Cold-rolled steel sheet with high yield ratio and excellent weather resistance

A cold-rolled steel sheet and high yield-strength ratio technology, applied in the field of high-strength cold-rolled steel sheet and its manufacturing, can solve the problems of cold-rolled steel product center segregation, damage workability, etc., achieve high yield-strength ratio, save energy, The effect of improving annealing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0045] The cold-rolled steel sheet of the invention has both high strength and high yield ratio. According to an exemplary embodiment of the present invention, the steel plate has a tensile strength of at least 80 kg / mm 2 , such as 80-110kg / mm 2 . The steel plate has a yield strength of at least 80%, such as 85% to 94%. In addition, the steel plate has a ductility of at least 10%.

[0046] These characteristics meet the requirements of the above-mentioned composition system and can be obtained by the low temperature annealing of the present invention. The low temperature annealing may partially retain the deformed grains in the microstructure, rather than fully recovering them. The microstructure of the present invention may be ferrite or a mixture of ferrite and pearlite, but is not limited thereto.

[0047] Hereinafter, a method of manufacturing a cold-rolled steel sheet will be described.

[0048] A method of manufacturing a steel material having the above composition...

Embodiment 1

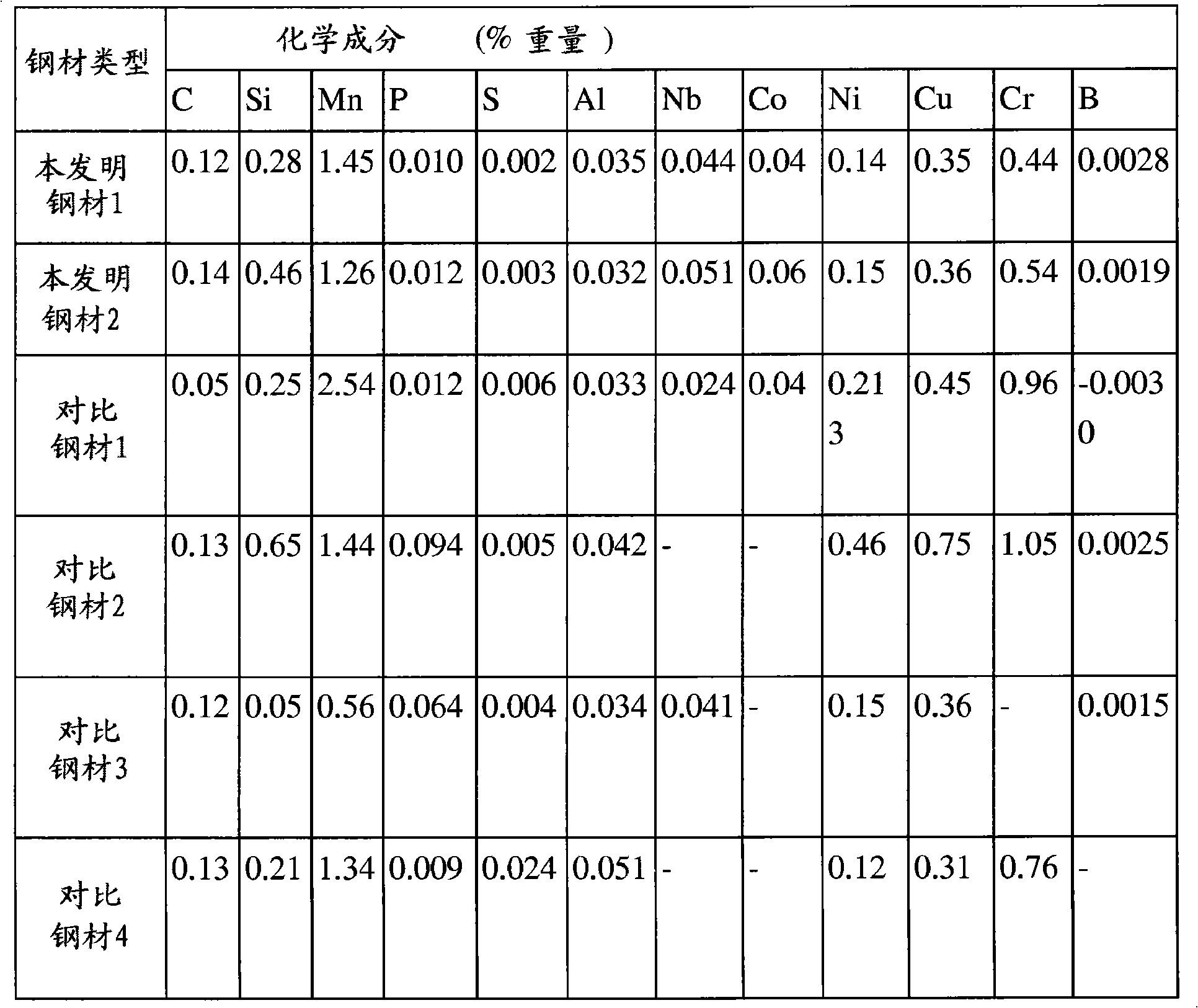

[0060] The normalized corrosion index (CI) and weather resistance of steel materials having the compositions shown in Table 1 were measured. The results are shown in Table 2.

[0061] In the weather resistance test, the steel material was subjected to a salt spray test (SST) at 30° C. for 480 hours with 5% salt water (NaCl solution). Here, the corrosion resistance index (CI) is an index for estimating weather resistance according to ASTM G101. The higher the corrosion resistance index, the stronger the weather resistance.

[0062] The corrosion resistance index is mainly obtained based on alloying elements, and satisfies the following formula.

[0063] Corrosion resistance index (CI)≤26.01(%Cu)+3.88(%Ni)+1.2(%Cr)+1.49(%Si)+17.28(%P)-7.29(%Cu)(%Ni)-9.10(% Ni)(%P)-33.39(%Cu) 2

[0064] Table 1

[0065]

[0066] Table 2

[0067] steel type

Corrosion Index (CI)

Corrosion level (weight loss,

g / cm 2 )

Weather resistance evaluation

...

Embodiment 2

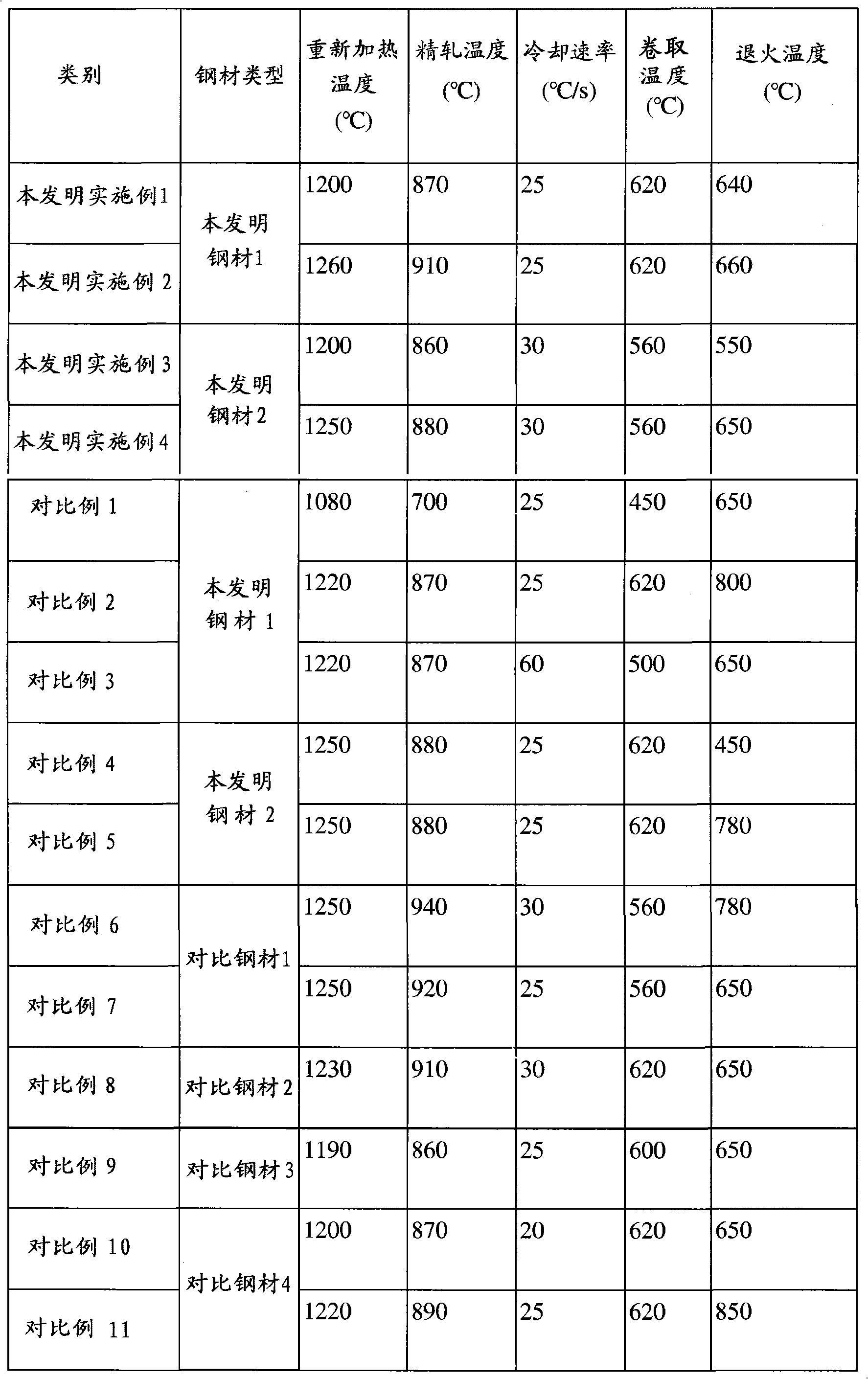

[0071] Each of the steel materials, that is, the inventive steel materials 1 and 2 and the comparative steel materials 1-4 in Table 1 of Example 1, was used to manufacture cold-rolled steel sheets under the conditions described in Table 3. The mechanical properties and workability properties of each steel sheet were measured, and the results are shown in Table 4.

[0072] table 3

[0073]

[0074] Table 4

[0075]

category

Yield Strength

(kgf / mm 2 )

tensile strength

(kgf / mm 2 )

Elongation

(%)

(%)

Bending workability

Embodiment 1 of the present invention

84.9

90.4

11

93.9

excellent

Embodiment 2 of the present invention

82.1

92.4

13

88.9

excellent

Embodiment 3 of the present invention

86.3

101.0

10

85.4

exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com