Device and method for deep aeration in integrated oxidation ditch

The technology of an aeration device and aeration method is applied in chemical instruments and methods, aerobic and anaerobic process treatment, water/sludge/sewage treatment, etc., and can solve the problem of high operating cost of activated sludge aerators, aeration Difficulty in maintaining, repairing and replacing the inflator, evacuation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

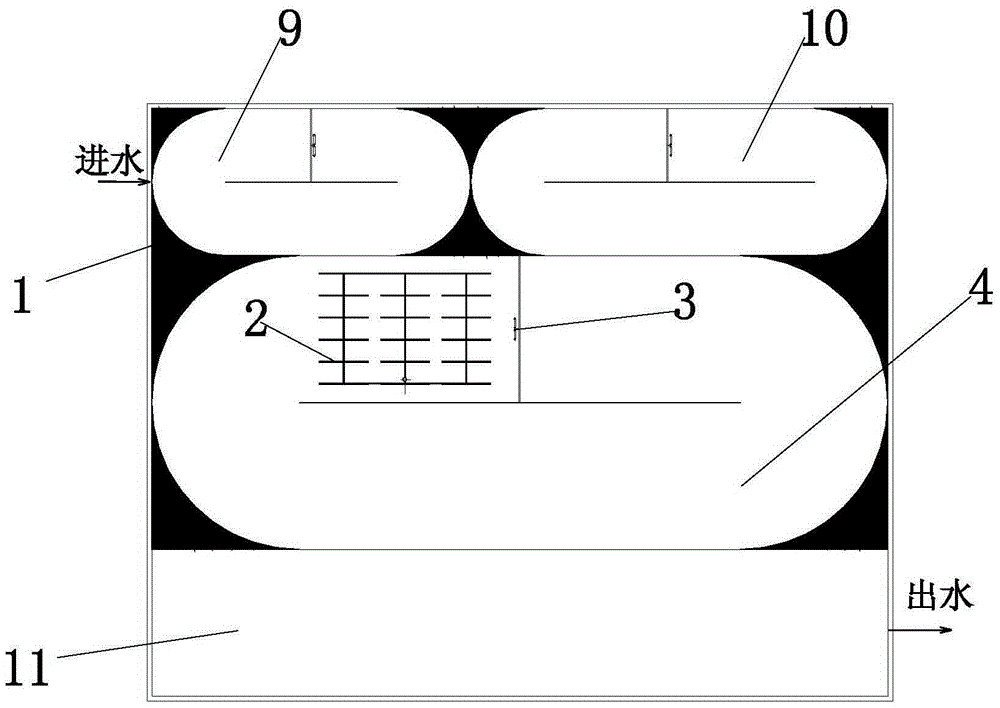

[0038] Such as figure 1 and figure 2 As shown, an integrated oxidation ditch mid-deep aeration device includes an integrated oxidation ditch 1, several mid-deep aerators 2, and underwater propellers 3;

[0039] An anaerobic reaction pool, an anoxic reaction pool, an aerobic reaction pool 4, and a sedimentation pool 11 are sequentially arranged in the integrated oxidation ditch body 1 along the sewage flow direction;

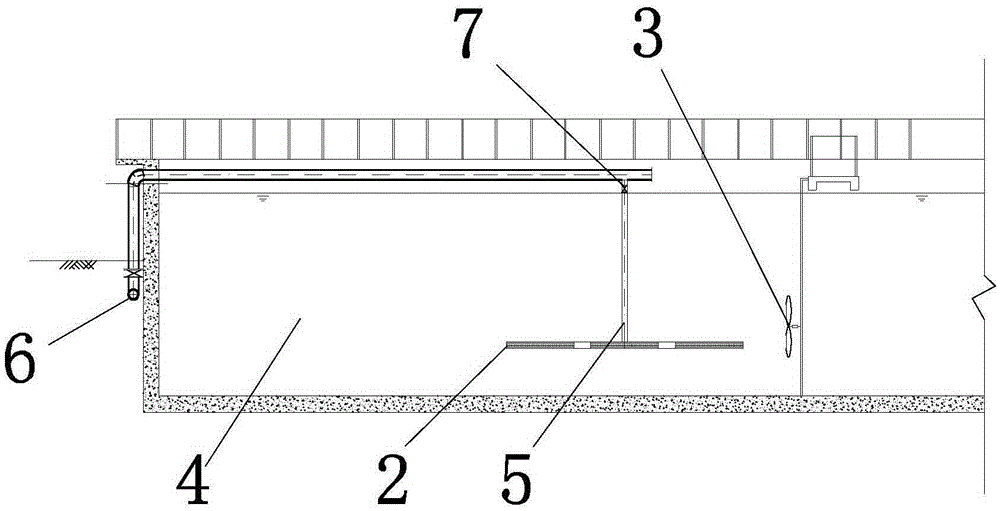

[0040] The middle-deep aerator 2 adopts a microporous aerator, which is horizontally installed at 1.5 meters away from the bottom of the aerobic reaction tank 4; 6 connection; the electric valve 7 is connected to the mid-deep layer aerator, and the electric valve 7 is connected to the automatic control system 8.

[0041] The underwater propeller 3 is vertically installed in the aerobic reaction tank 4, and the depth matches the mid-deep aerator 2; the cable of the underwater propeller 3 is connected to the power supply through a guide rod.

[0042] The workin...

Embodiment 2

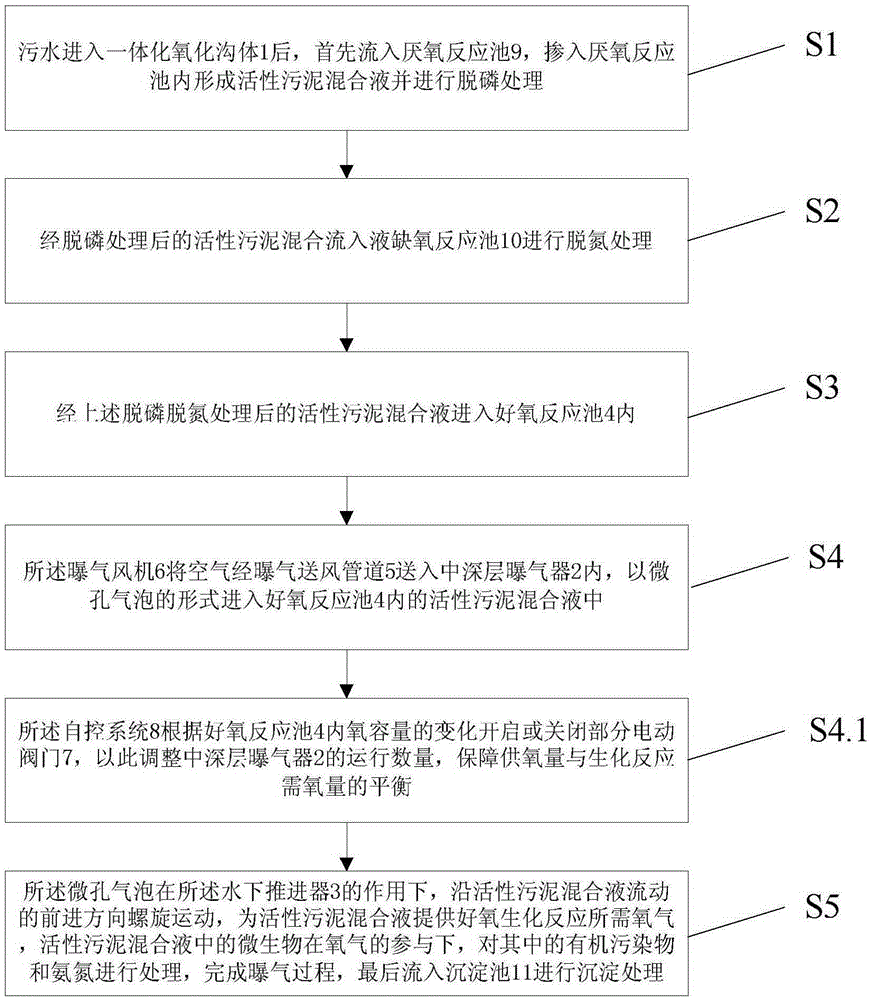

[0045] Such as image 3 Shown, a deep aeration method in an integrated oxidation ditch, comprising steps:

[0046] After S1 sewage enters the integrated oxidation ditch body 1, it first flows into the anaerobic reaction tank 9, and is mixed into the anaerobic reaction tank to form an activated sludge mixture and undergo dephosphorization treatment;

[0047] S2 The activated sludge after the dephosphorization treatment is mixed and flows into the liquid anoxic reaction tank 10 for denitrification treatment;

[0048] S3 The activated sludge mixed solution after the above-mentioned dephosphorization and denitrification treatment enters the aerobic reaction tank 4;

[0049] The aeration fan 6 described in S4 sends the air into the middle-deep aerator 2 through the aeration air supply pipe 5, and enters the activated sludge mixed solution in the aerobic reaction tank 4 in the form of microporous air bubbles;

[0050] Under the action of the underwater propeller 3, the microporous...

Embodiment 3

[0056] Compared with Embodiment 1, this embodiment has a plurality of aerobic reaction tanks 4 connected in series, and a plurality of middle-deep aerators 2 are arranged in each aerobic reaction tank 4 along the sewage flow direction,

[0057] The integrated oxidation ditch body 1 of this embodiment is provided with functional areas including an aerobic reaction pool 4, such as anaerobic reaction pools, anoxic reaction pools, sedimentation tanks, etc., and sewage enters the integrated oxidation ditch body 1 After that, it flows into each functional area in turn, and is mixed into the activated sludge mixture in each functional area for treatment; the activated sludge mixture first enters the anaerobic reaction tank, and the activated sludge is mixed under the action of anaerobic bacteria. dephosphorization treatment; the dephosphorized activated sludge mixed solution flows into the anoxic reaction tank, under the action of anoxic bacteria, the activated sludge mixed solution i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com