Field welding tool for traveling I-shaped beam and assembling and welding method of field welding tool

An I-shaped beam and on-site welding technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of easy deformation of the flange plate, reduce welding deformation, save costs, and be easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing:

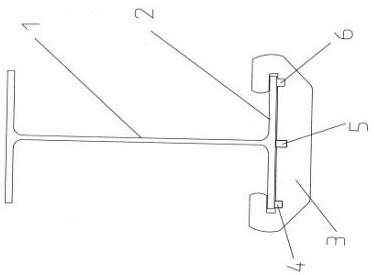

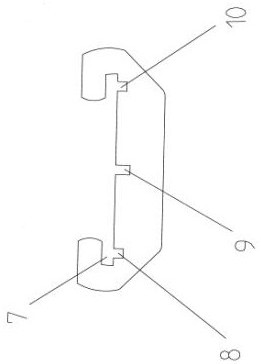

[0022] An on-site welding tool for traveling I-shaped beams in a steam turbine house, including a web 1, a lower flange 2 and an upper flange, the web 1, the lower flange 2 and the upper flange are connected by spot welding For an I-shaped beam, an anti-deformation fixture plate 3 is sleeved on the lower flange plate 2, and an inverted T-shaped groove 7 is arranged on the top surface of the anti-deformation fixture plate 3. Left positioning wedge embedded groove 8, middle positioning wedge embedded groove 9 and right positioned wedge embedded groove 10 are respectively provided on the groove bottom surface of the groove, and left positioning wedge embedded groove 8 is provided with left positioning wedge Block 4, the upper top surface of the left positioning wedge block 4 is connected to the lower bottom surface of the lower flange plate 2, and the middle positioning wedge blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com