Steering knuckle non-quenched and tempered steel substituting 40Cr quenched and tempered steel and production method thereof

A non-quenched and tempered steel and steering knuckle technology, which is applied in the field of non-quenched and tempered steel for high-strength and toughness steering knuckles and non-quenched and tempered steel for steering knuckles, can solve the problem that the machining accuracy and assembly accuracy of parts cannot be guaranteed, and the parts The problems of uneven section performance and complex shape of the steering knuckle can achieve the effect of excellent assembly accuracy, avoiding quenching and tempering heat treatment, and eliminating the need for straightening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

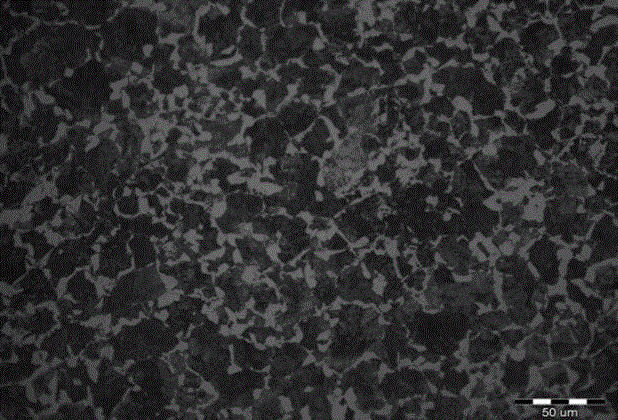

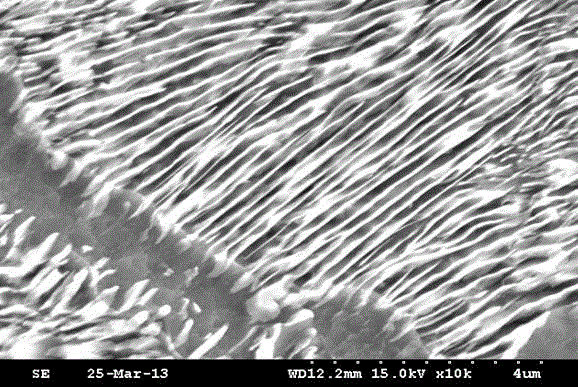

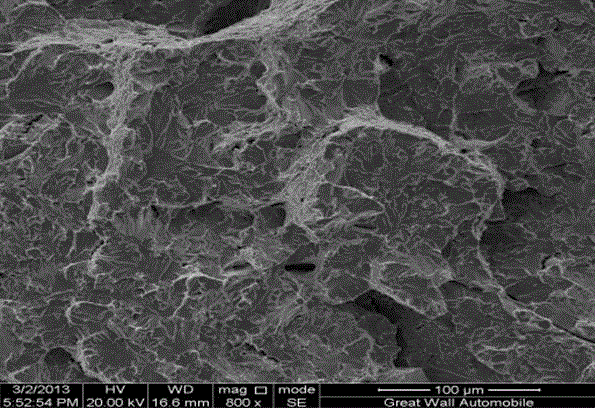

Image

Examples

Embodiment 1

[0081] Non-quenched and tempered steel for steering knuckle instead of 40Cr quenched and tempered steel, which includes the following components according to weight percentage (%): C: 0.38, Si: 0.60, Mn: 1.25, P: 0.010, S: 0.040, Cu: ≤0.20, Cr: 0.25, Mo: 0.02, Al: 0.010, V: 0.15, Nb: 0.015, Ti: 0.010, N: 0.017, [H] is 1.2 ppm, [O] is 9 ppm, and the rest is Fe.

[0082] A method for producing the above-mentioned non-quenched and tempered steel for steering knuckle instead of 40Cr quenched and tempered steel, comprising the following steps: hot metal desulfurization → LD → LF → RH → continuous casting → cutting → cooling → inspection → determination → heating in a heating furnace → control Rolling→cooling→ultrasonic+magnetic flux leakage inspection→judgment→packaging→weighing→storage.

[0083] When LD high-purity steel is refined, the content of Mn in LF smelting is targeted at 1.25%, and is controlled within the range of 1.20%-1.30%. When RH is hoisted, S wire is fed to the tar...

Embodiment 2

[0094] Non-quenched and tempered steel for steering knuckle instead of 40Cr quenched and tempered steel, which includes the following components according to weight percentage (%): C: 0.39, Si: 0.62, Mn: 1.23, P: 0.008, S: 0.045, Cu: ≤0.20, Cr: 0.24, Mo: 0.01, Al: 0.012, V: 0.14, Nb: 0.016, Ti: 0.012, N: 0.016, [H] is 1.0 ppm, [O] is 10 ppm, and the rest is original Fe.

[0095] The method for producing the above-mentioned non-quenched and tempered steel for steering knuckle instead of 40Cr quenched and tempered steel comprises the following steps: hot metal desulfurization→LD→LF→RH→continuous casting→cutting→cooling→inspection→judgment→heating in a heating furnace→controlled rolling→ Cooling→ultrasonic+magnetic flux leakage testing→judgment→packaging→weighing→storage.

[0096] When LD high-purity steel is refined, the content of Mn in LF smelting is targeted at 1.23%, and is controlled within the range of 1.20%-1.30%. When RH is hoisted, the S wire is fed to the target value ...

Embodiment 3

[0107] Non-quenched and tempered steel for steering knuckle instead of 40Cr quenched and tempered steel, which includes the following components according to weight percentage (%): C: 0.37, Si: 0.65, Mn: 1.26, P: 0.009, S: 0.042, Cu: ≤0.20, Cr: 0.27, Mo: 0.02, Al: 0.008, V: 0.17, Nb: 0.017, Ti: 0.008, N: 0.016, [H] is 1.5 ppm, [O] is 11 ppm, and the rest is original Fe.

[0108] The method for producing the above-mentioned non-quenched and tempered steel for steering knuckle instead of 40Cr quenched and tempered steel comprises the following steps: hot metal desulfurization→LD→LF→RH→continuous casting→cutting→cooling→inspection→judgment→heating in a heating furnace→controlled rolling→ Cooling→ultrasonic+magnetic flux leakage testing→judgment→packaging→weighing→storage.

[0109]When LD high-purity steel is refined, the content of Mn in LF smelting is targeted at 1.26%, and is controlled within the range of 1.20%-1.30%. When RH is hoisted, the S wire is fed to the target value a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com