Coal dressing separator

A separation device and coal preparation technology, applied in swirling devices, devices whose axial directions of swirling can be reversed, etc., can solve the problem of increasing the manufacturing cost and maintenance cost of the device, the damage of the intermediate wear-resistant pipeline, and the price of the wear-resistant pipeline. Expensive and other problems, to achieve the effect of not easy leakage accident, good air tightness, and obvious energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

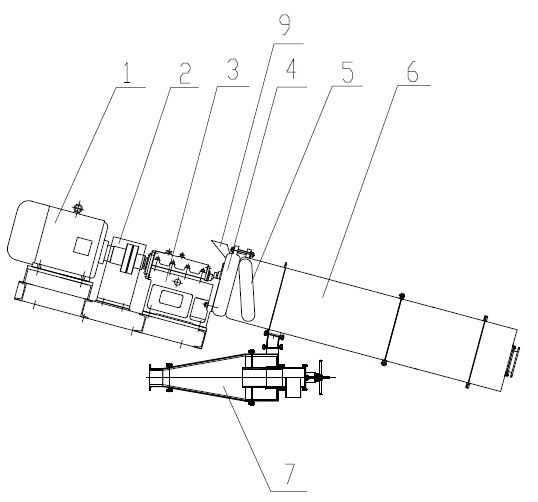

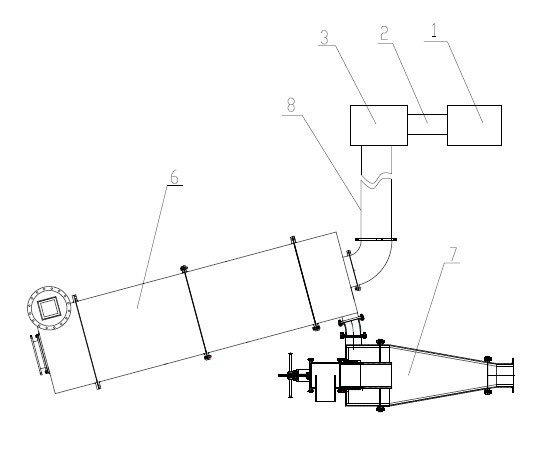

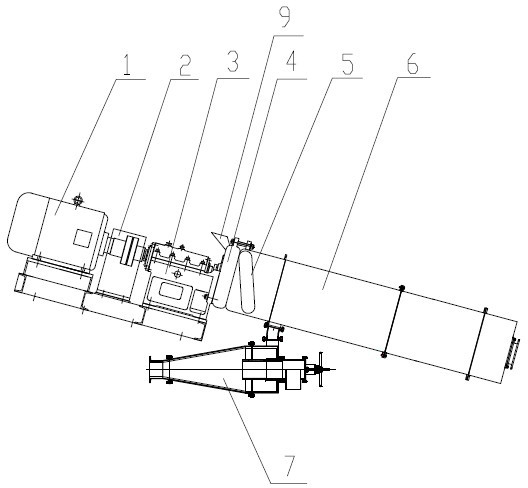

[0011] Such as figure 1 As shown, a coal preparation separation device includes a motor 1, a cyclone pump 3, a first-stage cyclone 6 and a second-stage cyclone 7; the motor 1 is connected to the cyclone pump 3 through a coupling 2. The cyclone pump The pump head 4 of 3 is fixed to the end of a cyclone section 6 by bolts. The casing of the cyclone pump is integrated with a cyclone section. The discharge port on the pump head 4 directly enters the cyclone section 6 and the pipe The exit direction of the path 5 is parallel to the tangential direction of a section of the cyclone body.

[0012] Such as figure 1 As shown, the two-stage cyclone 7 includes a first cylindrical section connected with the one-stage cyclone, a first conical section connected with the first cylindrical section, and a second cylindrical section connected with the first conical section, The diameter of the first cylindrical section is greater than the diameter of the second cylindrical section.

[0013] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com