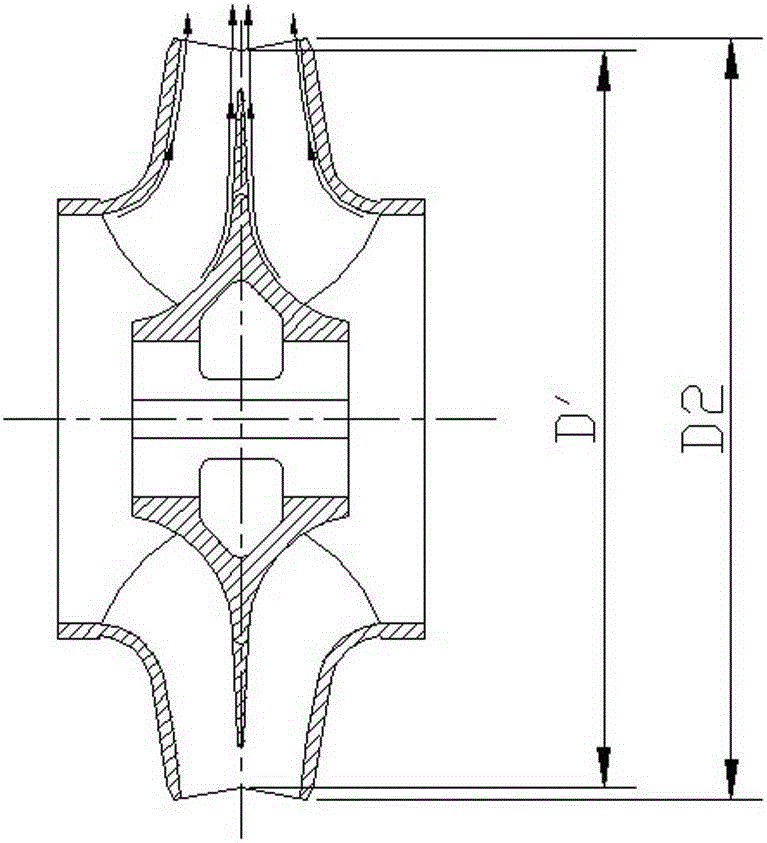

Double-suction centrifugal closed impeller outlet side concave structure

A centrifugally closed, centrifugal pump impeller technology, used in non-variable volume pumps, components of pumping devices for elastic fluids, machines/engines, etc. Large difference in length and other problems, to achieve the effect of improving flow, reducing streamline length difference, and reducing vortex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

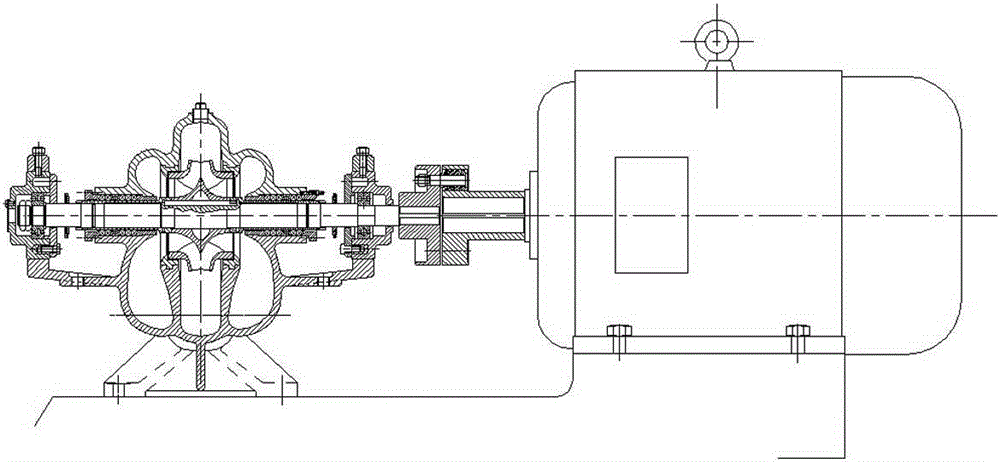

[0019] This embodiment is matched with figure 2 In the double-suction centrifugal pump shown, the rated flow of the pump is Q=1080m 3 / h (single suction 540m 3 / h), than the number of revolutions n s =101.5, rated speed n=1450r / min, V-groove coefficient K' on the outlet side of the impeller is smaller than the number of revolutions, K'=1.03. Calculate D according to the present invention 2 =9.82 (n s / 100) -1 / 2 (Q / n) 1 / 3 =9.82 (101.5 / 100) -1 / 2 (540 / 1450) 1 / 3 =0.442, D'=(2-K')D 2 =(2-1.03)×0.442=0.429. The present invention provides a concave structure at the outlet of the impeller, which can reduce the length difference between the inner and outer walls of the flow channel, directly improve the flow of the medium in the flow channel, orderly flow reduces the vortex, thereby reducing the energy loss and noise of the centrifugal pump, and at the same time It also reduces the lift and shaft power of the double-suction centrifugal pump at the dead point.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com