Clad automotive sheet product

A technology for cladding sheets and products, applied in the direction of layered products, metal layered products, transportation and packaging, etc., to achieve the effect of good curling performance and holding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

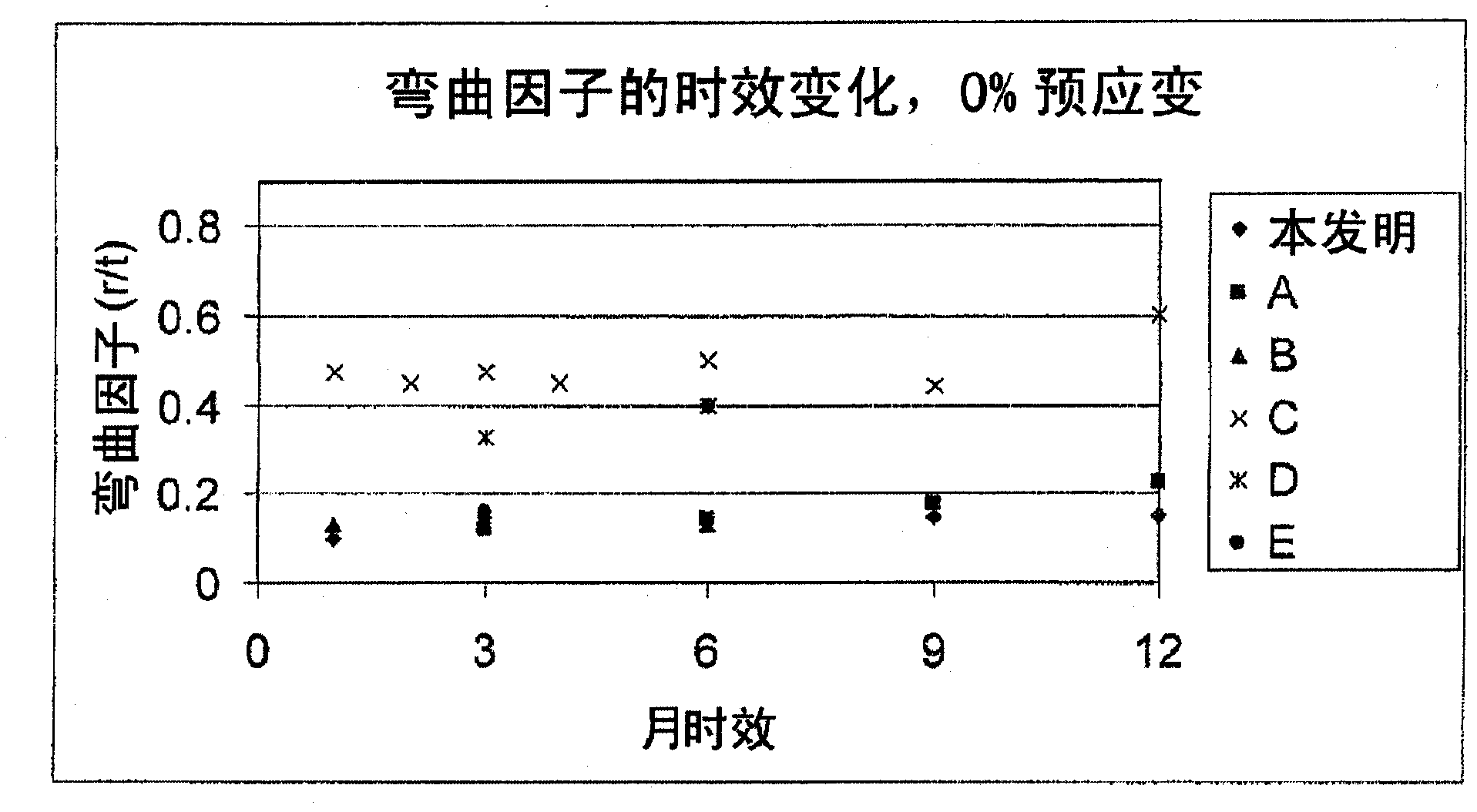

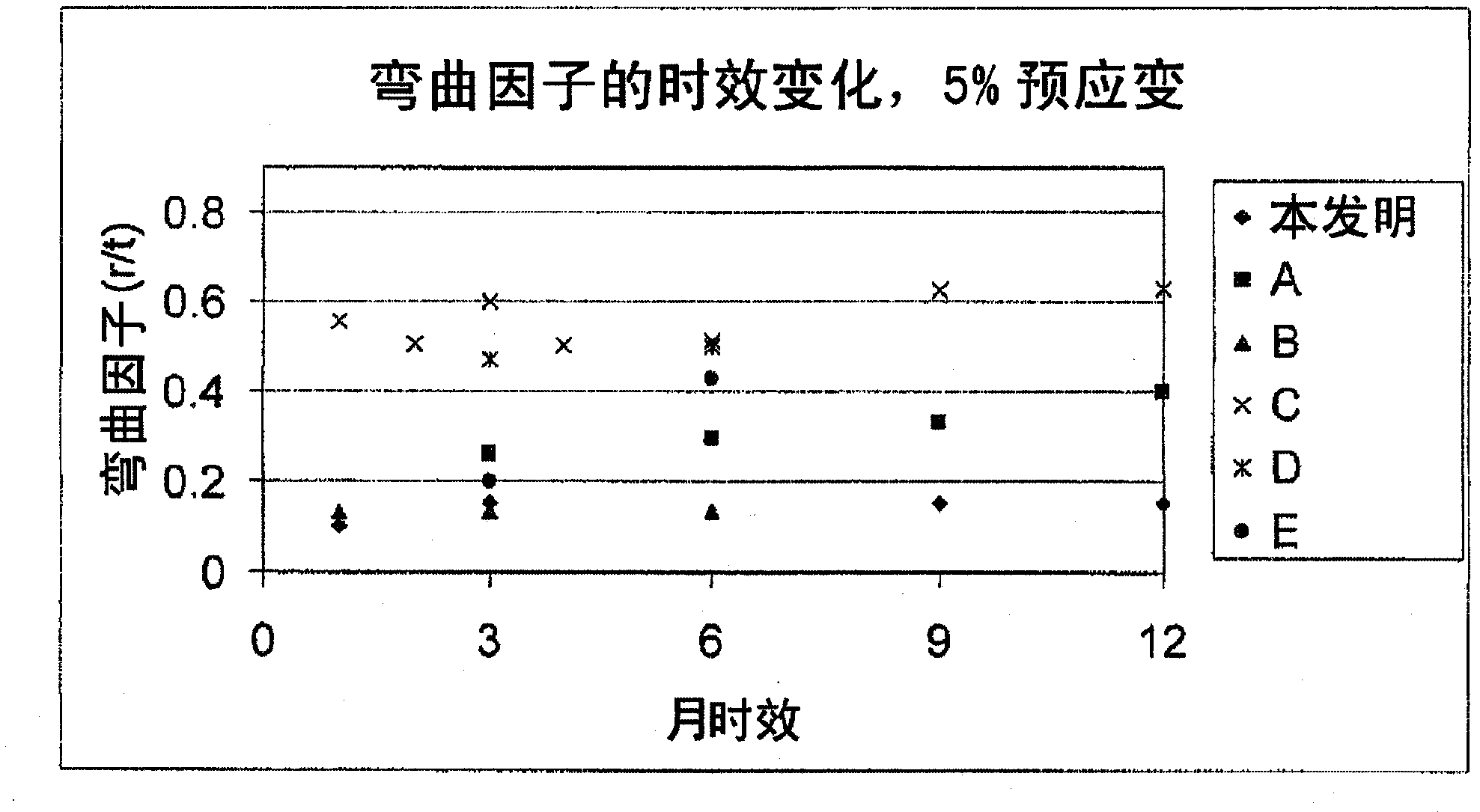

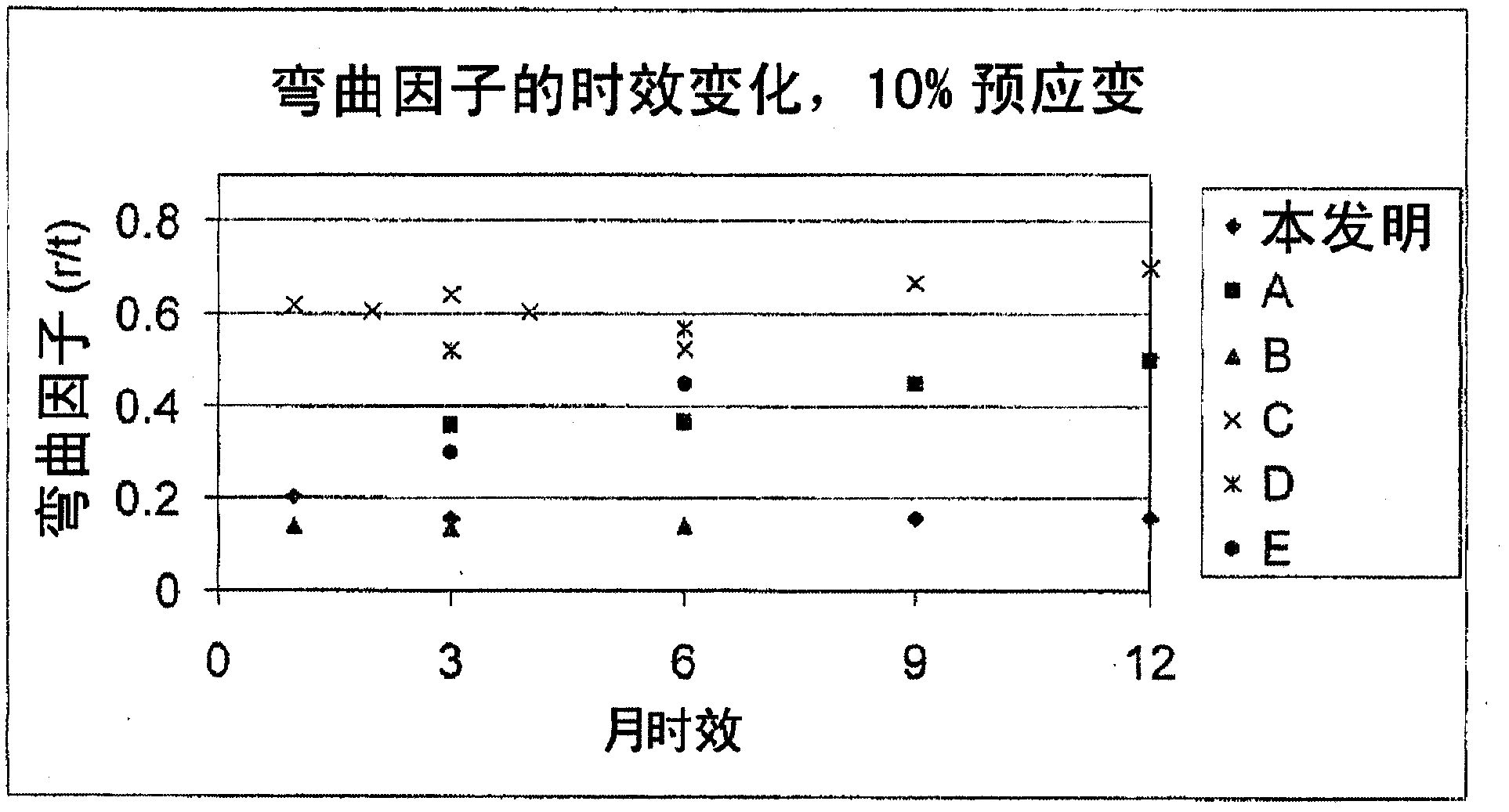

Examples

Embodiment

[0033] a) Sample preparation:

[0034] Composite ingots according to the invention were cast using the method described in WO04 / 112992. The composite ingot has two cladding layers of the same composition, one on each side of the core layer.

[0035] For comparison purposes, composite ingots were also cast using the casting method described in WO04 / 112992 to provide samples according to WO07 / 128391 and JP62-207642. In the case of the samples according to WO07 / 128391, the core layer is a 6016 alloy and the two cladding layers are low solute 6XXX series alloys. In the case of the sample according to JP62-207642, the core layer is also 6016 alloy, and the two cladding layers are of the same composition and are based on AA5005.

[0036] Furthermore, formulated monolithic automotive sheet alloys AC170, AA6016 and alloys according to EP1685268 are produced by conventional DC casting routes.

[0037] The chemical compositions of the samples tested are shown in Table 1.

[0038] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com