Nylon 66 material and preparation method thereof

A nylon and raw material technology, applied in the field of nylon 66 material and its preparation, can solve the problems of large amount of preparation, low production efficiency, long casting cycle, etc., achieve high production efficiency, strong practicability, and improve the interface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Drying preparation: place the nylon 66 raw material in a desiccator to dry; drying temperature: 90-100°C; drying time: 6-8 hours;

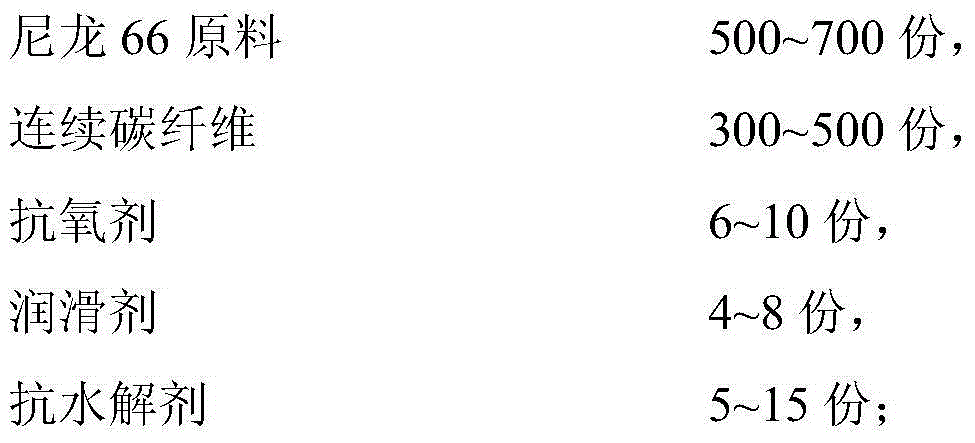

[0041] (2) Weigh each raw material (parts by weight) according to the following proportions, and add them to the high mixer one by one. The mixing temperature is controlled at 40-60°C, and the mixing time is 3-5 minutes. The material is added to the hopper of the extruder for standby, and the drying temperature of the hopper of the extruder is set at 80-90°C;

[0042] Nylon 66 raw material 700 parts,

[0043] Continuous carbon fiber 300 parts,

[0044] Antioxidant 9 parts,

[0045] 5 parts lubricant,

[0046] Anti-hydrolysis agent 8 parts.

[0047] The melt index of nylon 66 raw material is 10-30g / 10min, and the test condition is 275°C, 0.325Kg;

[0048] The continuous carbon fiber is acrylonitrile-based continuous carbon fiber, the fiber diameter is 7μm, and the linear density is 3200g / 1000m;

[0049] Antioxidants include N,N'-bi...

Embodiment 2

[0062] (1) Drying preparation: place the nylon 66 raw material in a desiccator to dry; drying temperature: 90-100°C; drying time: 6-8 hours;

[0063] (2) Weigh each raw material (parts by weight) according to the following proportions, and add them to the high mixer one by one. The mixing temperature is controlled at 40-60°C, and the mixing time is 3-5 minutes. The material is added to the hopper of the extruder for standby, and the drying temperature of the hopper of the extruder is set at 80-90°C;

[0064] 600 parts of nylon 66 raw material,

[0065] Continuous carbon fiber 400 parts,

[0066] Antioxidant 9 parts,

[0067] 5 parts lubricant,

[0068] Anti-hydrolysis agent 8 parts.

[0069] The melt index of nylon 66 raw material is 10-30g / 10min, and the test condition is 275°C, 0.325Kg;

[0070] The continuous carbon fiber is acrylonitrile-based continuous carbon fiber, the fiber diameter is 7μm, and the linear density is 3200g / 1000m;

[0071] Antioxidants include N,N'...

Embodiment 3

[0084] (1) Drying preparation: place the nylon 66 raw material in a desiccator to dry; drying temperature: 90-100°C; drying time: 6-8 hours;

[0085] (2) Weigh each raw material (parts by weight) according to the following proportions, and add them to the high mixer one by one. The mixing temperature is controlled at 40-60°C, and the mixing time is 3-5 minutes. The material is added to the hopper of the extruder for standby, and the drying temperature of the hopper of the extruder is set at 80-90°C;

[0086] Nylon 66 raw material 500 parts,

[0087] Continuous carbon fiber 500 parts,

[0088] Antioxidant 9 parts,

[0089] 5 parts lubricant,

[0090] Anti-hydrolysis agent 8 parts.

[0091] The melt index of nylon 66 raw material is 10-30g / 10min, and the test condition is 275°C, 0.325Kg;

[0092] The continuous carbon fiber is acrylonitrile-based continuous carbon fiber, the fiber diameter is 7μm, and the linear density is 3200g / 1000m;

[0093] Antioxidants include N,N'-bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com