Hot-dip galvanized ultra-low carbon bake-hardening steel and production method thereof

A baking hardening and production method technology, applied in the field of steel production, can solve the problems of automobile parts cracking, grain boundary fracture, steel plate secondary processing embrittlement, etc., and achieve considerable economic benefits, secondary processing brittleness and excellent comprehensive mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

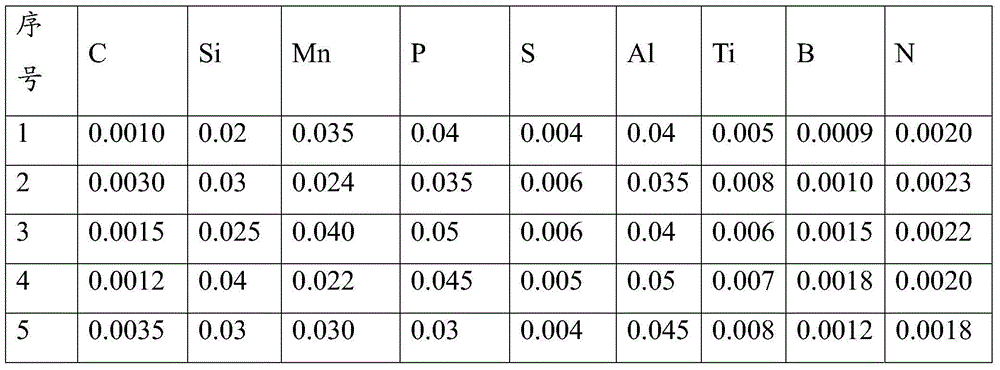

[0017] A hot-dip galvanized ultra-low-carbon bake-hardening steel provided in the embodiments of the present invention has the following chemical composition by weight percentage: C: 0.001-0.005%, Si: 0-0.12%, Mn: 0-1.0%, P: 0 to 0.50%, Al: 0.01 to 0.30%, Ti: 0.004 to 0.01%, B: 0.0003 to 0.0040%, limiting elements S≤0.010%, N≤0.01%, and the rest are Fe and unavoidable impurities.

[0018] In the present invention, the content of C element is controlled at 0.001-0.005%. Within this composition range, the steel plate can not only have excellent formability, but also provide sufficient excess C content, so that the steel plate has sufficient bake hardening value.

[0019] Mn exists in the steel in the form of solid solution or precipitation. In addition to the role of solid solution strengthening, it will also combine with S to prevent the steel plate from appearing red and brittle. If the Mn content is too low, the effect of strengthening and preventing the steel plate from bein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com