A production method of cold-rolled dual-phase steel substrate

A production method and technology of dual-phase steel, applied in metal rolling and other directions, can solve the problems of fluctuation in mechanical properties of the whole coil, difficulty in cold rolling and annealing, fluctuation in pass-length properties, etc. economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

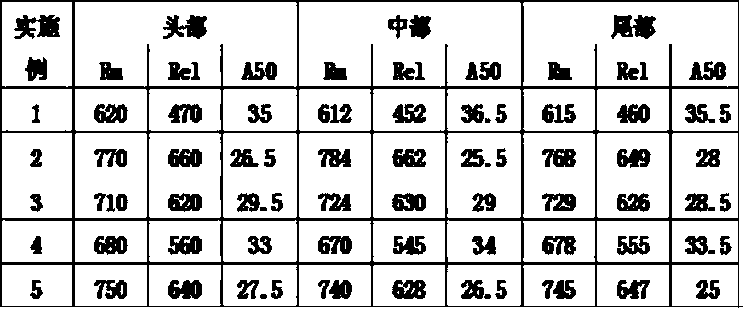

Examples

Embodiment 1

[0019] Embodiment 1: The specific process of the production method of the cold-rolled dual-phase steel substrate is as follows.

[0020] Steelmaking and casting steps: The weight percentage of the chemical composition of the molten steel is: C 0.15%, Mn 1.50%, S0.012%, P 0.025%, Si 0.25%, Cr 0.40%, Ti 0.015%, N 0.005%, and the rest For iron and unavoidable impurities, in the casting step, the superheating degree of molten steel is 30°C; with the application of dynamic light pressure, the fluctuation of the crystallizer liquid level is stably controlled within ±2mm.

[0021] Heating steps: first heating section temperature: 900-1000°C, second heating section temperature: 1100-1200°C, third heating section temperature: 1250-1300°C, soaking section temperature: 1230-1280°C, slab head-to-tail temperature difference ≤20 ℃.

[0022] Hot rolling step: control the start rolling temperature of the rough rolling of the slab at 1110±10°C; the start rolling temperature of the finish roll...

Embodiment 2

[0024] Embodiment 2: The specific process of the production method of the cold-rolled dual-phase steel substrate is as follows.

[0025] Steelmaking and casting steps: The weight percentage of the chemical composition of the molten steel is: C 0.19%, Mn 1.90%, S0.010%, P 0.012%, Si 0.5%, Cr 1.0%, Ti 0.055%, Nb 0.050%, N 0.005%, the rest is iron and unavoidable impurities. During the casting process, the superheated degree of molten steel is 25°C; under dynamic light pressure, the fluctuation of the mold liquid level is stably controlled within ±2mm.

[0026] Heating steps: temperature of the first heating section: 850-950°C, temperature of the second heating section: 1150-1220°C, temperature of the third heating section: 1280-1320°C, temperature of the soaking section: 1250-1300°C, temperature difference between the head and tail of the slab ≤20 ℃.

[0027] Hot rolling step: control the start rolling temperature of the rough rolling of the slab at 1120±10°C; the start rolling...

Embodiment 3

[0029] Embodiment 3: The specific process of the production method of the cold-rolled dual-phase steel substrate is as follows.

[0030] Steelmaking and casting steps: The weight percentage of the chemical composition of the molten steel is: C 0.17%, Mn 1.80%, S0.008%, P 0.010%, Si 0.3%, Cr 0.60%, Nb 0.035%, Ti 0.025%, N 0.007%, the rest is iron and unavoidable impurities. During the casting process, the superheated degree of molten steel is 35°C; under dynamic light pressure, the crystallizer liquid level fluctuation is stably controlled within ±2mm.

[0031] Heating steps: first heating section temperature: 850-950°C, second heating section temperature: 1120-1230°C, third heating section temperature: 1280-1320°C, soaking section temperature: 1240-1290°C, slab head-to-tail temperature difference ≤20 ℃.

[0032] Hot rolling step: control the start rolling temperature of the rough rolling of the slab at 1130±10°C; the start rolling temperature of the finish rolling is 1070±10°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com