V microalloying high-toughness bainite non-quenched and tempered steel and controlled forging and controlled cooling technology and production technology thereof

A high-strength toughness, micro-alloying technology, applied in the field of alloy structural steel, can solve the problems of reducing the fatigue performance of bainite non-quenched and tempered steel, difficulty in the precipitation of carbides for pinning dislocations, and low strength of non-quenched and tempered steel. Achieve the effect of improving plastic toughness and yield strength ratio, reducing movable dislocation density and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with examples.

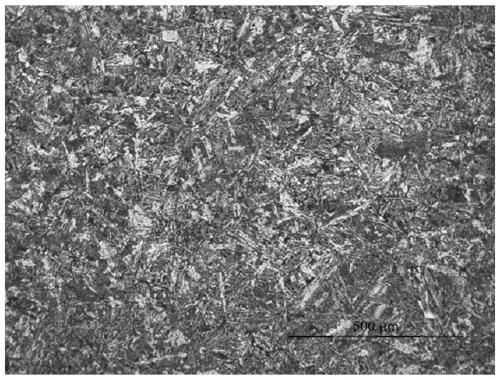

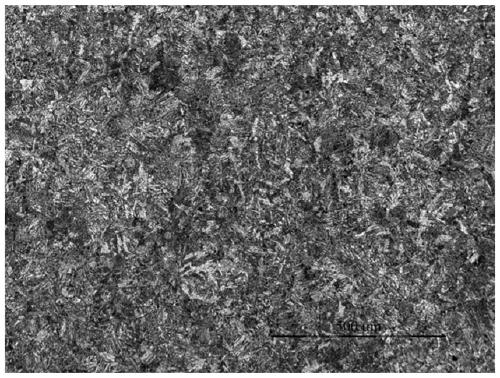

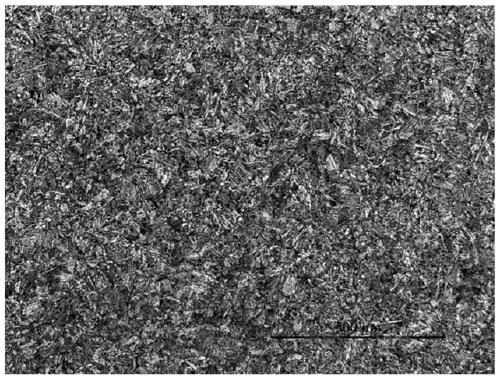

[0041] Among them, Comparative Examples 1-3 adopt the steel composition in Example 1, but do not adopt the controlled forging and controlled cooling process of the present invention, and the traditional steel in the table below is 42CrMo quenched and tempered steel.

[0042] The high-strength toughness bainite type non-quenched and tempered steel and the chemical composition weight percentage of the quenched and tempered steel 42CrMo of the automobile front axle of embodiment 1-3 are as shown in table 1, and embodiment 1-3 and traditional steel all adopt electric furnace smelting, through LF Continuous casting after refining + RH vacuum degassing The round billet, the round billet is made by heating and rolling Round steel, after the round steel is blanked, heated by an intermediate frequency induction furnace, rolled forged, die forged, and edge trimmed, the controlled cooling li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com