Method for producing Q460-grade building steel with low yield ratio and high toughness under air cooling

A low yield ratio, construction steel technology, applied in the field of steel plates for building structures, can solve the problems of high cost and high steel yield, and achieve the effects of good low temperature toughness, low yield ratio and stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

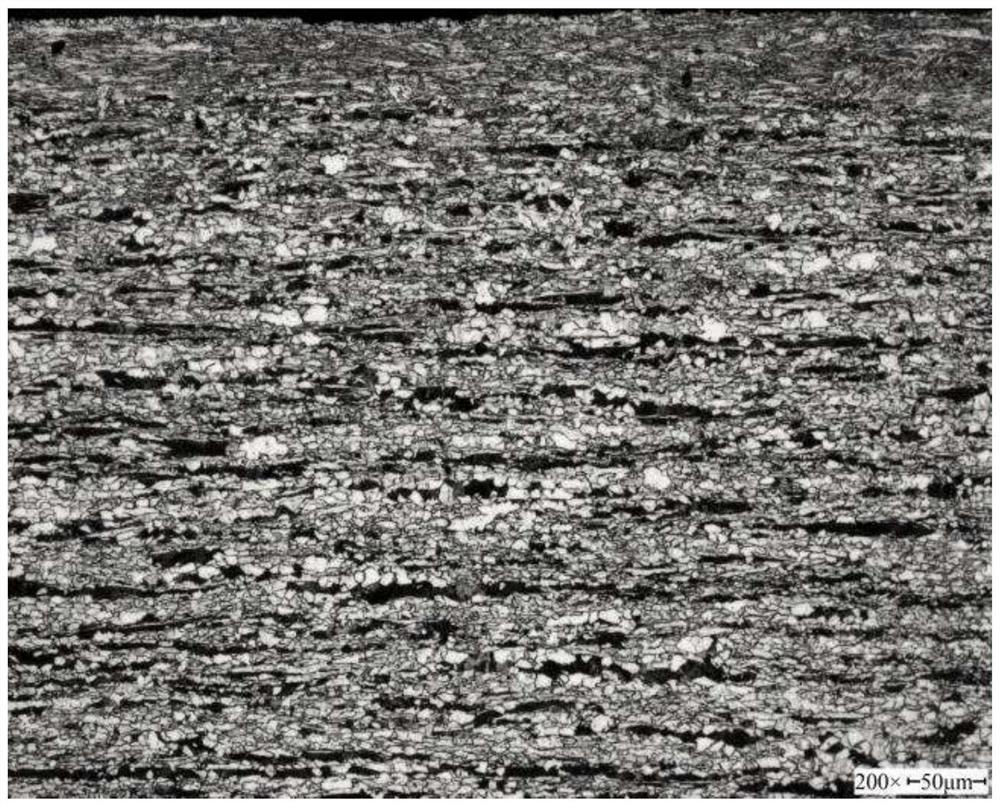

[0067] The metallographic structure of embodiment 1 is as Figure 1a and Figure 1b As shown, the metallographic structure of Example 1 is F+P+a small amount of B, the grain size of F at the edge is 9 to 14, the proportion of fine grains with a grain size of 14 on the surface is 78%, and the grain size of F at the center is 78%. Level 10;

Embodiment 2

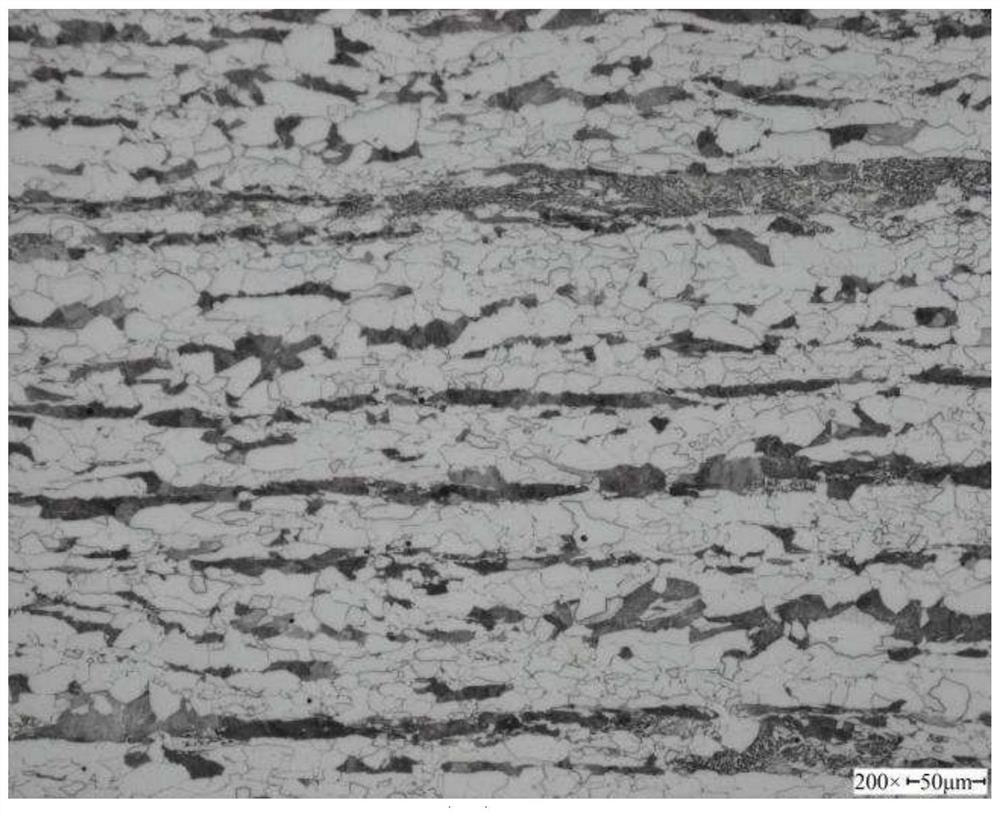

[0068] The metallographic structure of embodiment 2 is as Figure 2a and Figure 2b As shown, the metallographic structure of Example 2 is F+P, the F grain size of the edge is 9 to 13, the fine grain ratio of the surface grain size is 13 is 76%, and the F grain size of the center is 11 ;

[0069] The precipitate image of embodiment 2, energy spectrum result and size histogram are as follows Figure 2c , Figure 2d , Figure 2e , Figure 2f and Figure 2g As shown, the average size of the precipitates is 11.02nm, most of the precipitates are concentrated in the range of 0-10nm, and the volume percentage of the precipitates is 0.178%;

[0070] The K-T curve of embodiment 2 is as Figure 2h Shown, the ductile-brittle transition temperature T 50%FAT = -28.5°C;

Embodiment 3

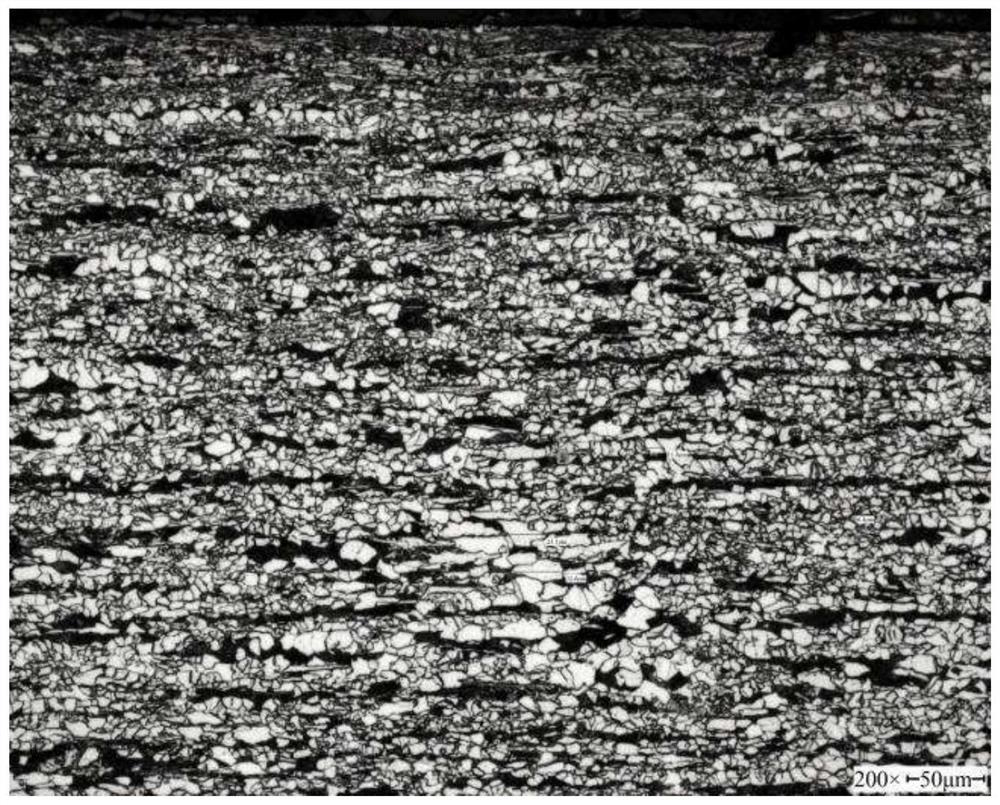

[0071] The metallographic structure of embodiment 3 is as Figure 3a and Figure 3b As shown, the metallographic structure of Example 3 is F+P+a small amount of B, the grain size of F at the edge is 9 to 14, the proportion of fine grains with a grain size of 14 on the surface is 82%, and the grain size of F at the center is 82%. Grade 11;

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com