Oil-free pendulum type air compressor

An air compressor and oil pendulum technology, which is applied in the direction of liquid variable capacity machinery, mechanical equipment, variable capacity pump components, etc., can solve the problems of transmission devices that can only rotate forward, installation, use restrictions, and large friction surfaces of bearing pads. , to achieve the effect of reducing heat conduction area, ensuring lubrication safety and increasing torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

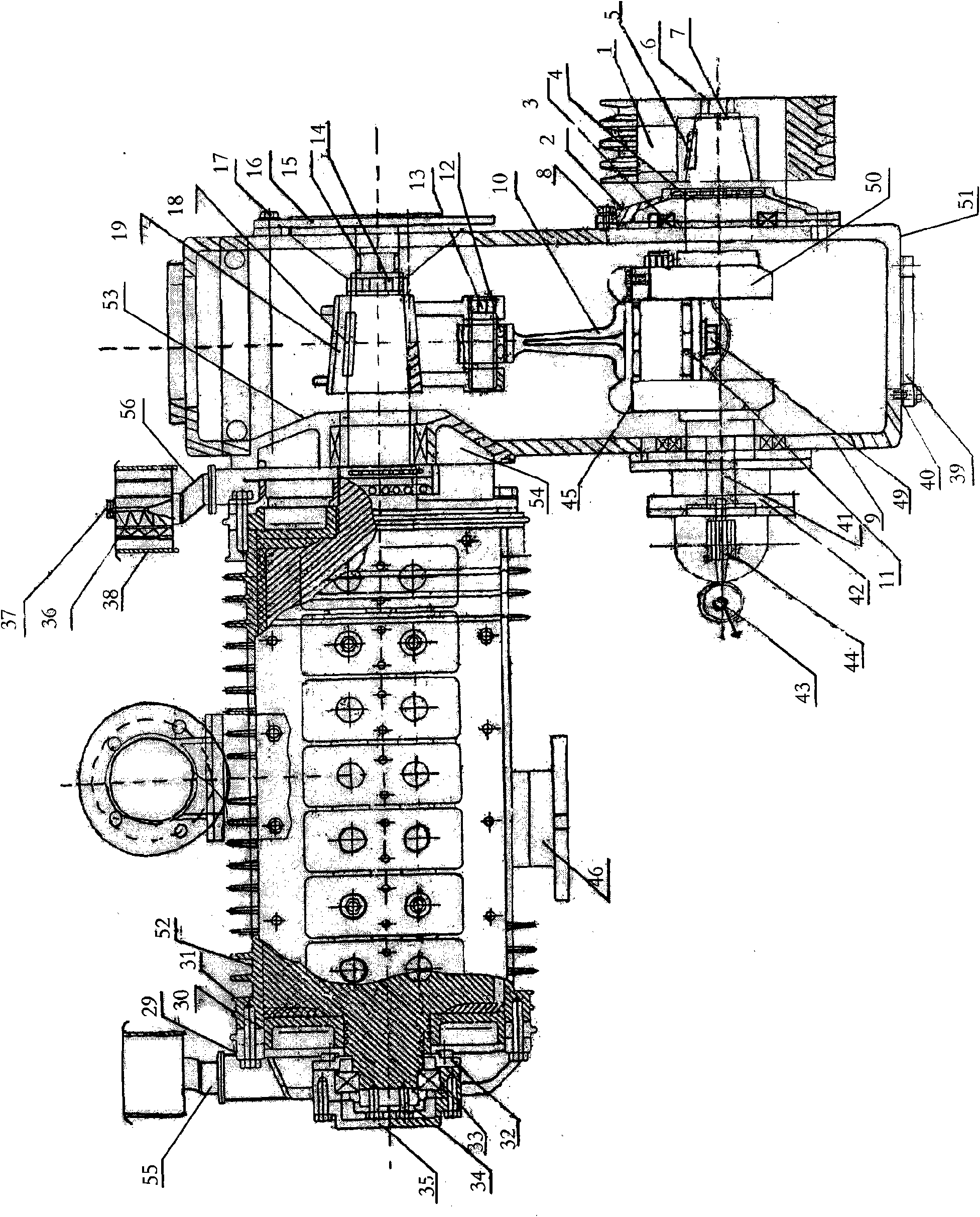

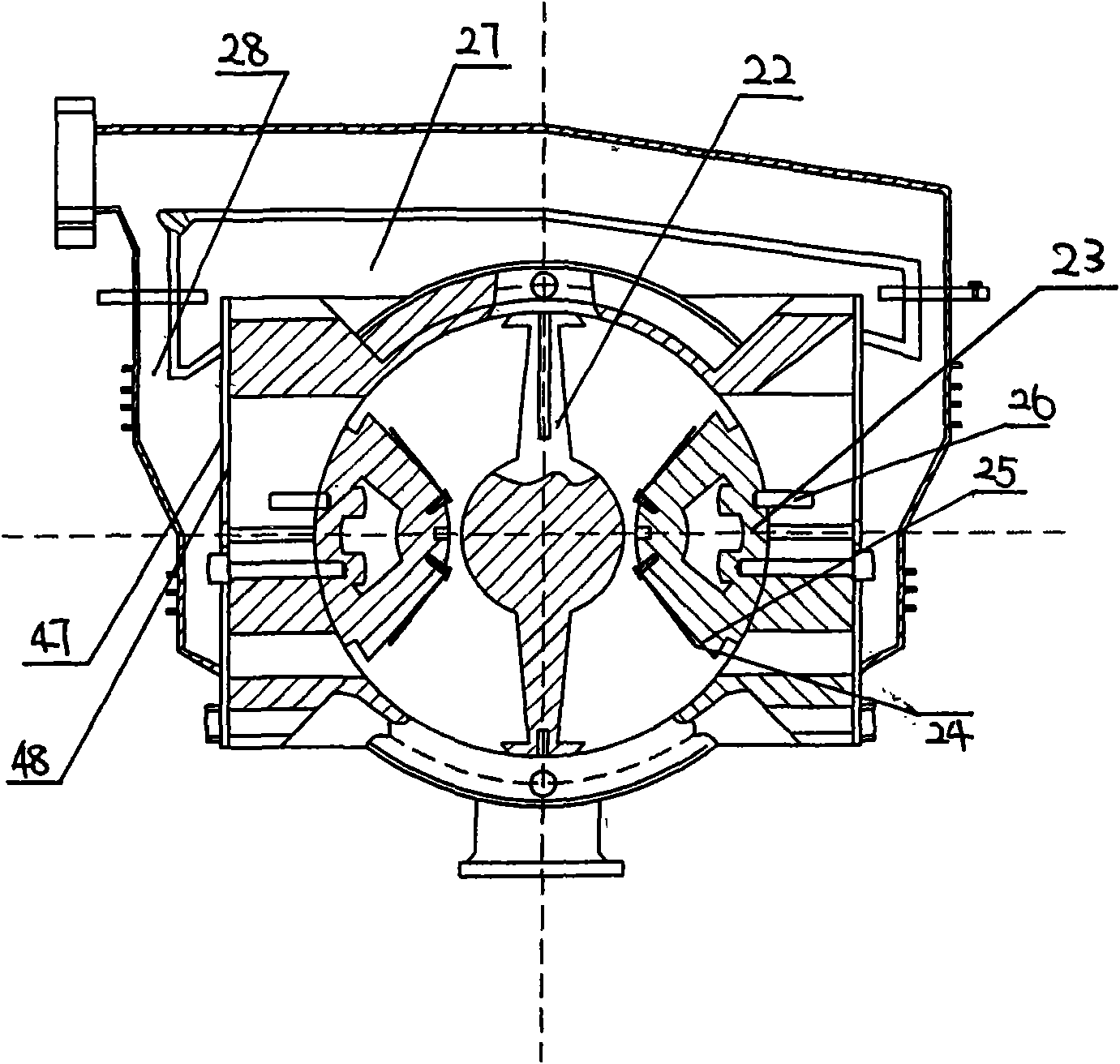

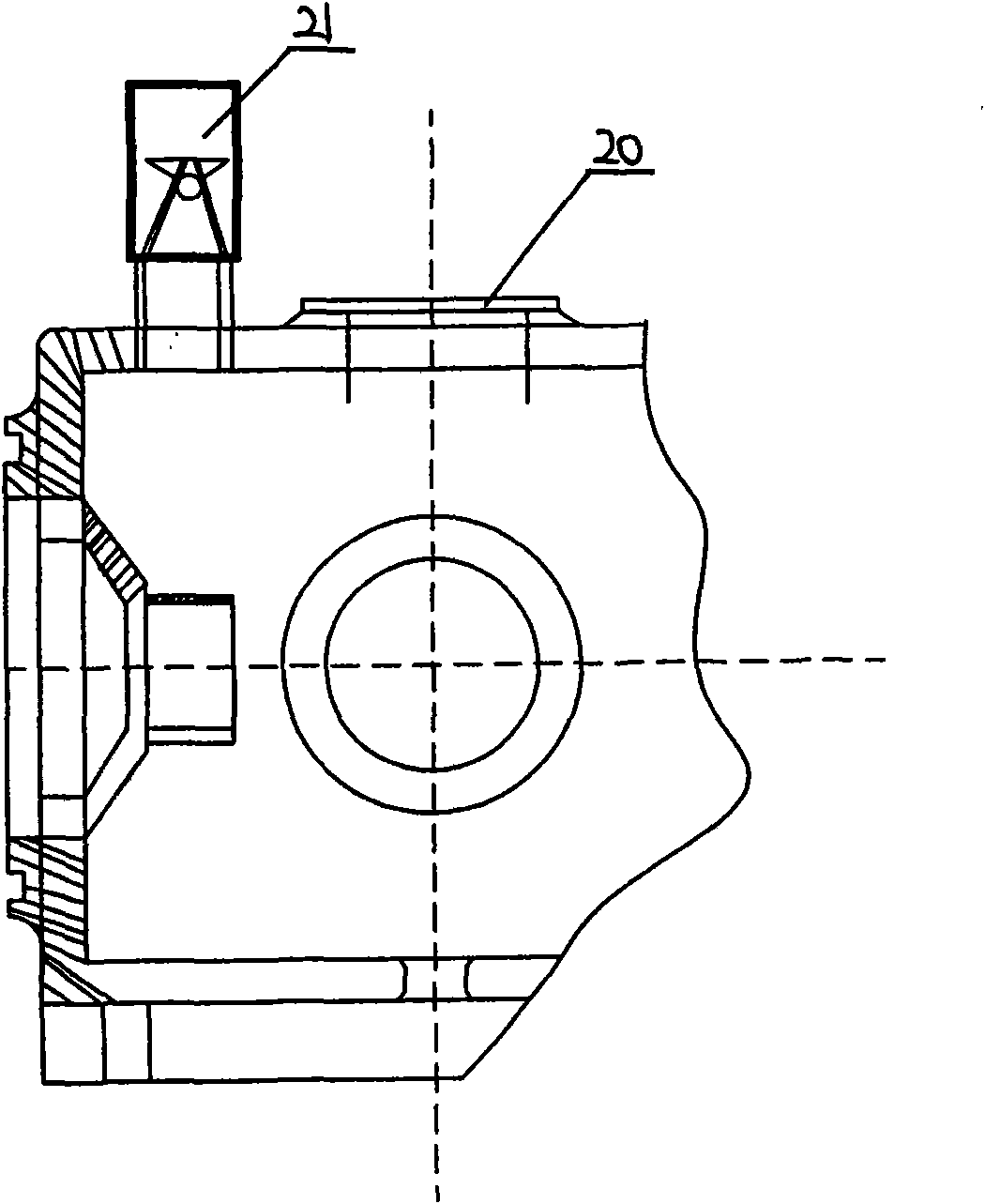

[0011] The transmission device of the oil-free pendulum type air compressor of the present invention includes connecting rod 10, crankcase 9, rotor 22, cylinder 52, support 46, sensor, pulley 1, wherein crankshaft 50 is contained on the fuselage shell 51, connecting rod 10 Installed on the crankshaft 50, the other end of the connecting rod 10 passes through one end of the shaft of the rotor 22, the rotor 22 is installed in the cylinder 52, the pulley 1 is installed at one end of the crankshaft 50, and the sensor seat is installed at the other end; the cylinder 52 is fixed with Valve table 23 can be produced by general air compressor factory. The connecting rod 10 of the present invention is installed on the crankshaft 50 through the pin shaft, and the rolling bearing 11 is housed between the connecting rod 10 and the pin shaft, and is evenly distributed on the connecting end surface of the connecting piece 53 between the cylinder 52 and the fuselage shell 51. There are several...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com