Process for producing screw-thread steel by draw-milling

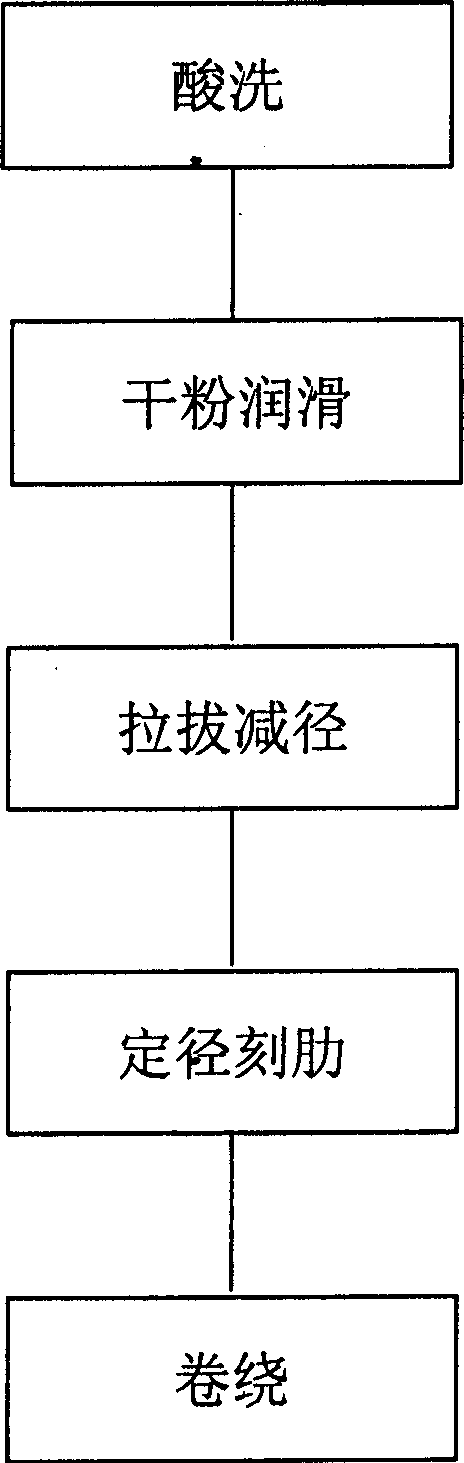

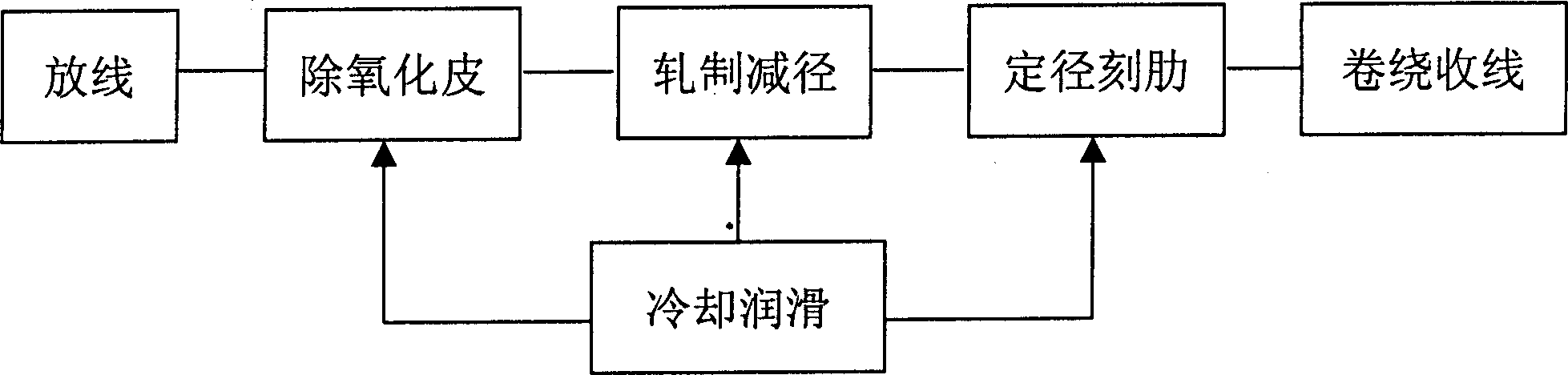

A production process, the technology of spiral ribs, applied in the field of production process of spiral rib steel bars by rolling method, can solve the problems of affecting the working conditions of operators, the large internal stress of spiral rib steel bars, and the difficulty in ensuring product quality, so as to avoid acid Washing process, reduce mold loss and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

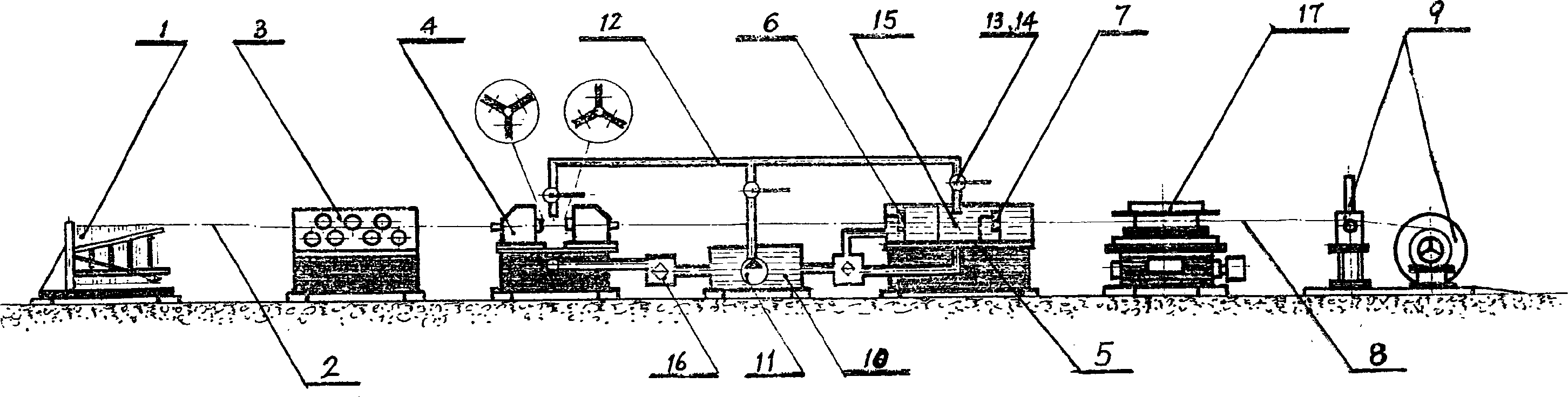

[0032] The process and device of the present invention are used to produce WCD-H cold-rolled spiral steel bars (ie, female threaded steel bars) with a diameter of 10 mm.

[0033] The Q235 hot-rolled circular wire rod 2 of Φ14mm is used as the raw material, the wire rod is placed on the pay-off frame 1, and the head of the wire rod is introduced into the rolling multi-roller descaling device 3. The descaling device in this embodiment is designed as three Roller group, the first group of rollers has 5 upper and lower rollers, namely 2 upper rollers and 3 lower rollers; the second group of rollers has 7 left and right rollers, namely left 3 and right 4; the third group of rollers has 3 rollers Up and down rollers, namely up 2 down 1. The wire rod passes through the impact and friction on the surface of the rollers, and moves forward in a serpentine shape, that is, the kink motion between the rollers can peel off the surface oxide scale. .

[0034] The wire rod with the surface ...

Embodiment 2

[0037] The WLR-H cold drawn spiral rib steel wire of Φ6mm is produced by the process and device of the present invention.

[0038] Using Φ10mm grade 82MnA hot-rolled wire rod 2 as the raw material, the wire rod is placed on the pay-off frame 1, and its head is introduced into the rolling multi-roller descaling device 3. The descaling device in this embodiment is designed with two sets of rollers. The first set of rollers has 7 upper and lower rollers, namely 3 upper and 4 lower rollers; the second set of rollers has 5 left and right rollers, namely left 3 and right 2. Through the impact and friction on the surface of the rollers, and the twisting movement between the rollers up and down, left and right, the oxide skin on the surface of the wire rod can be peeled off cleanly, and the peeled oxide skin is immediately washed away by the lubricating liquid sprayed by the nozzle 14. .

[0039] The descaled wire rod then enters the Y-type three-roller 4 for rolling reduction. Y-ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com