Soft package button cell, manufacturing method thereof and electronic equipment

A technology of a button battery and a manufacturing method, which is applied to the manufacture of electrolyte batteries, lithium batteries, battery pack components, etc., can solve problems such as the occurrence of noise floor and reduce product quality, and achieve the effect of eliminating interference magnetic fields and improving the noise floor phenomenon of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

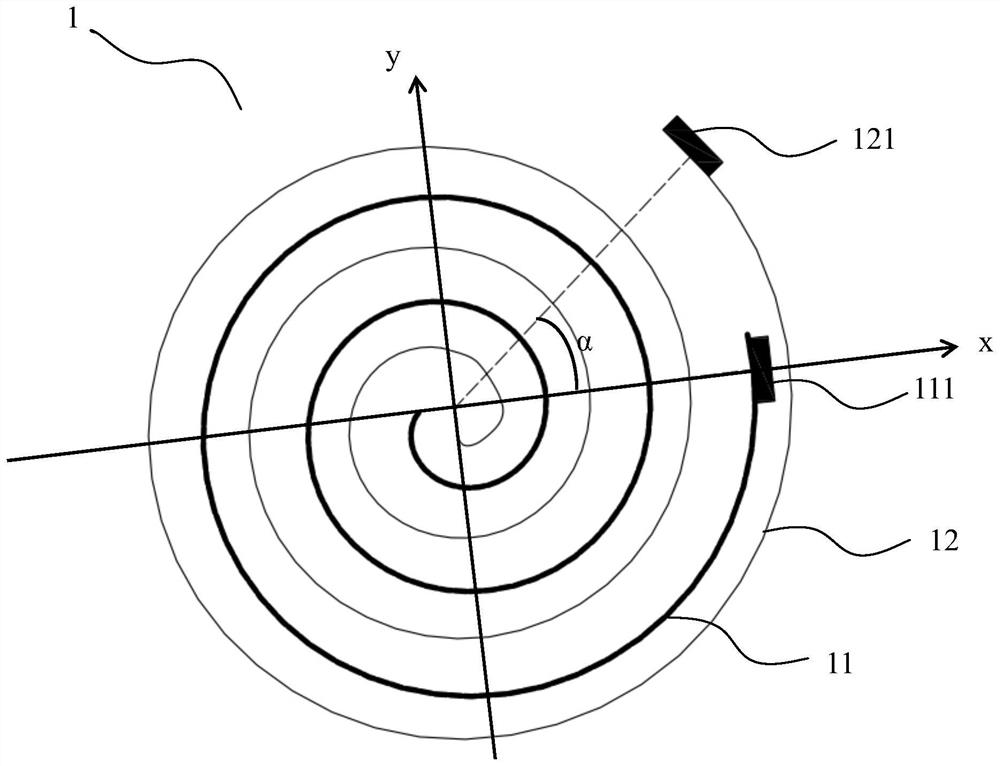

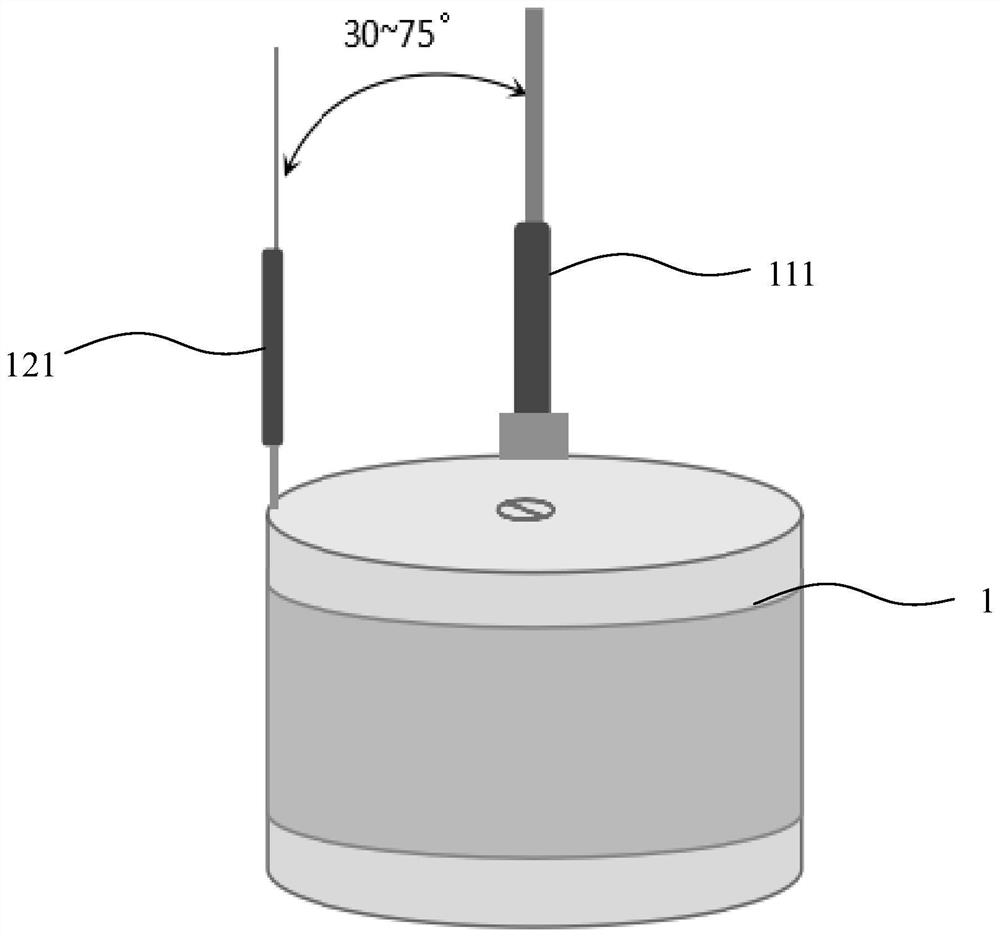

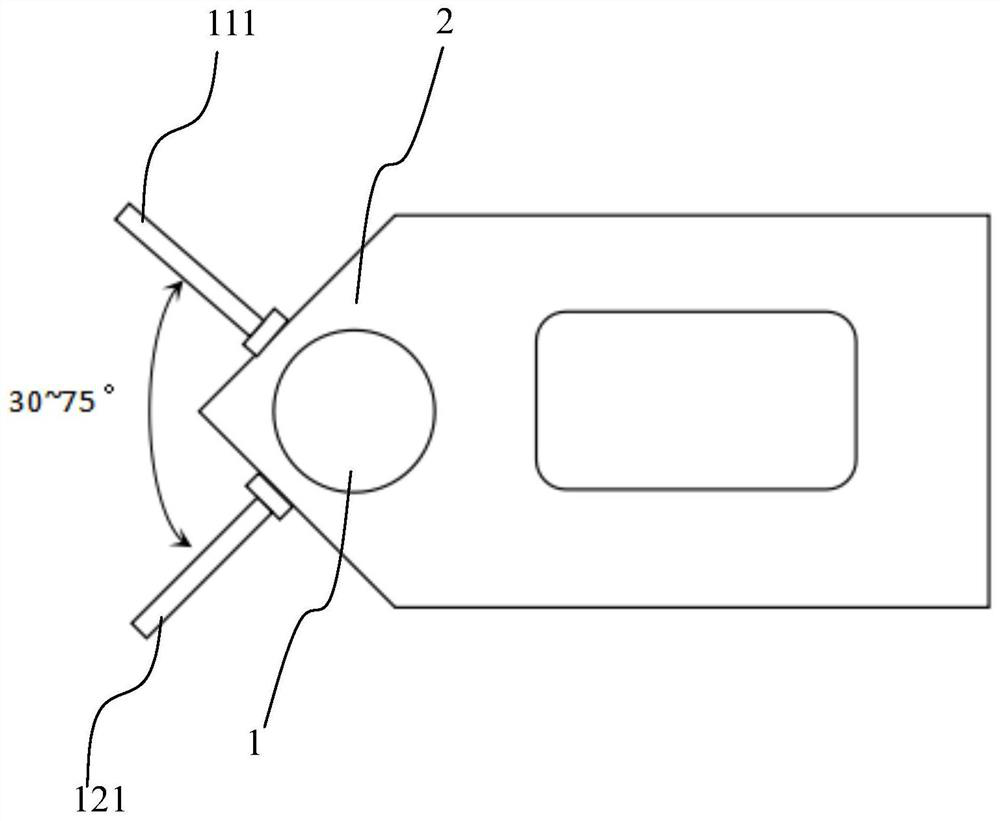

[0066] refer to figure 1 As shown, this embodiment is used to illustrate the soft pack button battery disclosed in the present invention and its manufacturing method, including the following steps:

[0067] Step S1: Take the positive electrode sheet and the negative electrode sheet, weld the positive electrode ear on the second end of the positive electrode sheet, and weld the negative electrode ear on the second end of the negative electrode sheet, and stack them in order according to the diaphragm, positive electrode sheet, diaphragm, and negative electrode sheet, starting from the second end of the negative electrode sheet. One end is wound into a cylindrical winding core toward the second end, wherein the first end of the negative electrode sheet is located inside the first end of the positive electrode sheet, and the second end of the negative electrode sheet is located outside the second end of the positive electrode sheet, with the positive tab The line connecting the c...

Embodiment 2

[0072] This embodiment is used to illustrate the soft pack button battery disclosed in the present invention and its manufacturing method, including most of the operations of Embodiment 1, the only difference is that the angle α between the first reference line and the second reference line is 45°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com