High volume edge and high baking hardening performance aluminum alloy sheet material and preparation method thereof

A technology of baking and hardening of aluminum alloy sheets, which is applied in the field of aluminum alloys, can solve the problems that mechanical properties and hemming properties cannot be taken into account at the same time, and achieve excellent surface quality and mechanical properties, high hemming and high hemming properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

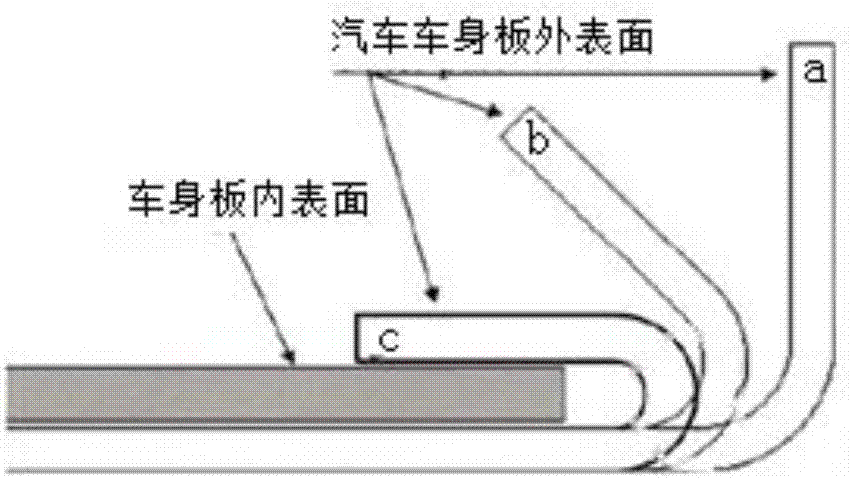

[0056] The steps of the aluminum alloy plate with high curling and high bake-hardenability for automobile body provided by the present invention and its preparation method are as follows:

[0057] Ingot:

[0058] Melt the following ratio (Si: 0.4~0.8, Mg: 0.4~1, Fe≤0.3, Cu≤0.2, Mn≤0.2, the balance is Al and normal impurities, and the total amount of impurities is less than 0.15wt.%, each Pure aluminum and various intermediate alloys with impurity element content less than 0.05wt.%, the melt is refined and cast into ingots by semi-continuous casting equipment.

[0059] The used semi-continuous casting equipment of the present invention can adopt Figure 5 The semi-continuous casting equipment shown or other existing casting equipment in the field. Such as Figure 5 As shown, the semi-continuous casting equipment includes a variable-frequency ultrasonic system and a semi-continuous casting system. The variable-frequency ultrasonic system includes a variable-frequency ultrason...

Embodiment 2

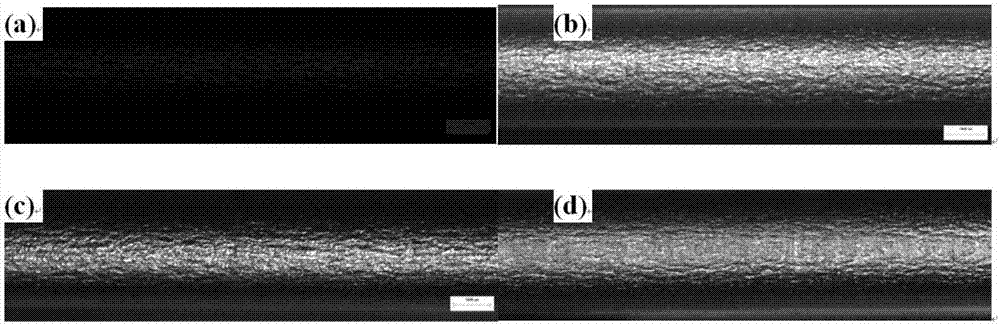

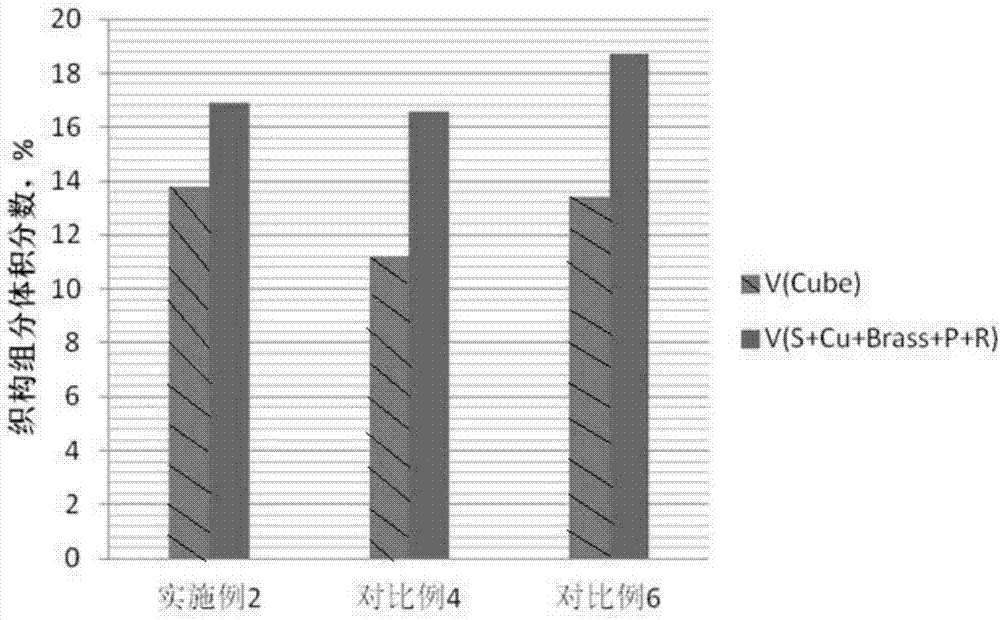

[0086] Embodiment 2, 5 and comparative example 1, 5 develop plate curling sample surface photo as figure 2 Shown; Embodiment 2 and comparative example 4 and 6 develop plate texture component volume fraction histogram as image 3 Shown; Embodiment 2 and comparative example 2 develop plate surface paint brush line photo as Figure 4 shown;

[0087] In the case of the same alloy composition and different preparation process parameters:

[0088] A. In Comparative Example 1, due to the low cold rolling rate after intermediate annealing, the grains of the trial-produced plate were coarse, the surface of the plate was rough after hemming, and the hemming performance did not meet the requirements;

[0089] B. In Comparative Example 2, due to the high cold-rolling rate after intermediate annealing, the paint brush line on the surface of the trial-produced plate is obvious, which does not meet the requirements;

[0090] C. In comparative example 3, due to the high intermediate annea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com