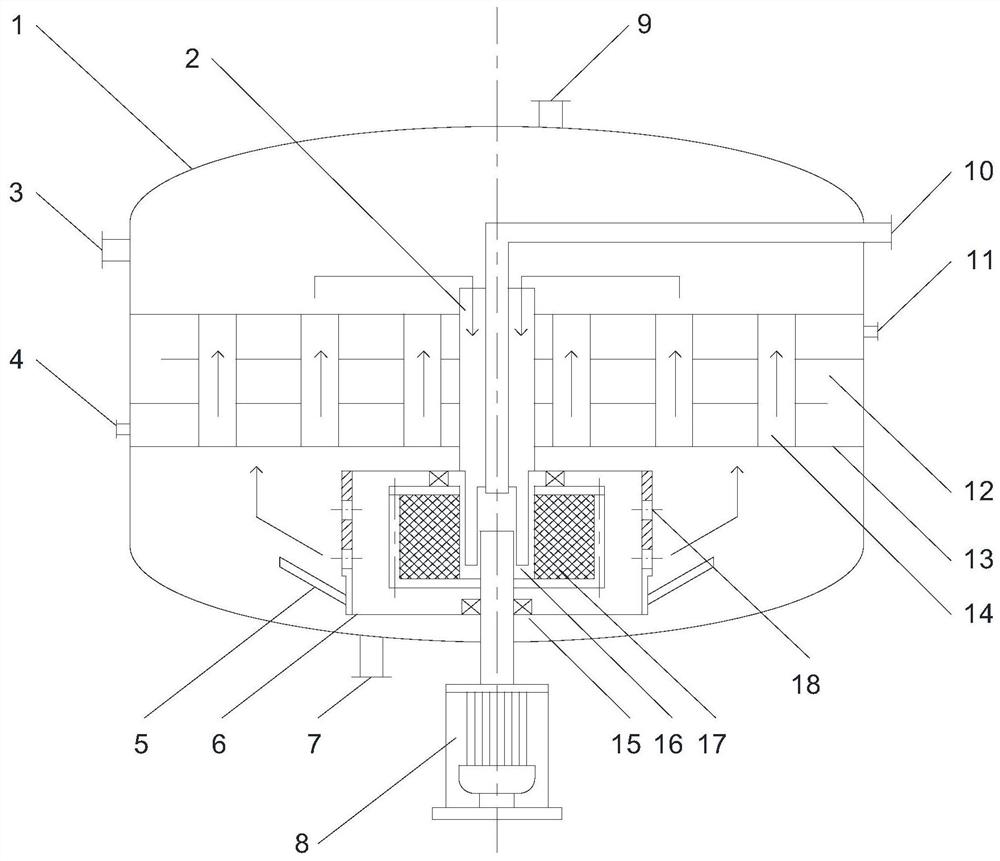

Immersed rotating filling bed reactor and application

A technology of rotating packed bed and reactor, applied in the field of reactors, can solve the problems of limited effect and cumbersome process of adding the third phase solvent, and achieve the effects of high internal air pressure, saving shaft power, and good dispersion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The submerged rotary packed bed reactor of the present invention is used to carry out the reaction of p-nitrophenol in ozone degradation water, and the gaseous ozone concentration is 20 mg L -1 , from the feed port, through the inner pipe of the feed assembly to the filler, the concentration of p-nitrophenol in the solution in the reactor is 100mg·L -1 , the rotation speed of the rotating packed bed is 500r / min~6000r / min, after full reaction, the removal rate of p-nitrophenol can reach about 95%, the mass transfer of ozone is enhanced, and the amount of dissolved ozone is increased.

Embodiment 2

[0056] The submerged rotary packed bed reactor of the present invention is used to carry out the reaction of acid red B in ozonated water, and the catalyst iron-cobalt double metal oxide is attached to the surface of the porous packing by chemical means. Put the solution into the reactor, turn on the cooling medium pump and the motor switch, and then inject ozone after the cycle is stable, and the rotation speed is 500r / min~6000r / min. The results showed that with the increase of the rotational speed, the removal rate of acid red B increased, and the removal rate increased significantly in the early stage of the increase of the rotational speed, but not in the later period. Under the optimal operating conditions, the removal rate of acid red B can reach about 98%, and the utilization rate of ozone is about 96%.

Embodiment 3

[0058] The liquid-liquid heterogeneous phase reaction of fatty acid methyl ester epoxidation is carried out by adopting the submerged rotating packed bed reactor of the present invention, using hydrogen peroxide as the oxygen source and formic acid as the oxygen carrier, the mass fraction of hydrogen peroxide used is 50%, and the mass fraction of formic acid The fraction is 86%, the molar ratio of double bond concentration to hydrogen peroxide concentration is 1:1.5, the molar ratio of double bond concentration to formic acid concentration is 1:0.23, the reaction temperature is 70°C, the volume fraction of the aqueous phase is about 0.3, and the rotating packed bed The rotating speed is 500r / min~6000r / min, and the epoxy value and iodine value of the obtained epoxy fatty acid methyl ester are 6 and 1.9 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com