Heat treatment method for tools

A heat treatment furnace and tool technology, applied in the field of heat treatment, can solve the problems of increasing expenses, breaking of hand tools, increasing the hardness of hand tool materials, etc., and achieve the effect of eliminating straightening and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

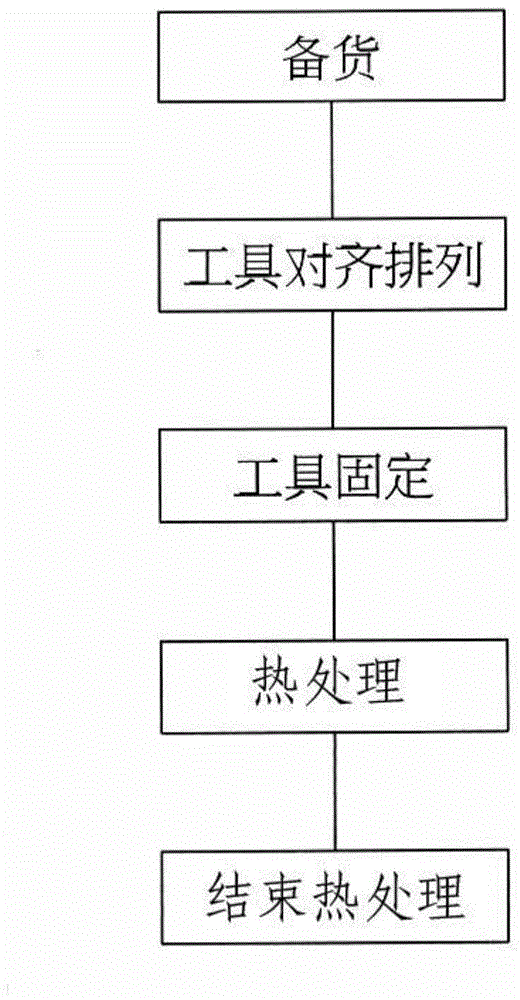

[0036] Please refer to Figure 1 to Figure 2 , which is the first preferred embodiment of the present invention, for achieving the above object, it comprises the following steps:

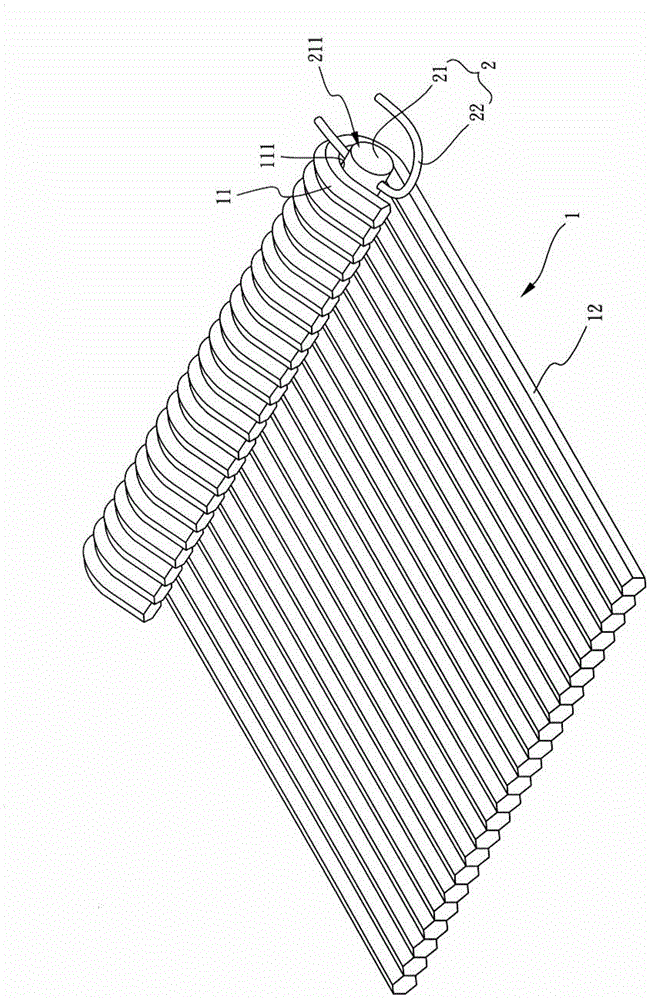

[0037] Stocking up: select several tools 1 to be heat treated, each of which includes a joint portion 11 with a perforation 111 and a working portion 12;

[0038] Fixing of the tool 1 to be heat treated: prepare a fixing rod 2, the fixing rod 2 includes a rod part 21 and two stoppers 22, each of the stoppers 22 is respectively installed in the two stoppers 211 at the two ends of the rod part 21 , use the rod portion 21 of the fixing rod 2 to pass through each of the through holes 111, so that the joints 11 are aligned, and use the stopper 22 to pass through the stopper 211 to tightly fix the heat treatment tools 1, so that The joints 11 are closely attached and contacted, fixed by the fixing rod 2 so that the tools 1 to be heat treated are supported against each other and assembled and fixed;

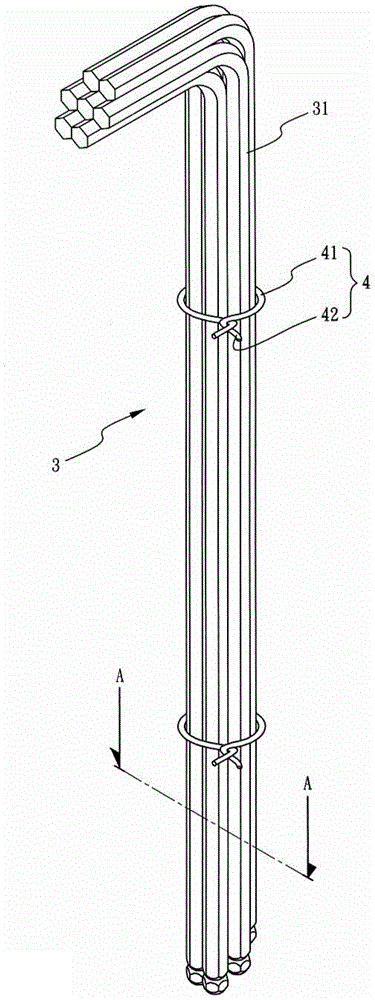

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com