processesPropellerEnergy consumption

The invention discloses a device for deep aeration in an integrated oxidation ditch. The device comprises an integrated oxidation ditch body, a plurality of medium-deep aerators and an underwater propeller, wherein an anaerobic reaction tank, an anoxic reaction tank, an aerobic reaction tank and a sedimentation tank are sequentially arranged in the integrated oxidation ditch body in the sewage flowing direction; the medium-deep aerators are horizontally mounted at 1.3-1.7 m away from the bottom of the aerobic reaction tank; the medium-deep aerators are connected with an aeration blower by aeration air supply pipelines; the underwater propeller is vertically mounted in the aerobic reaction tank; the cable of the underwater propeller is connected with a power supply by a guide rod. The invention further provides a method for medium-deep aeration in the integrated oxidation ditch. The aeration time in the wastewater treatment process is prolonged, the flow patterns and the hybrid reaction states in the reaction tanks can be controlled more effectively, and energy consumption caused by aeration and flow pushing is greatly reduced; great convenience is provided for maintenance and replacement of underwater equipment, the service water depth is increased, and the building occupied area is reduced.

Owner:SOUTH CHINA UNIV OF TECH +2

Ultra-low temperature economizer for primary reheat unit

ActiveCN104990059BReduce heat consumptionSignificant thermoeconomic benefitsCombustion technology mitigationFeed-water heatersWater vaporEvaporation

The invention discloses an ultralow-temperature coal economizer for a single-reheat unit, particularly for a single-reheat coal-fired power generation unit. The ultralow-temperature coal economizer can replace low-pressure heaters to heat condensed water and is provided with condensation type heating surfaces which can recover vaporization latent heat of water vapor contained in part of discharged smoke. Low-temperature condensed water is used for absorbing nearly half of evaporation heat in the water vapor contained in the smoke; the temperature of the smoke is reduced to 50 DEG C; and electric energy generated additionally by a sixth-stage vapor extractor, a seventh-stage vapor extractor and an eighth-stage vapor extractor which are replaced can reduce the heat consumption of a generator set by 2.3%. Compared with the prior art, the ultralow-temperature coal economizer does not exclude partial vapor extraction or vapor extraction at a certain stage but completely replaces the low-pressure heater; water-side resistance of the ultralow-temperature coal economizer is far less than the sum of water-side resistance of four low-pressure heaters, and the shaft power of a condensate pump is reduced remarkably; the temperature of smoke which enters a desulfurizing tower is reduced remarkably, dosage of process water is reduced substantially, and the power consumption of an induced draft fan is reduced remarkably; and in a condensing and heat-releasing process, water vapor can also absorb PM2.5, SO3 and NOx in the smoke, and the micro-discharge of the coal-fired power generation unit is facilitated.

Owner:章礼道

Method for heating primary air with heat of flue gas bypass of tri-sectional air preheater

PendingCN107655026AReduce air leakage rateReduce resistanceCombustion processIndirect carbon-dioxide mitigationAir preheaterProcess engineering

The invention discloses a method for heating primary air with heat of a flue gas bypass of a tri-sectional air preheater. The method comprises the steps as follows: hot boiler flue gas enters a main hot flue gas path and the hot flue gas bypass through a hot boiler flue gas inlet respectively; the hot boiler flue gas enters a shell-and-tube primary air heat exchanger through the flue gas bypass toheat cold primary air entering the shell-and-tube primary air heat exchanger through a cold primary air inlet, the heated cold primary air becomes hot primary air, and the hot primary air flows out of a hot primary air outlet; the hot boiler flue gas enters a flue gas bin of the tri-sectional air preheater through the main hot flue gas path to heat cold secondary air; the cold secondary air enters a primary air bin and a secondary air bin of the tri-sectional air preheater through a cold secondary air inlet respectively for heating, and the heated cold secondary air flows out of a hot secondary air outlet. With the method, the air leakage rate of the tri-sectional air preheater is reduced, the exhaust gas temperature is reduced, then the boiler efficiency can be improved, and the coal consumption is reduced.

Owner:北京慧峰仁和科技股份有限公司

Oil-free pendulum type air compressor

InactiveCN101566143AReduce heat conduction areaExtended service lifePositive displacement pump componentsPositive-displacement liquid enginesAir filterRolling-element bearing

The invention relates to an oil-free pendulum type air compressor, which prolongs the working time, reduces the temperature of lubricating oil for a transmission mechanism by 20 DEG C, changes an air inlet flue from a single cavity to double cavities, reduces pulse action, and greatly improves the service life of components. The oil-free pendulum type air compressor comprises a body shell, a crank case, a connecting rod, a rotor, a cylinder, a valve, a sensor and a belt pulley. A crank shaft is arranged on the body shell; the connecting rod is arranged on the crank shaft; the other end of the connecting rod is arranged at one end of a shaft of the rotor; the rotor is arranged in the cylinder; and one end of the crank shaft is provided with the belt pulley, and the other end of the crank shaft is provided with sensor shaft of a sensor motor. The oil-free pendulum type air compressor is characterized in that the connecting rod is arranged on the crank shaft through a pin shaft; a rolling bearing is arranged between the connecting rod and the pin shaft; a plurality of concave parts are evenly distributed on the connected end surface of a connector between the cylinder and the body shell; and the cylinder and the body shell are reserved with an air inlet respectively, and the front end of the air inlet is provided with an air filter. The oil-free pendulum type air compressor is applicable to a cement bulk truck, and also can be used for other devices.

Owner:邢汝福

Starting method of large-scale screw compressor and large-scale screw compressor based on starting method

The invention discloses a starting method of a large-scale screw compressor and the large-scale screw compressor based on the starting method. According to the starting method disclosed by the invention, the purpose of reducing the starting shaft power of the large-scale screw compressor is realized through reducing the pressure in an oil separator; the reducing of the starting shaft power of the large-scale screw compressor is realized through arranging an auxiliary starting device between an inlet end and an outlet end of a check valve a which is arranged in an outlet of the oil separator, and the auxiliary starting device comprises a stop valve e, an auxiliary starting compressor and a check valve b which are sequentially connected. According to starting method and the large-scale screw compressor, disclosed by the invention, the problem that the large-scale screw compressor is difficult to start is solved.

Owner:SIFANG TECH GRP CO LTD

Low-pressure steam generation system of scalding basin

The invention discloses a low-pressure steam generating system for a scalding pool, which includes a scalding pool, a blower and a low-pressure steam generator. The water inlet pipe for providing hot water; the low pressure steam generator is also connected with a water outlet pipe; the blower is arranged at the front end of the low pressure steam generator, or between the low pressure steam generator and the scalding pool, or is arranged in the gas inside the low pressure steam generator. on the way. By changing the stirring and replenishing method of the scalding tank, the consumption of heating steam is reduced, and the production cost and operation cost are reduced.

Owner:李永堂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com