Alloy spring steel ultra-fine martensite heat treatment quenching strengthening process

A spring steel, ultra-fine technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems that the effect is not very significant, the improvement of performance indicators is limited, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

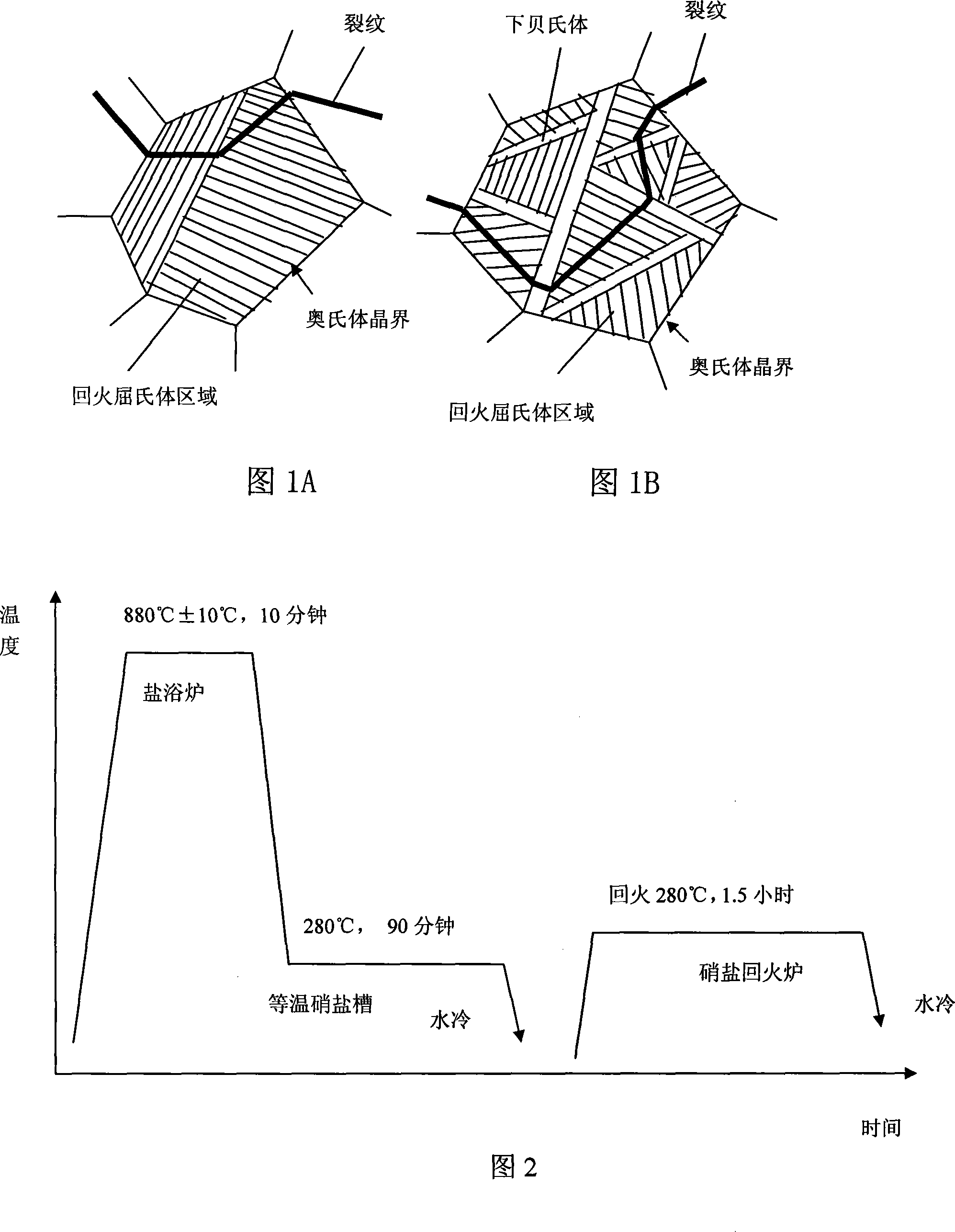

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and example the patent of the present invention is further described.

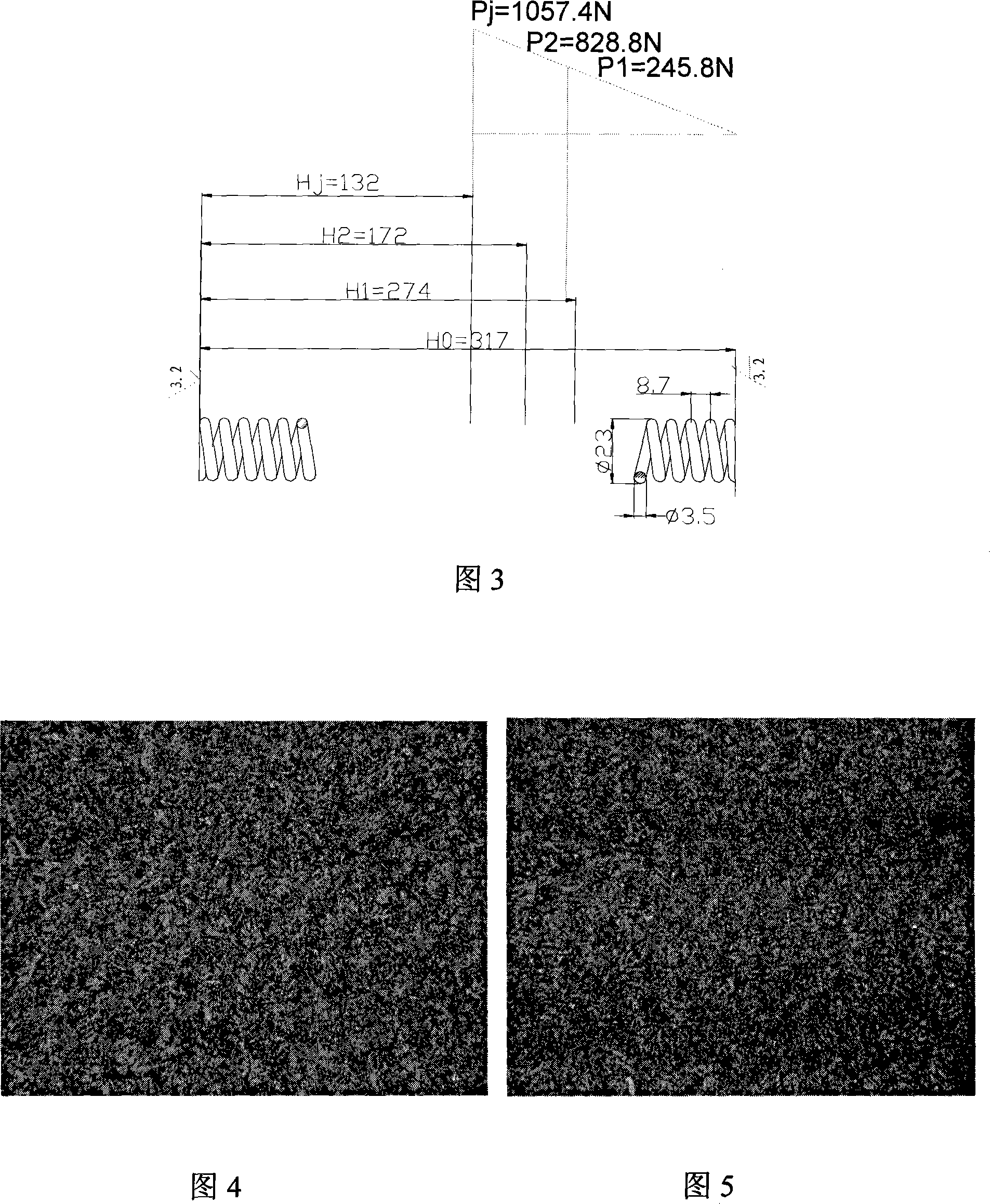

[0018] Take the processing of spring parts shown in Figure 3 as an example, spring material: 65Si 2 MnWA, technical requirements: cylindrical compression spring, direction of rotation: right-handed; effective number of turns: 36; total number of turns: 37.5; unfolded length: 2288 mm; heat treatment hardness: 51HRC-56HRC; surface treatment: dipping X98 after phosphating -1 two layers of glue (ZBG51071-1987); inspection: compression test for 24 hours H2 = 172mm, 790N≤P2≤890N; acceptance conditions according to II-WJ532-1993.

[0019] Combined with the process diagram 2, put the coiled spring into the core column and put it vertically into the salt bath furnace. The temperature of the salt bath furnace is controlled at 880°C, and the spring holding time is 10 minutes. In the salt tank, the temperature of the nitrate-salt tank is controlled at 280°C, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com