Low-pressure steam generation system of scalding basin

A low-pressure steam generation system technology, applied in the field of stirring water supply system, can solve the problems of increasing demand for heating steam, increasing production cost, doubled steam consumption, etc., and achieves increased safety, low equipment cost, and reduced shaft power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

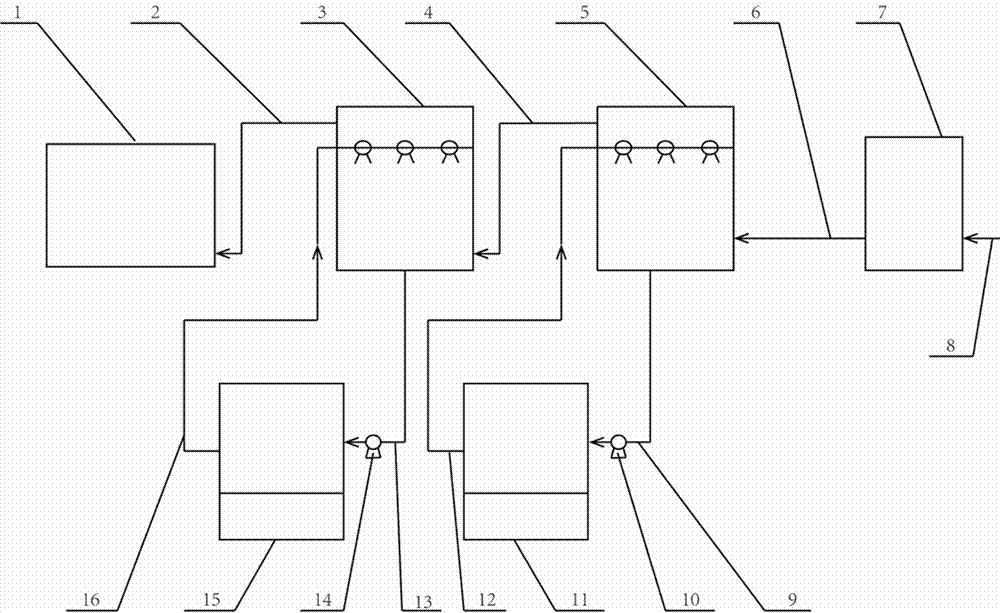

[0019] Such as figure 1 , This embodiment includes a scalding pool 1, a blower 7 with a blower inlet 8 and a blower outlet pipe 6, and a low-pressure steam generator. The low-pressure steam generator includes a primary low-pressure steam generator 5 and a secondary low-pressure steam generator 3 . Wherein the inlet end of the first-level low-pressure steam generator 5 is connected with the blower outlet pipe 6 as the inlet end of the low-pressure steam generator, and the outlet end of the first-level low-pressure steam generator 5 is connected with the second-level low-pressure steam through the first-level outlet pipe 4 The inlet end of the generator 3 and the outlet end of the secondary low-pressure steam generator 3 are connected to the scalding pool 1 through the secondary outlet pipe 2 as the outlet end of the low-pressure steam generator.

[0020] Blower 7 can also be arranged on secondary outlet pipe 2 ends, blower air inlet 8 connects secondary outlet pipe 2, blower o...

Embodiment 2

[0027] This embodiment includes a scalding pool, a blower with a blower air inlet and a blower outlet pipe, and a set of low-pressure steam generator, which is provided with a spray water device, and the spray water The water inlet end of the device is connected with a water inlet pipe, and the outlet pipe of the low-pressure steam generator is connected with a water heating device, and the water outlet end of the water heating device is connected with the water inlet pipe; the inlet end of the low-pressure steam generator is connected with the blower outlet pipe , the gas outlet is connected to the scalding pool.

[0028] The blower can also be arranged at the front end of the scalding pool. The air inlet of the blower is connected to the gas outlet of the low-pressure steam generator, and the outlet pipe of the blower is connected to the scalding pool, and steam is directly blown into the scalding pool. Correspondingly, the low-pressure steam generator needs to have a separ...

Embodiment 3

[0031] The water heating device described in this embodiment is a hot water boiler. Others are the same as embodiment two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com