a water body structure

A water outlet and water outlet technology, which is applied to liquid fuel engines, parts of pumping devices used for elastic fluids, non-variable pumps, etc., can solve the problem that the inner chamber of the water outlet does not conform to the law of efficient fluid flow and the waste of casting materials , increase shaft power and other issues, to achieve a good diversion effect, improve head and efficiency, and reduce hydraulic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

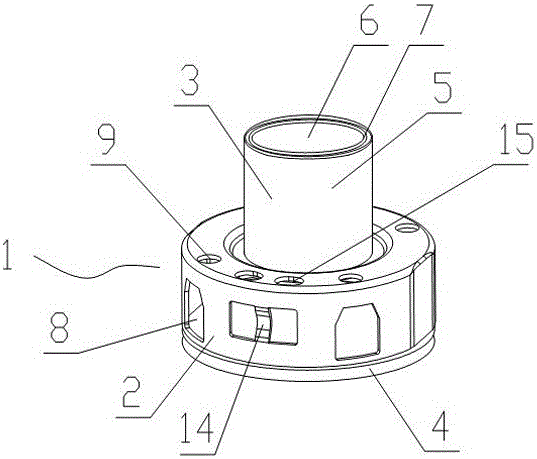

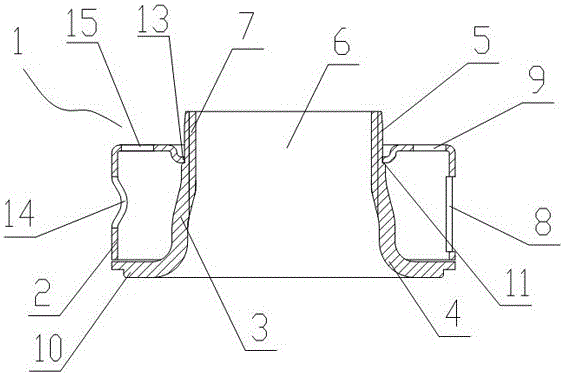

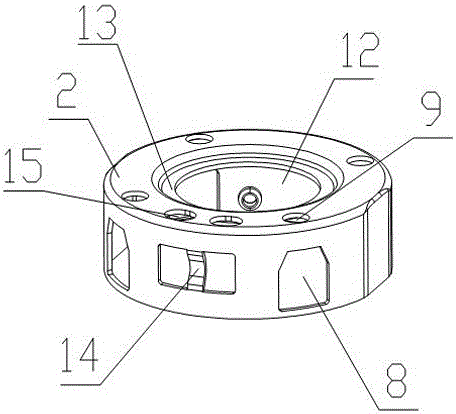

[0022] exist figure 1 , figure 2 In the shown embodiment, a water outlet structure includes a water outlet body 1, the water outlet body 1 includes a water outlet cover 2 and a water outlet inner lining 3, and the water outlet cover 2 and the water outlet inner lining 3 are steel stamping components respectively . The water outlet body cover 2 is set on the water outlet inner lining 3 and is clamped and connected with the outer wall of the water outlet inner lining 3. The water outlet inner lining 3 includes a water inlet end 4 and a water outlet end 5, and the water outlet end 5 protrudes from the water outlet body cover. 2, a fluid cavity 6 with a smooth stepped structure is provided inside the inner lining 3 of the water outlet, and an internal thread 7 is provided on the cavity wall of the fluid cavity 6 at one end of the water outlet 5, and the side surface of the water outlet cover 2 is evenly distributed along the circumference. There are at least two notches 8 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com