Full-scale performance detection and evaluation device of SCR (selective catalytic reduction) denitration catalyst and application method thereof

A denitrification catalyst and evaluation device technology, which is applied in the field of SCR denitrification catalyst full-scale performance detection and evaluation device, can solve the problems of energy waste and low efficiency, and achieve the effect of uniform heating temperature and low heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

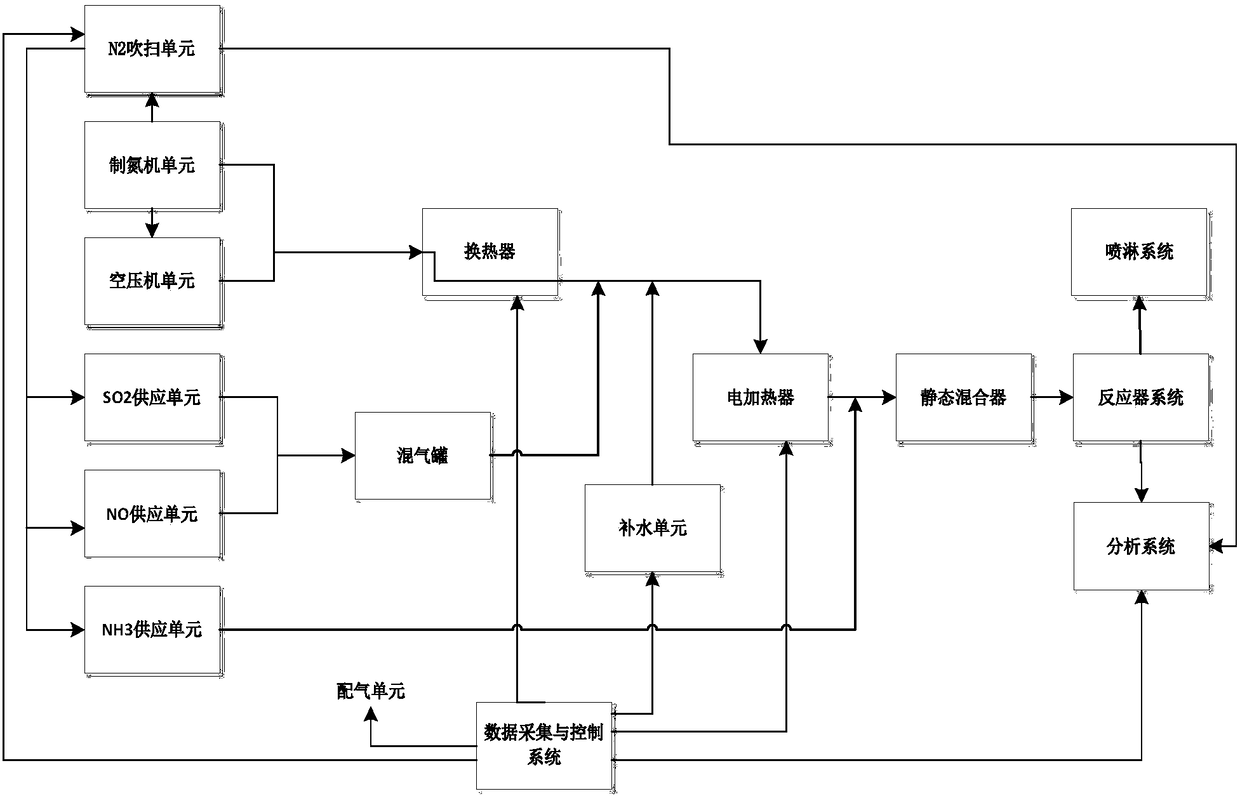

[0047] Such as figure 1 As shown, a full-scale performance testing and evaluation device for SCR denitrification catalyst, including gas distribution system, main reaction system, analysis system, spray system, data acquisition and control system, the gas distribution system is connected with the main reaction system, and the analysis system is connected with The reactor system of the main reaction system is connected with the data acquisition and control system, the spray system is connected with the reactor system of the main reaction system, and the data acquisition and control system is respectively connected with the gas distribution system and the main reaction system.

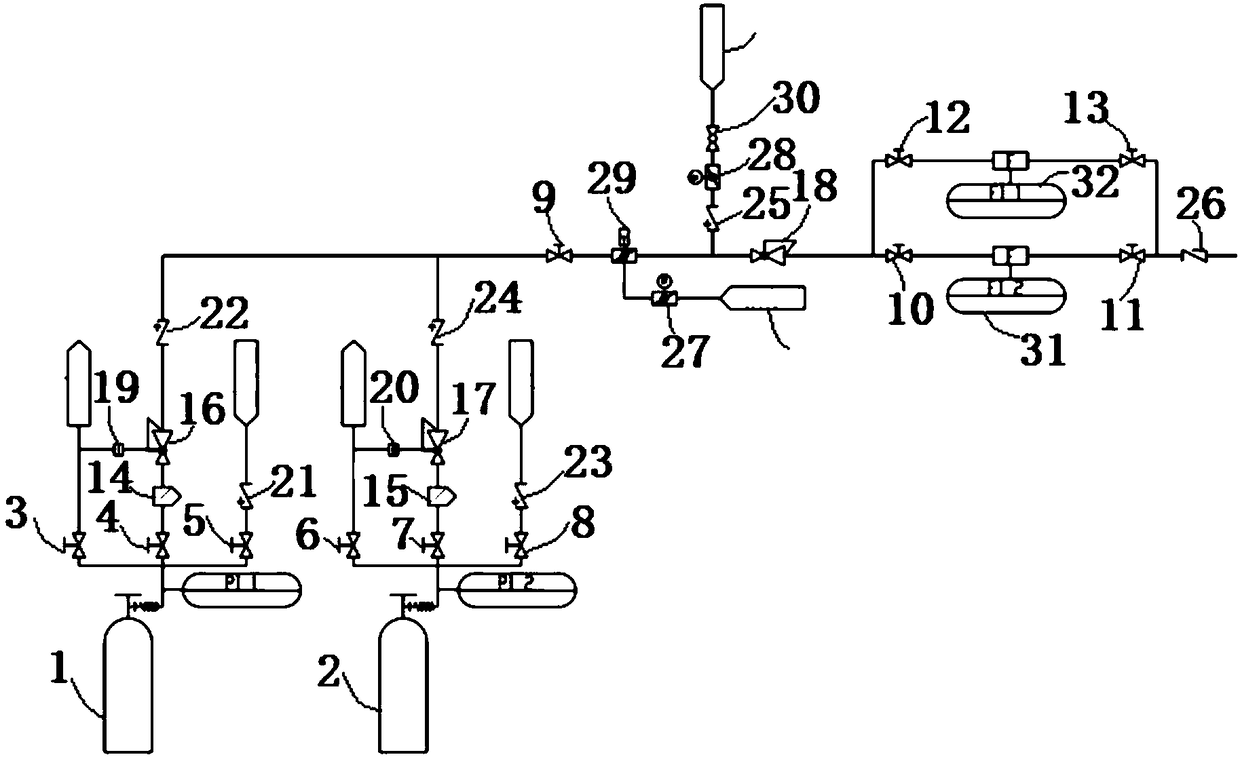

[0048] Among them: the gas distribution system is used to provide the raw gas N that satisfies the composition ratio of the simulated flue gas 2 , O 2 , SO 2 , NO, NH 3The gas distribution with water vapor is composed of a gas distribution unit, a water supply unit and a gas mixing tank. The gas distr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com