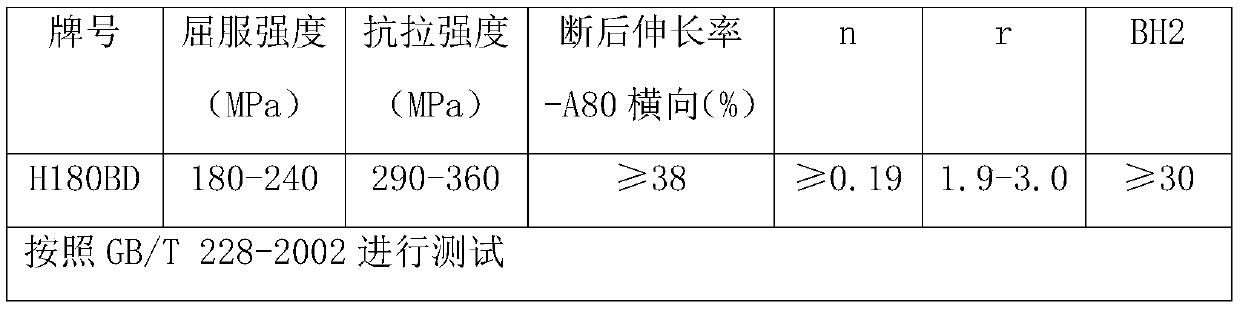

Hot-dip galvanized steel sheet with stable bake hardening performance and production method thereof

A hot-dip galvanized steel sheet, bake-hardening technology, applied in the field of metallurgy, can solve problems such as poor dent resistance, low yield strength, and wide-ranging application restrictions, and achieve good overall performance, excellent coating performance, and increased strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

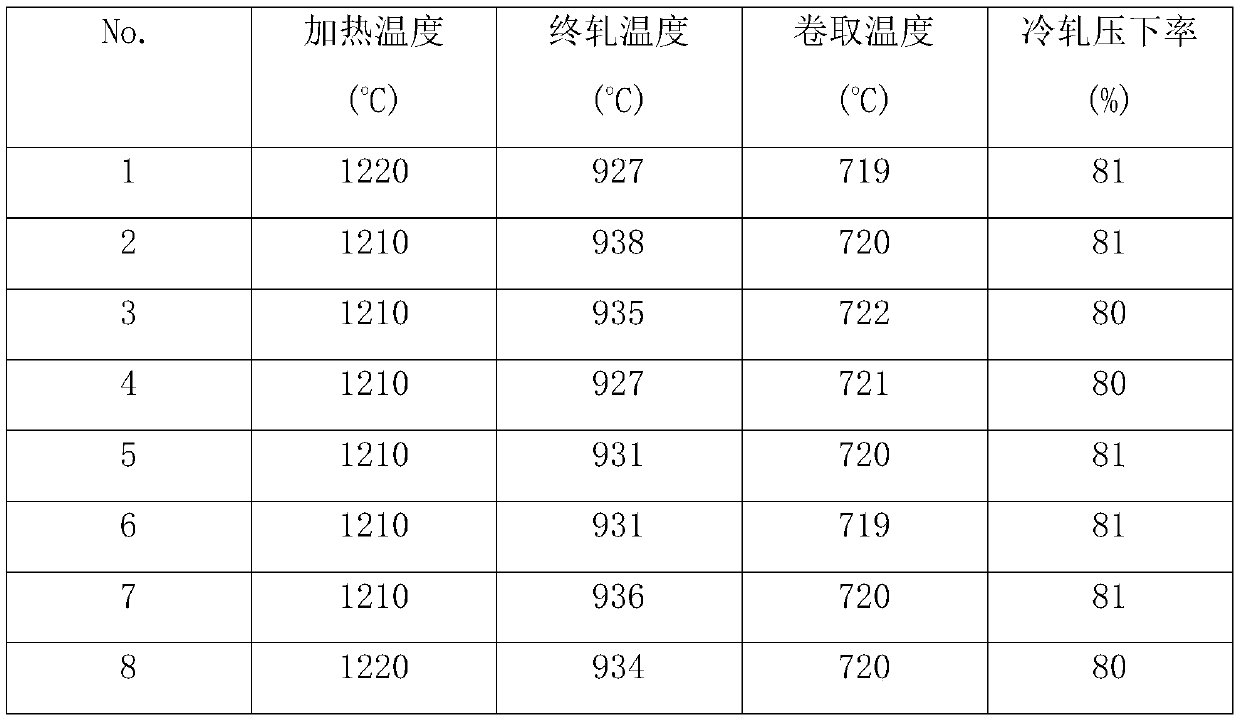

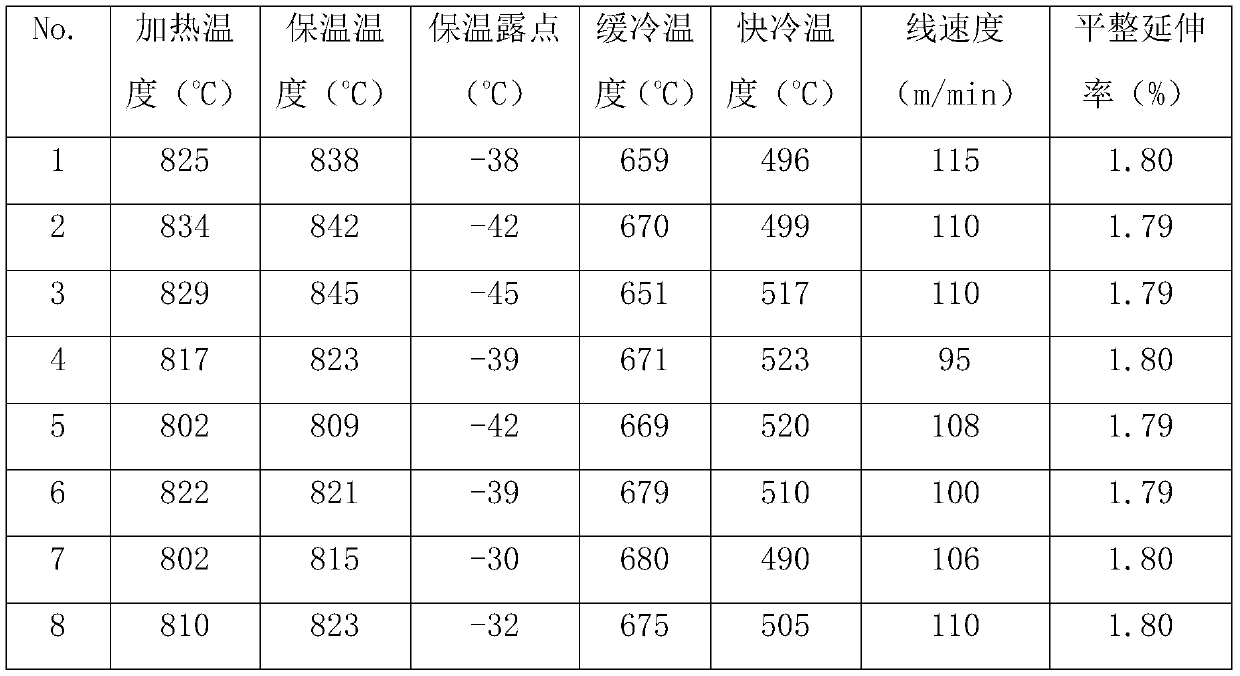

[0027] Below in conjunction with embodiment the present invention is further described:

[0028] The following examples describe the present invention in detail. These examples are only to describe the best embodiment of the present invention, and do not limit the scope of the present invention.

[0029] A hot-dip galvanized steel sheet with stable bake-hardening performance, its chemical composition design includes:

[0030] C: 0.0018% to 0.0033%; Si: ≤0.02%; Mn: 0.22% to 0.30%; P: 0.015% to 0.025%; S: ≤0.01; Ti: 0.002% to 0.01%; ; Als: 0.04% ~ 0.06%; N: ≤ 0.003%; solid solution C: 0.0005% -0.0015%, the balance of iron and unavoidable impurities.

[0031] The ultra-low carbon and ultra-low nitrogen design provides good ductility and deep drawability, while the amount of alloying elements required to stabilize C and N is significantly reduced. In order to retain a certain amount of interstitial solid-solution carbon atoms to produce bake hardening, the content of C, N, Ti, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com