Flue gas wet desulphurization, dedusting integrated device and process

A wet desulfurization and flue gas technology, applied in the field of dust removal synergistic process and wet desulfurization, can solve the problems of secondary pollution of flushing fluid, high operation and maintenance costs, and single implementation content, so as to prevent secondary atomization and improve dust removal. The effect of defogging efficiency and improving replenishment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

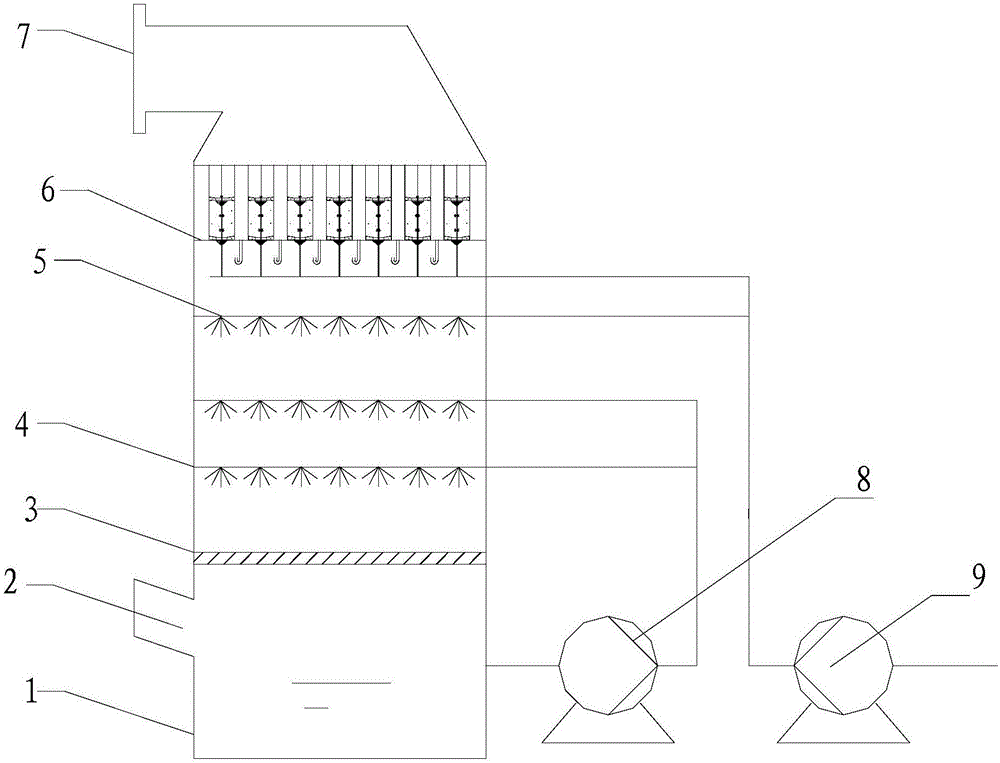

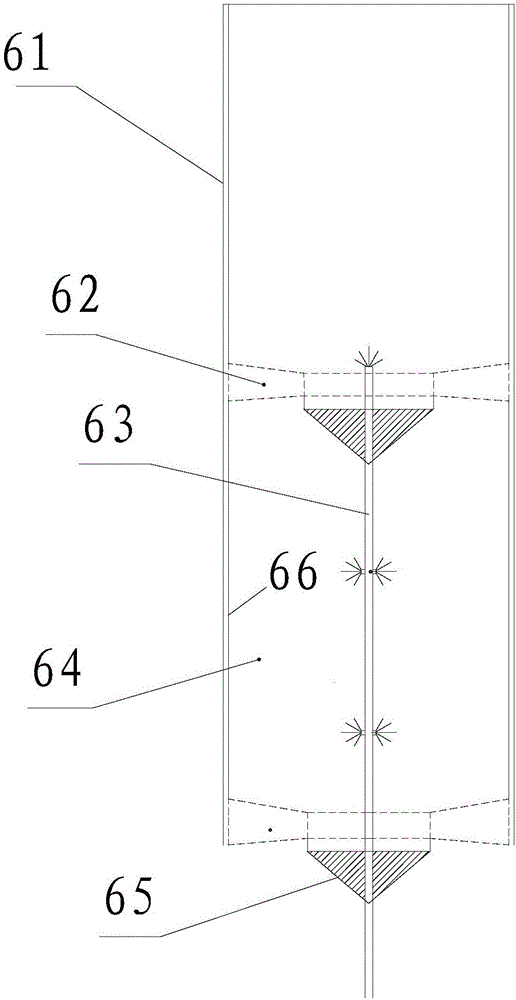

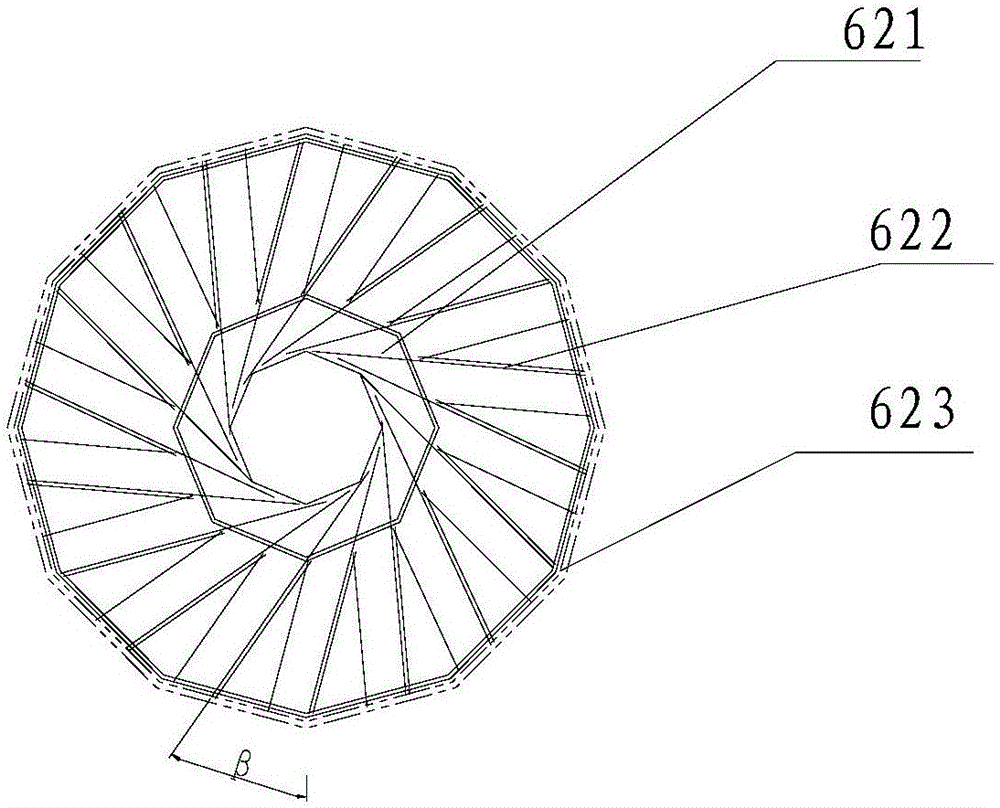

[0071] A sintering plant, 2 sets 280m 2 The new desulfurization project of sintering flue gas adopts this process, and the SO in the inlet flue gas 2 The concentration is 1785mg / m 3 , the dust concentration in the inlet flue gas is 62mg / m 3 ;3-layer spraying, circulating slurry liquid-gas ratio 9.5L / Nm 3 ; The height of the ultra-fine atomization cooling zone is 3.5m, the average atomization particle size of the ultra-fine atomization nozzle is 54μm, and the liquid-gas ratio is 0.1L / Nm 3 ; The number of layers of the swirl module is 3 layers, the distance between two adjacent layers of swirl modules is 2.5 times the diameter of the cross-section of the hollow guide tube, the diameter of the drain hole on the upper wall of the module is 6mm, and the diameter of the central blind plate is the horizontal diameter of the hollow tube. 0.5 times the diameter of the section, the height of the upper cylinder of the conical device is 1cm, the cone angle of the lower inverted cone is...

Embodiment 2

[0073] In a thermal power plant, the flue gas desulfurization renovation project of two 75WM units adopts this process, and the SO in the inlet flue gas 2 The concentration is 1839mg / m 3 , the dust concentration in the inlet flue gas is 53mg / m 3 ;3-layer spraying, circulating slurry liquid-gas ratio 14.3L / Nm 3 ; The height of the ultra-fine atomization cooling zone is 3.0m, the average atomization diameter of the nozzle is 62μm, and the atomization liquid-gas ratio is 0.1L / Nm 3 ; The number of layers of the swirl module is 3 layers, the distance between two adjacent layers of swirl modules is 2.0 times the diameter of the cross-section of the hollow guide tube, and the diameter of the drain hole on the upper wall of the module is 6mm; the diameter of the central blind plate is the horizontal diameter of the hollow tube. 0.5 times the diameter of the section, the horizontal angle of the swirl blade is 30°, the angle between the upper edge of the swirl blade and the radius is ...

Embodiment 3

[0075] A self-provided electroplating power plant, a 360t / h boiler flue gas desulfurization renovation project adopts this process, SO in the inlet flue gas 2 The concentration is 1583mg / m 3 , the dust concentration in the inlet flue gas is 45mg / m 3 ;3-layer spraying, circulating slurry liquid-gas ratio 13.5L / Nm 3; The height of the ultra-fine atomization cooling zone is 2.5m, the average atomization diameter of the nozzle is 62μm, and the atomization liquid-gas ratio is 0.15L / Nm 3 ; The number of layers of the swirl module is 3 layers, the distance between two adjacent swirl modules is 2.0 times the diameter of the cross section of the hollow guide tube, the diameter of the drain hole on the upper wall of the module is 5mm, and the diameter of the central blind plate is the horizontal diameter of the hollow tube. 0.5 times the diameter of the section, the horizontal angle of the swirl blade is 30°, the angle between the upper edge of the swirl blade and the radius is 35°, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com