Leadless low-melting point glasses with very high refractive index and method for making same

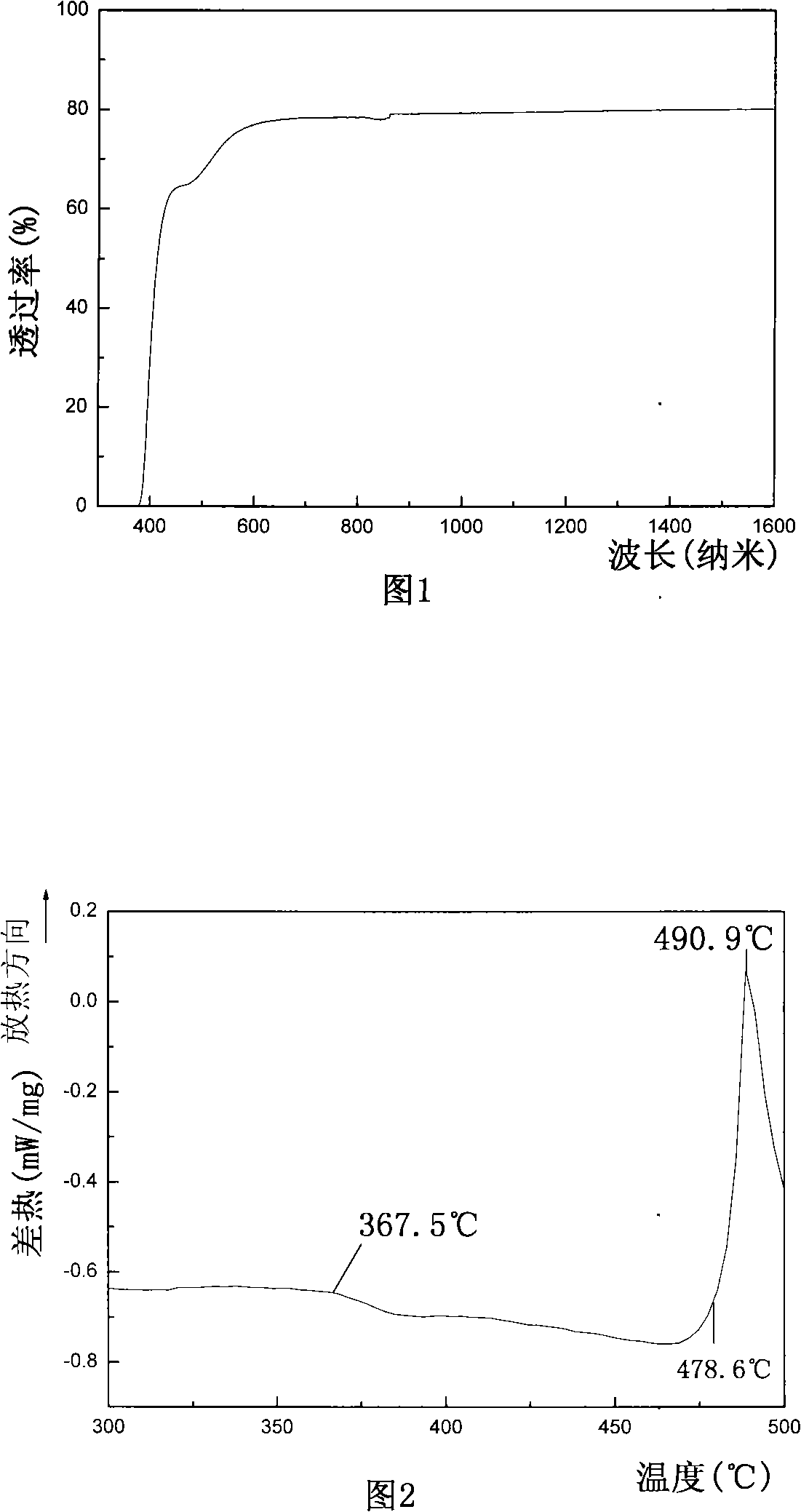

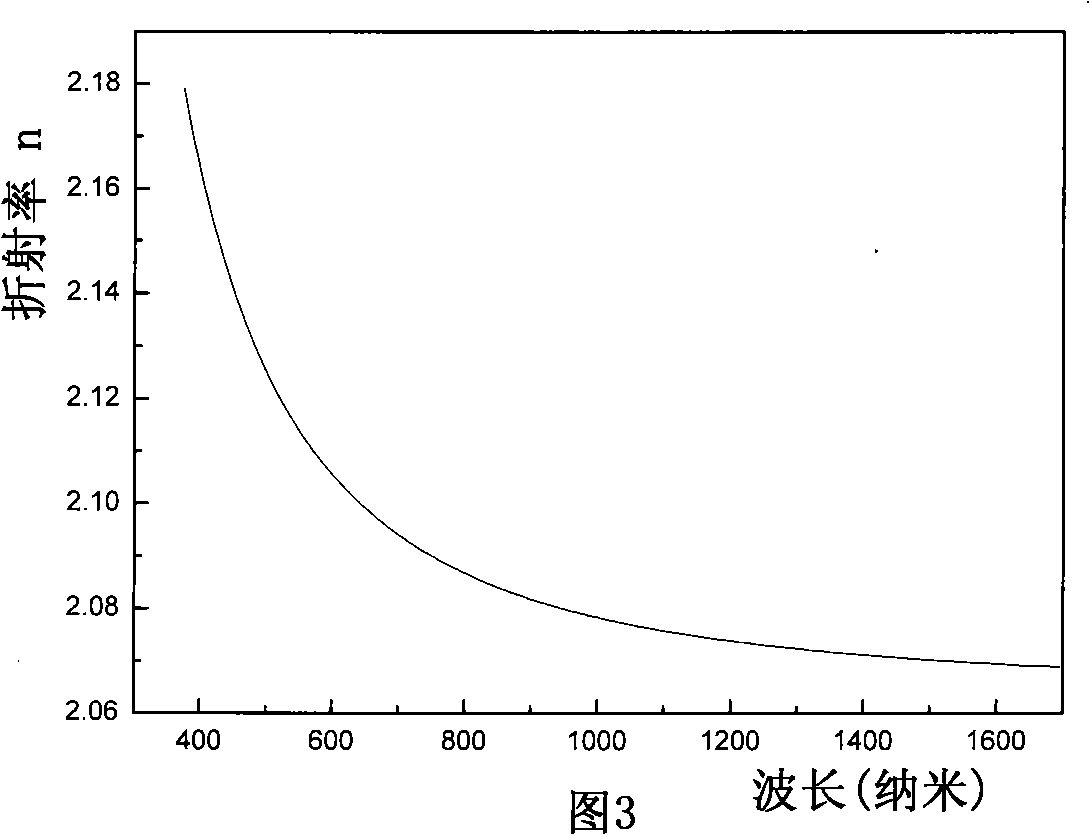

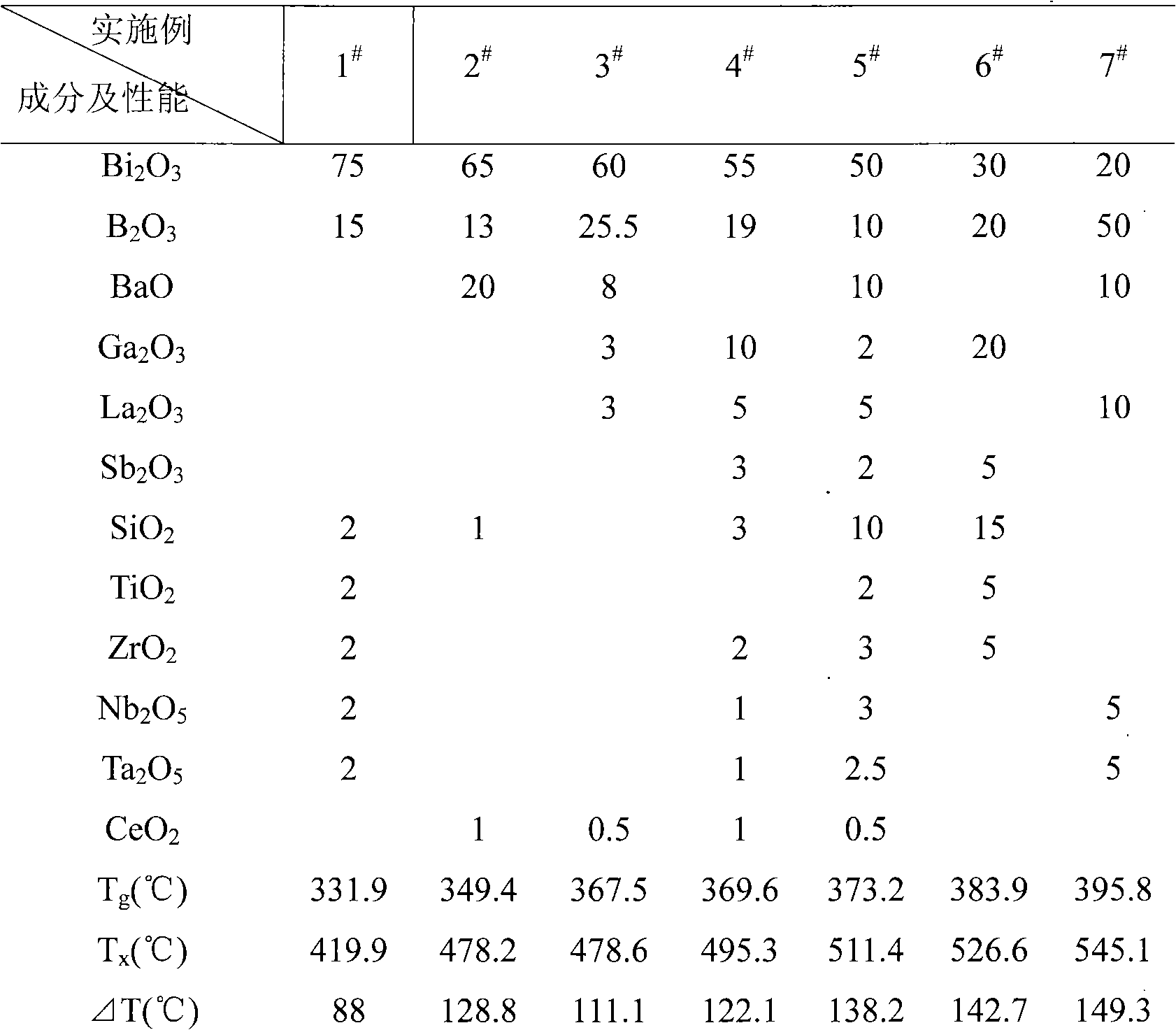

A high refractive index, low melting point technology, applied in the field of glass, can solve the problems of low glass refractive index, high glass transition temperature, low transmittance, etc., and achieve high refractive index, low glass transition temperature, and good thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1 # ~7 # :

[0038] Example 1 # ~7 # The composition and content are as in Table 1 1 # ~7 # Shown, specific preparation method comprises the following steps:

[0039] 1. Calculate the weight percentage of glass according to the mole percentage (mol%) of glass composition, then weigh the raw materials, mix them uniformly, and form a mixture;

[0040] ②Put the mixture into a corundum crucible, cover it, and place it in a silicon carbide rod electric furnace at 600°C for pre-sintering for 30 minutes to form a sintered material;

[0041] ③ Melt the sintered material in a silicon carbide rod electric furnace at 950-1050 ° C, and determine the length of melting time according to the amount of raw materials;

[0042] ④After the glass is melted, lower the temperature to 900-1000°C, pass high-purity oxygen to remove water, and provide an oxidizing atmosphere at the same time to prevent the bismuth oxide from being reduced. The ventilation time depends on the amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com