A processing method of an aluminum alloy strip that uses an end surface wrapped aluminum foil to suppress the color difference of the side surface

A technology of aluminum alloy strips and processing methods, which is applied in the field of processing aluminum alloy strips, can solve problems such as color difference of aluminum alloy strips, and achieve the effects of little impact on production efficiency, simple operation, and low difficulty in production control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

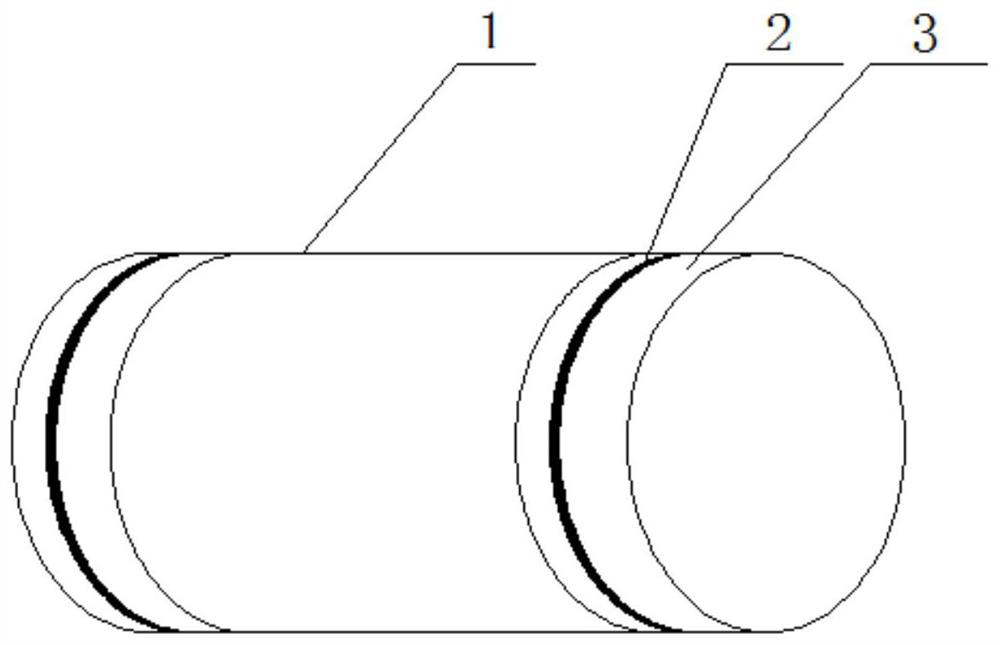

[0025] Specific Embodiment 1: In this embodiment, the processing method of the aluminum alloy strip that wraps the aluminum foil on the end surface to suppress the color difference on the side surface is carried out according to the following steps:

[0026] 1. Cold rolling:

[0027] Putting the aluminum alloy billet in a cold rolling mill for rolling, and standing still for 20-28 hours after rolling to obtain a semi-finished strip coil;

[0028] 2. Annealing:

[0029] The two end surfaces of the semi-finished strip coil obtained in step 1 are respectively wrapped with aluminum foil and bundled, and then transferred to an annealing furnace for annealing;

[0030] Three, secondary cold rolling:

[0031] Step 2: After annealing, remove the aluminum foils on the two end surfaces of the semi-finished strip coil, and then transfer the semi-finished strip coil to a cold rolling mill for secondary cold rolling to the thickness of the finished product to obtain the finished strip; ...

specific Embodiment approach 2

[0038] Embodiment 2: This embodiment is different from Embodiment 1 in that: the processing rate of the rolling described in step 1 is 70%-98%. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0039] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the thickness of the semi-finished strip in the semi-finished strip roll in step 1 is 0.19-2mm. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com