Cold-rolled steel sheet with yield strength of 980 MPa grade and manufacturing method thereof

A yield strength, cold-rolled steel plate technology, used in bell-type furnaces, lighting and heating equipment, etc., can solve the problems of difficulty in achieving stable control and increase in cost, and achieve low cost, low annealing temperature, and high technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

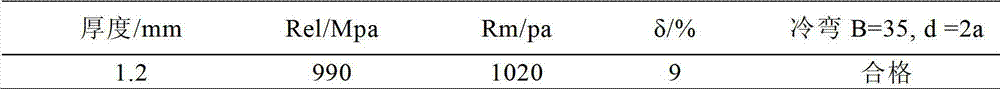

[0061] The chemical composition of the cold-rolled steel plate designed in this embodiment is by weight percentage: C: 0.09%, Si: 0.25%, Mn: 1.9%, Nb: 0.035%; Ti: 0.15%; Cr: 0.8%; P: 0.008% ;S: 0.001%; N: 0.0051%; O: 0.0038%; Alt: 0.036%; the rest are iron Fe and unavoidable impurities. According to the above composition design, the raw materials are smelted on a 120-ton converter, and alloyed with Nb, Ti, and Cr during the refining process, and then continuously cast into a continuous casting slab of 175mm×1210mm×11800mm, and the continuous casting slab is heated to 1250°C , the heating time is 160 minutes, rolled on a hot continuous rolling mill, the rough rolling start temperature is controlled at 1150°C, the rough rolling finish rolling temperature is controlled at 1050°C, the rough rolling is 5 passes, the thickness of the intermediate billet is 30mm, and the finish rolling is started. The temperature is controlled at 1020°C, the finish rolling temperature is controlled...

Embodiment 2

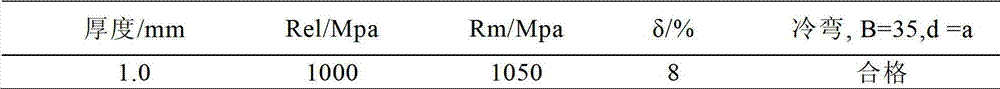

[0066] The chemical composition of the cold-rolled steel plate designed in this embodiment is: C: 0.1%, Si: 0.28%, Mn: 1.8%, Nb: 0.06%; Ti: 0.14%; Cr: 1.0%; P: 0.009% ; S: 0.003%; N: 0.0045%; O: 0.0036%; Alt: 0.032%; the rest are iron Fe and unavoidable impurities.

[0067] According to the above composition design, the raw materials are smelted on a 120-ton converter, and alloyed with Nb, Ti, and Cr during the refining process, and then continuously cast into a continuous casting slab of 175mm×1230mm×11800mm, and the continuous casting slab is heated to 1260°C , the heating time is 172 minutes, the rough rolling start temperature is controlled at 1190°C, the rough rolling finish temperature is controlled at 1040°C, the rough rolling is carried out for 5 passes, and the thickness of the intermediate billet is 35mm. The control is 1000°C, the finish rolling temperature is controlled at 850°C, 5 passes of finish rolling, the average reduction of each pass of finish rolling is co...

Embodiment 3

[0072] The chemical composition of the cold-rolled steel plate designed in this embodiment is: C: 0.09%, Si: 0.18%, Mn: 1.85%, Nb: 0.055%; Ti: 0.16%; Cr: 0.9%; P: 0.01% ; S: 0.004%; N: 0.0041%; O: 0.0033%; Alt: 0.030%; the rest are iron Fe and unavoidable impurities.

[0073] According to the above composition design, the raw materials are smelted on a 120-ton converter, and alloyed with Nb, Ti, and Cr during the refining process, and then continuously cast into a continuous casting slab of 175mm×1230mm×11800mm, and the continuous casting slab is heated to 1270°C , the heating time is 165 minutes, the rough rolling start temperature is controlled at 1180°C, the rough rolling finish temperature is controlled at 1040°C, the rough rolling is carried out for 5 passes, and the thickness of the intermediate billet is 33mm. The control is 1000°C, the finish rolling temperature is controlled at 850°C, there are 5 passes of finish rolling, the average reduction of each pass of finish r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com