Al-Mg-Si aluminum alloy material, aluminum alloy plate, and preparation methods of Al-Mg-Si aluminum alloy material and aluminum alloy plate

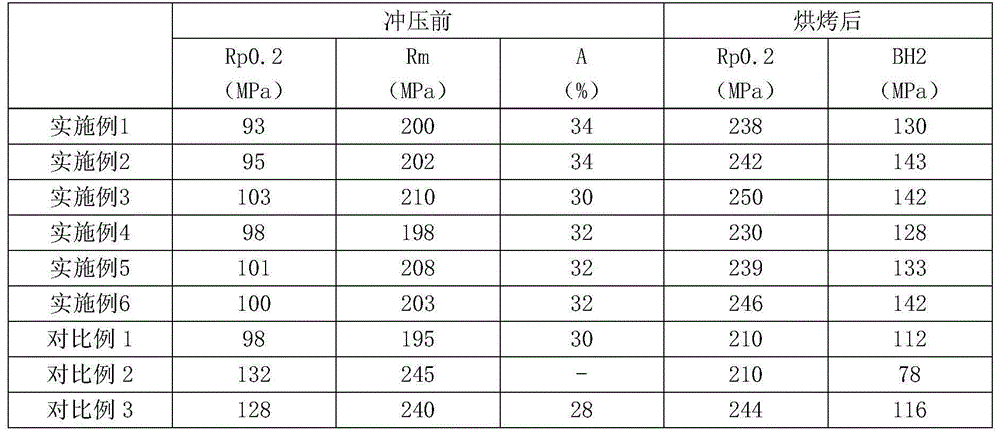

A technology of aluminum alloy material and aluminum alloy plate, applied in the field of aluminum alloy material, can solve the problems of increasing cost, slow baking response rate, affecting the corrosion resistance of aluminum plate, etc., and achieve the effect of excellent formability and good baking hardening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

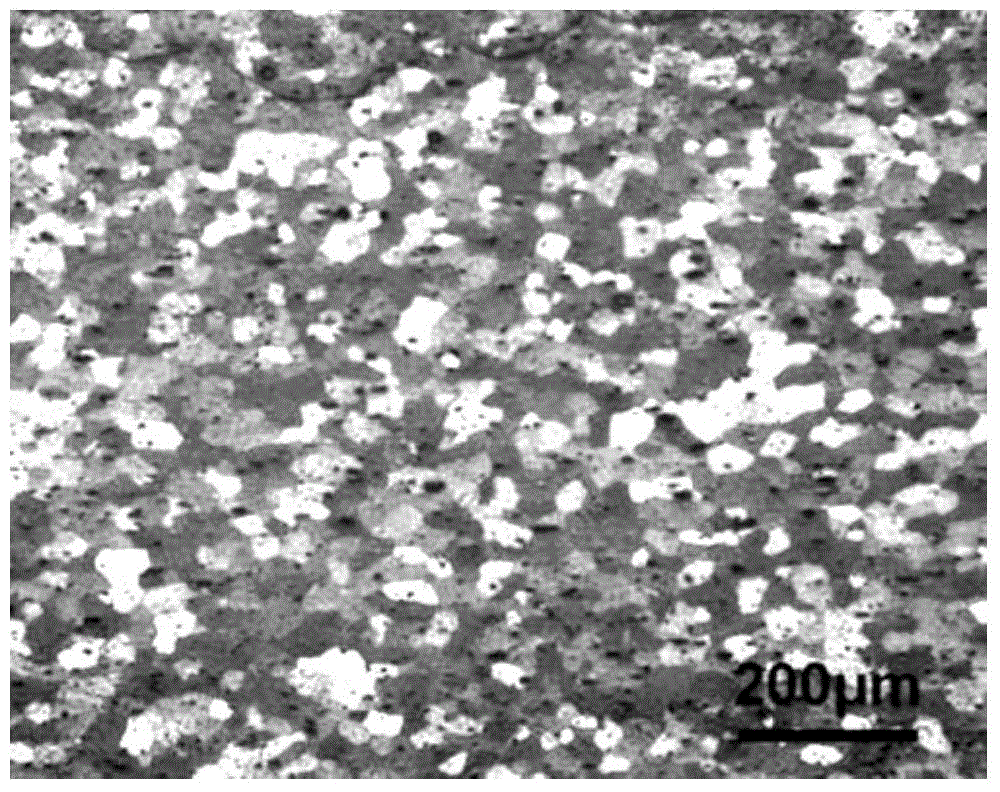

Image

Examples

Embodiment Construction

[0042] The AlMgSi series aluminum alloy material, aluminum alloy plate and its manufacturing method described in the present invention will be further explained and illustrated in conjunction with the accompanying drawings and specific examples. However, such explanations and illustrations do not constitute the technical solution of the present invention. Improperly qualified.

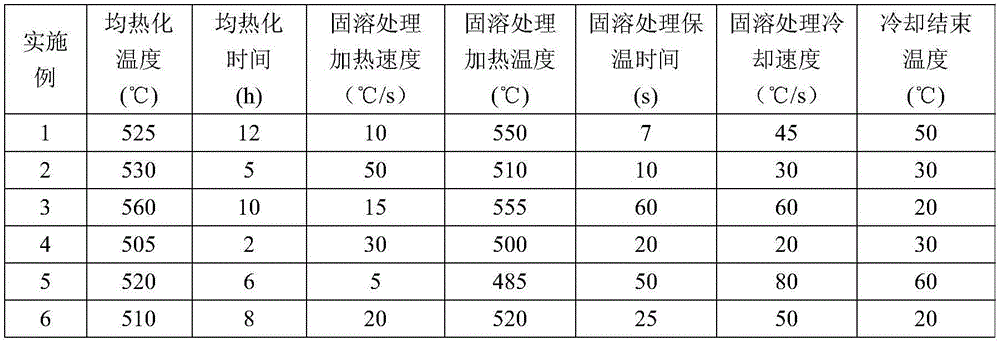

[0043] The aluminum alloy plates in Examples 1-6 were manufactured according to the long flow process (the mass percentage content of each chemical element of the aluminum alloy plates in Examples 1-6 is shown in Table 1):

[0044] (1) Melting;

[0045] (2) Casting: casting alloy billet by semi-continuous casting method (Direct chill caster), the thickness of the billet is 500mm, and the width is 1800mm;

[0046] (3) Face milling: the cutting depth reaches 10mm;

[0047] (4) Carry out homogenization heat treatment in a walking furnace: the heat treatment temperature is 500-580°C, and the heat treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com