Air compressor with adjustable oil injection quantity

A technology of fuel injection quantity and air compressor, applied in mechanical equipment, machine/engine, liquid variable capacity machinery, etc., can solve the problem of low compressor energy efficiency, the fuel injection quantity is still the original fuel injection quantity, and the improvement is limited and other problems, to achieve the effect of improving volumetric efficiency, saving fan power, and improving the saving rate

Inactive Publication Date: 2016-11-16

SAZHEN COMPRESSOR SHANGHAI CO LTD

View PDF13 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] As we all know, if the oil injection volume of the compressor is too small, the temperature of the main engine will be high, which will affect the efficiency of the compressor and the life of the lubricating oil. If the oil injection volume of the compressor is too large, it will also affect the energy efficiency of the compressor.

The permanent magnet motor can solve the problem of lower motor efficiency at low frequency of the air compressor, but it cannot solve the problem of lower efficiency of the main engine at low frequency (the compression volume of the main engine is reduced at low frequency, but the fuel injection volume is still the original fuel injection volume); fan frequency conversion The oil injection temperature can be adjusted to slightly improve the problem of the efficiency decrease of the main engine under low frequency conditions, but the improvement is limited

[0004] The main engine of the air compressor is designed in order to take into account different working conditions, different power ranges, different pressures, and different fuel injection volumes in different seasons. When we use it, the main engine may not operate at the best efficiency point most of the time. This will invisibly generate waste

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0049] In the air compressor with adjustable fuel injection quantity in this embodiment, except for using 2 to 3 solenoid valves instead of motor valves; other components remain unchanged.

[0050] The method of connecting 2 to 3 solenoid valves has limited control accuracy, which is not as flexible and precise as the motor valve. The principle of control is the same and will not be repeated here.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

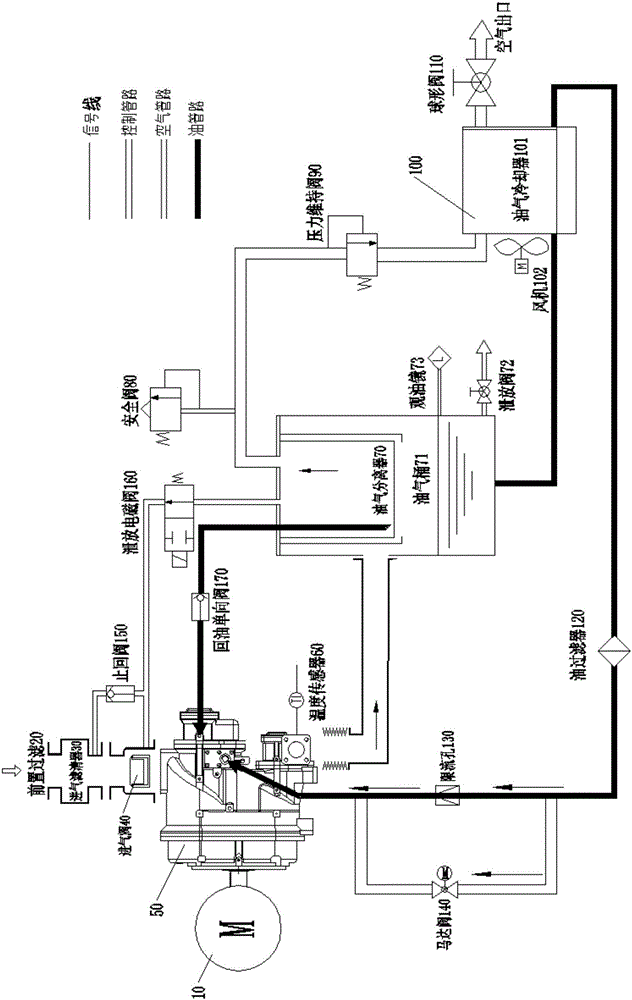

The invention provides an air compressor with the adjustable oil injection quantity. The air compressor comprises a main body and an oil-gas cooler. The main body and the oil-gas cooler are connected through an oil pipeline. The air compressor further comprises a flow-limiting hole, a bypass pipe and a valve. The oil pipeline is provided with the flow-limiting hole. The bypass pipe is arranged at the flow-limiting hole. The valve is arranged on the bypass pipe. The air compressor has the advantages that the flow-limiting device is additionally arranged on a main oil injection pipeline, and the value is obtained through calculation according to the optimal state of the main body under various working conditions, powers, pressures and seasons and the minimum oil quantity capable of meeting gear, bearing and rotor lubricating requirements. Due to the fact that the bypass pipe is additionally arranged on one side of the flow-limiting hole and the bypass pipe is additionally provided with the valve, the caliber of the bypass pipe can be adjusted by controlling the valve, the oil injection quantity can be kept optimal all the time, and the air compressor efficiency achieves optimization.

Description

technical field [0001] The invention relates to an air compressor, in particular to an air compressor with adjustable fuel injection volume. Background technique [0002] With the progress of society and the improvement of energy-saving awareness, the air compressor industry is no longer the era that only needs to produce gas, but ushered in the trend of energy-saving. How to manufacture extreme energy-saving products and let users directly see the energy-saving Effects became our top priority. [0003] As we all know, if the oil injection volume of the compressor is too small, the temperature of the main engine will be high, which will affect the efficiency of the compressor and the life of the lubricating oil. If the oil injection volume of the compressor is too large, it will also affect the energy efficiency of the compressor. The permanent magnet motor can solve the problem of lower motor efficiency at low frequency of the air compressor, but it cannot solve the proble...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F04B39/02

CPCF04B39/0207

Inventor 张清源丁刚程红星廖铁强吴金勇

Owner SAZHEN COMPRESSOR SHANGHAI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com