Impeller and slurry pump

A technology for slurry pumps and impellers, applied in pumps, pump devices, pump components, etc., can solve the problems that the impeller cannot be improved, the pump efficiency, the motor, the bracket and the main shaft are connected with low stability, so as to improve the wear condition and improve the stability and airtightness, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

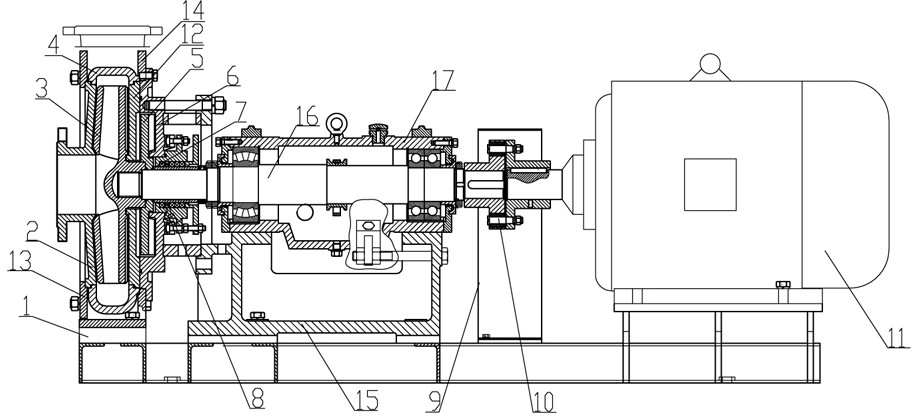

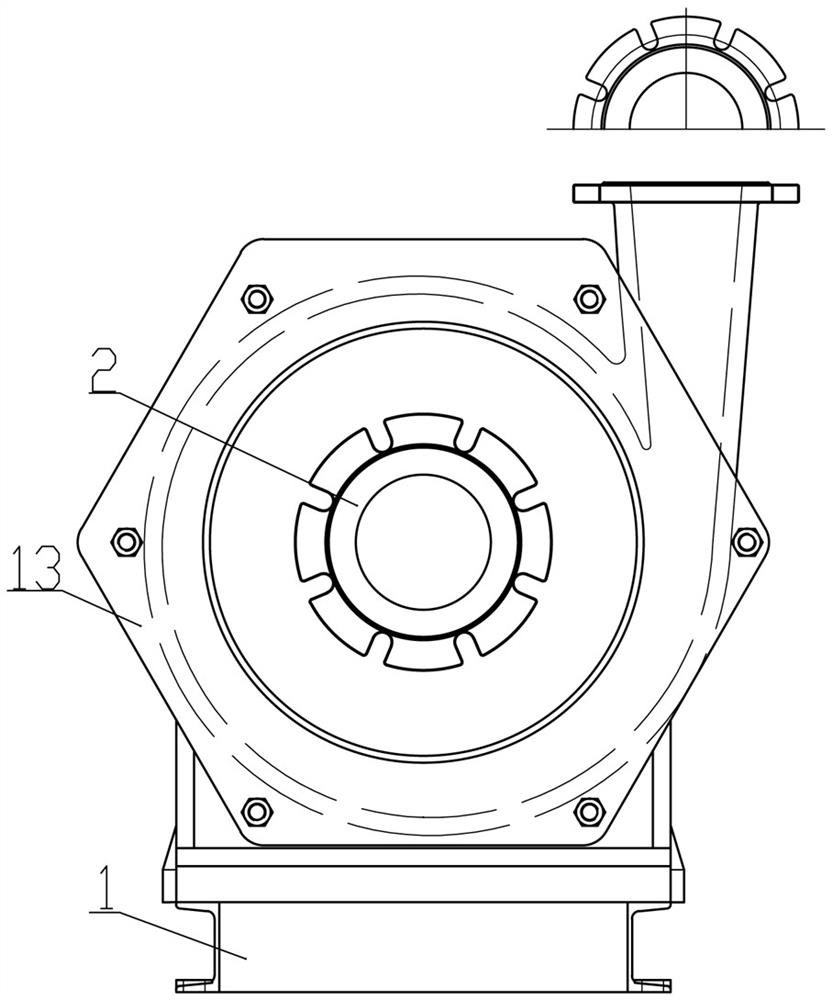

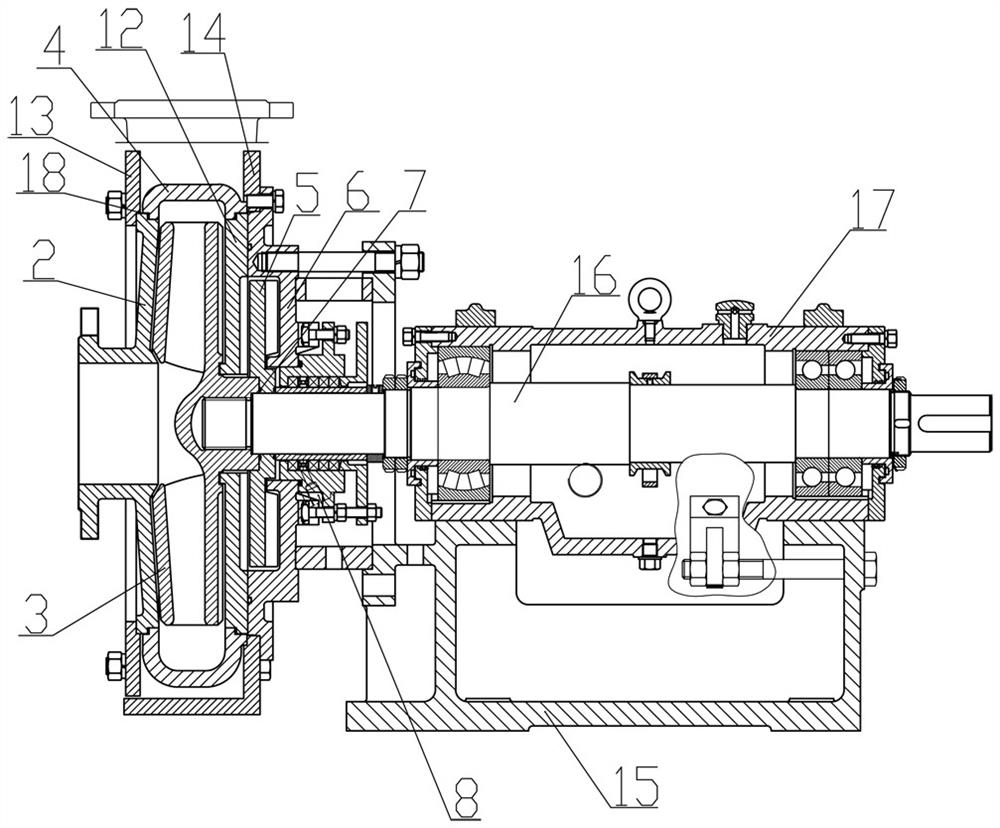

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is further described:

[0024] like Figure 1 to Figure 5 As shown, an impeller includes an impeller main body 19, and a plurality of circumferentially distributed blades 20 are arranged on the impeller main body 19. A single blade 20 is a variable-angle logarithmic spiral structure, and the blade 20 is from the impeller The center of the main body 19 is gradually twisted to the edge of the impeller main body 19, reducing the axial power of the pump, improving the hydraulic efficiency, and improving the efficiency of the pump; the thickness of the blade 20 is gradually thinned from the edge of the impeller main body 19 to the center of the impeller main body 19, improving the blade 20. The wear condition of the blade 20 is prevented from clogging; the variable-angle logarithmic spiral structure refers to the algorithm of the logarithmic spiral according to the algorithm of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com