Fuel jetting valve dispatching structure of V-type two-cylinder engine

A fuel injection valve and engine technology, applied in fuel injection devices, low-pressure fuel injection, low-pressure fuel injection, etc., can solve problems such as not meeting the intake efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

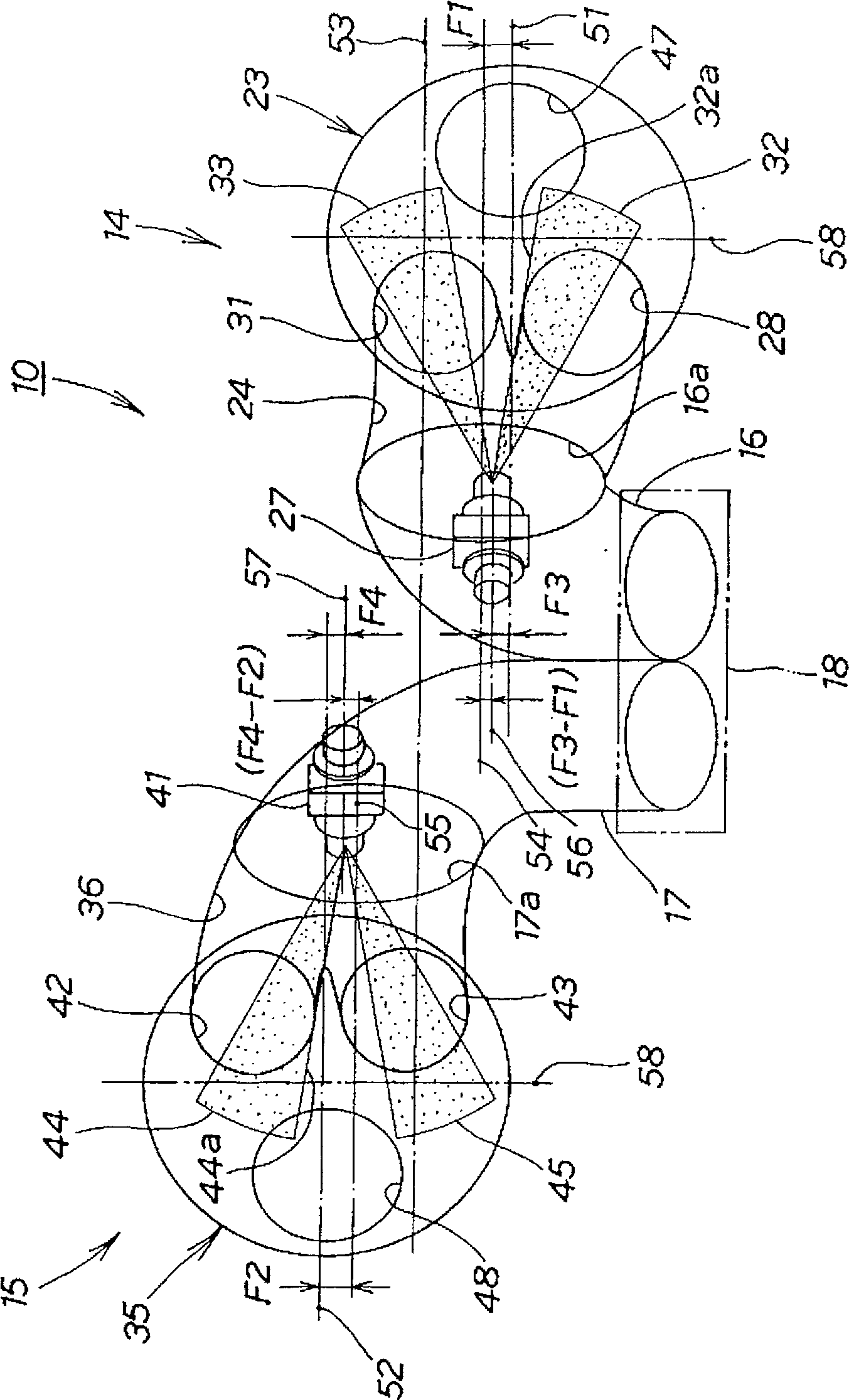

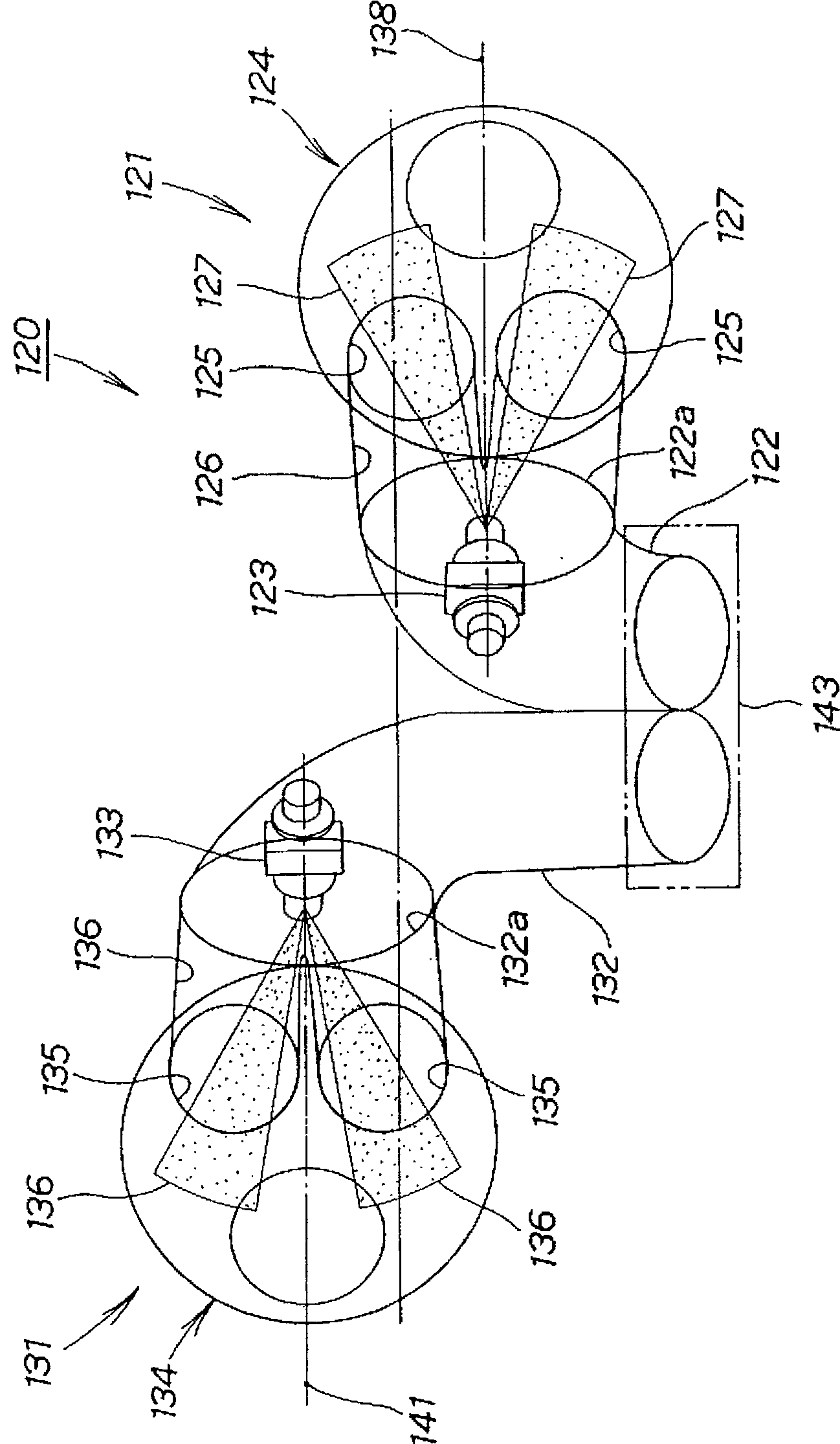

[0016] Embodiments of the present invention will be described below with reference to the drawings. The drawings are viewed in the direction of the markings.

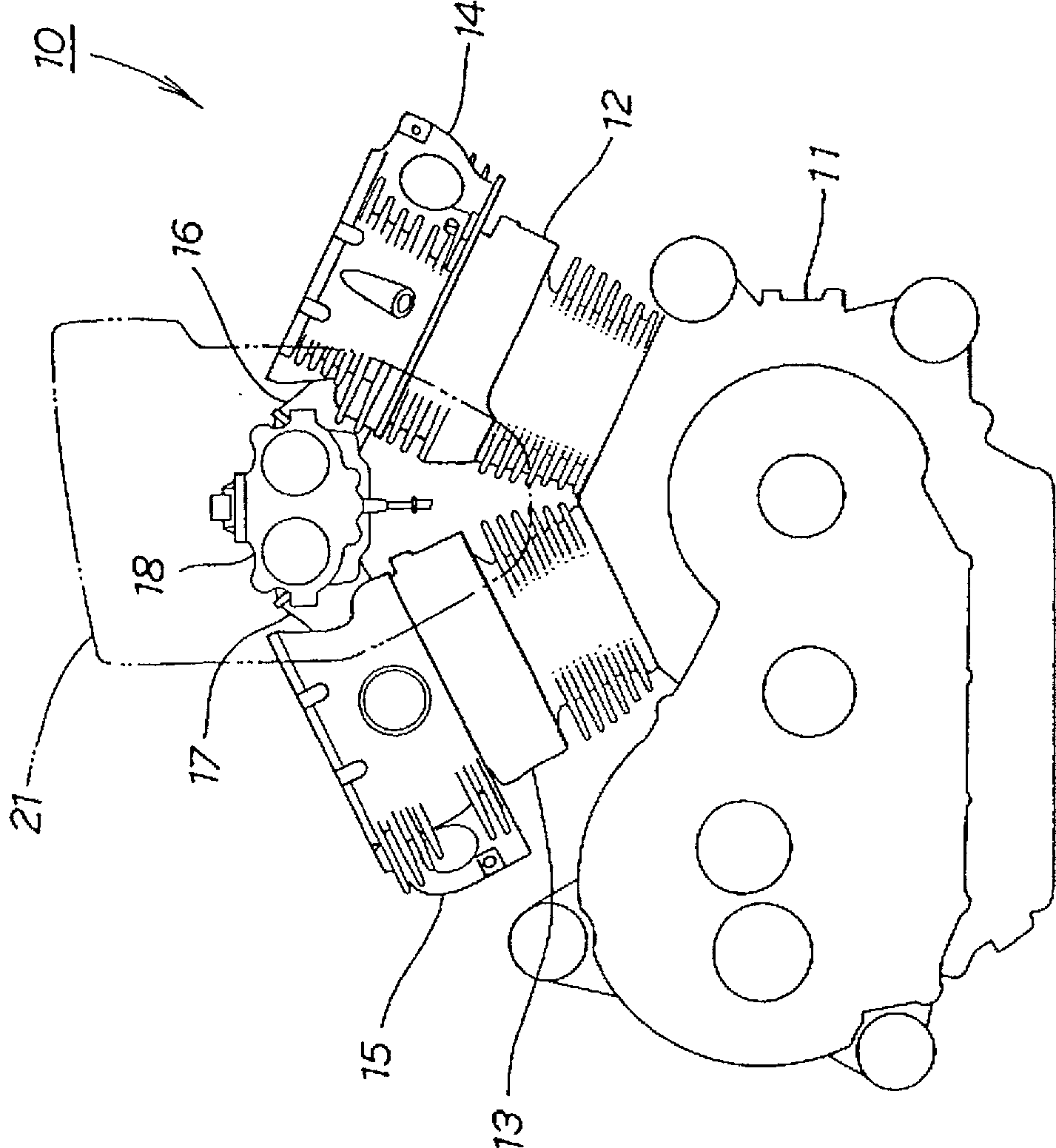

[0017] figure 1 It is a side view of the engine adopting the structure of the fuel injection valve of the present invention. The engine 10 is a V-type 2-cylinder engine. A first cylinder block 12 and a second cylinder block 13 are installed on the top of the crankcase 11, and a first cylinder head 14 is installed on the top of these first and second cylinder blocks 12 and 13, respectively. and the second cylinder head 15, on these first and second cylinder heads 14 and 15, a throttle body 18 for 2 cylinders is installed through the first and second intake manifolds 16 and 17, and the throttle body 18 Air filter 21 is installed on it.

[0018] The engine 10 is a V-type engine whose cylinder pinch angle is less than 90°. Since it is difficult to arrange the throttle body 18 between the first and second cylinder heads ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com