High strength cold rolled steel sheet and hot dip galvanized steel sheet having excellent formability and coating property, and the method for manufacturing thereof

A cold-rolled steel sheet and formability technology, applied to high-strength cold-rolled steel sheets with excellent formability and coating properties, can solve problems such as difficulties and high production costs, and achieve improved coating properties, excellent formability, and high tensile strength intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

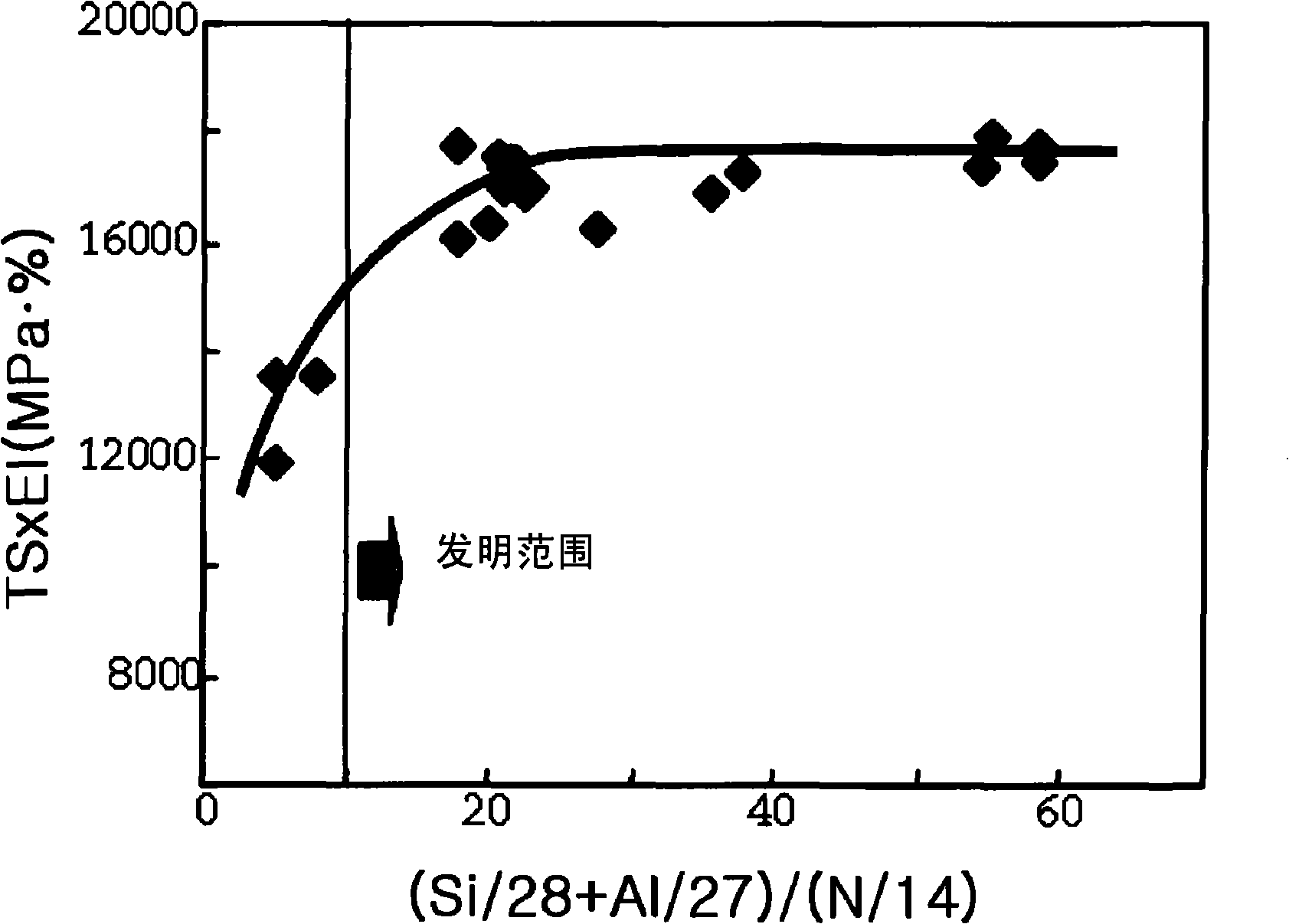

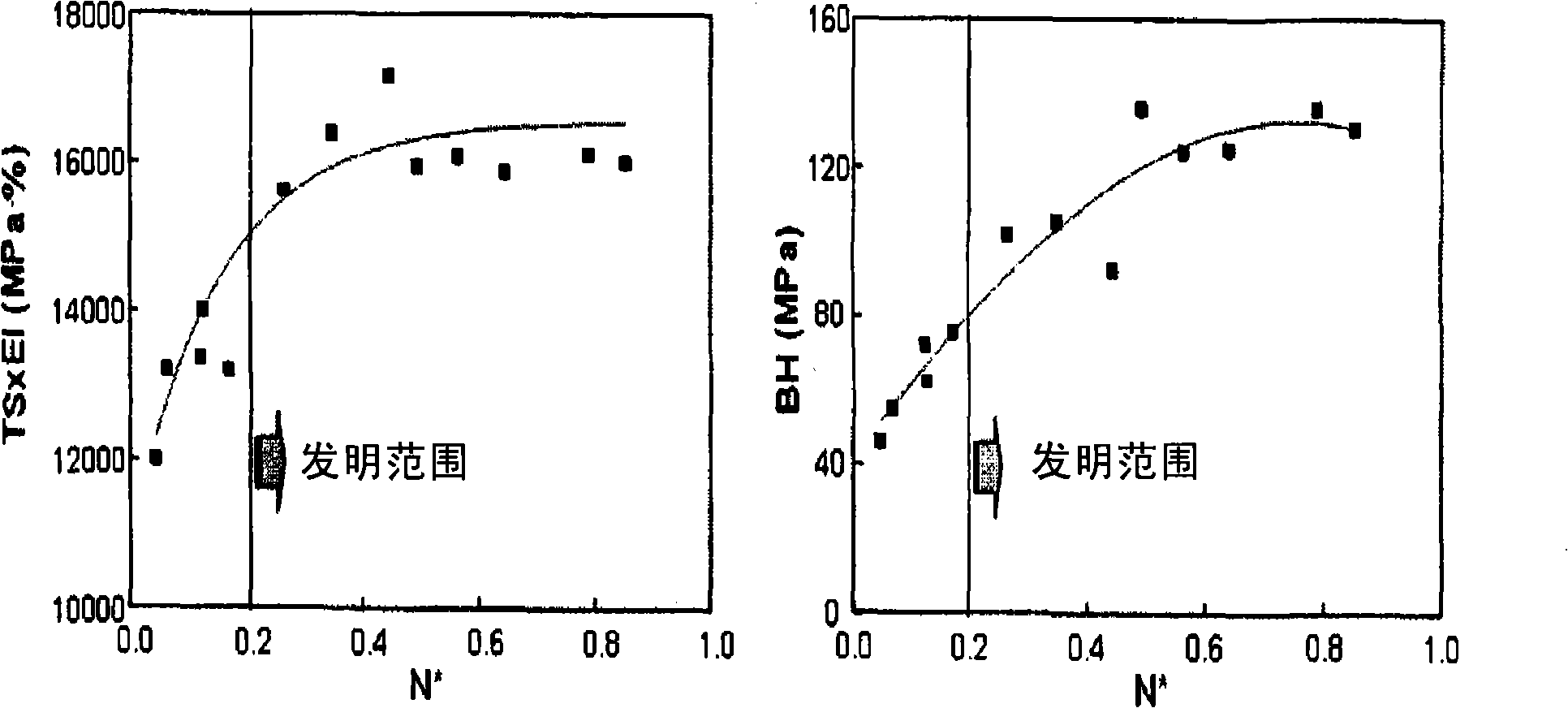

[0037] In addition, when formability needs to be further improved in addition to the above-mentioned coating characteristics, according to one embodiment of the present invention, it is preferable to control the content of nitrogen (N) to satisfy one or both of the following inequalities:

[0038] (Si / 28+Al / 27) / (N / 14)≥10(1)

[0039] N * =(N / 14) / (Al / 27+Ti / 48+Nb / 93+V / 51+B / 11)≥0.2(2)

[0040] Furthermore, in one embodiment of the present invention, the bake hardening characteristics are also improved due to the fixation of dissolved nitrogen after the steel sheet is coated.

[0041] The composition of the steel material according to the present invention will be described below.

[0042] Steel Composition

[0043] Carbon (C): 0.01-0.2%

[0044] Carbon (C) is a very important component for increasing the strength of the steel sheet and securing a composite structure consisting of ferrite and martensite. When the carbon content is less than 0.01%, it is impossible to obtain th...

Embodiment 1

[0106] Thick steel plates having the steel composition shown in Table 1 below were subjected to vacuum melting, heated in a heating furnace at a reheating temperature of 1150° C. to 1250° C. for 1 hour, and then hot rolled and bent. Finish hot rolling at 850°C-950°C. The bending temperature was set at 650°C. Then, the hot-rolled steel sheet is pickled and cold-rolled at a cold-rolling reduction ratio of 50-70%. Under the conditions shown in Table 2, the cold-rolled steel sheets were subjected to continuous annealing, primary cooling and secondary cooling. For tensile strength testing, JIS 5 test strips are taken from continuously annealed cold-rolled steel sheets to check their material quality.

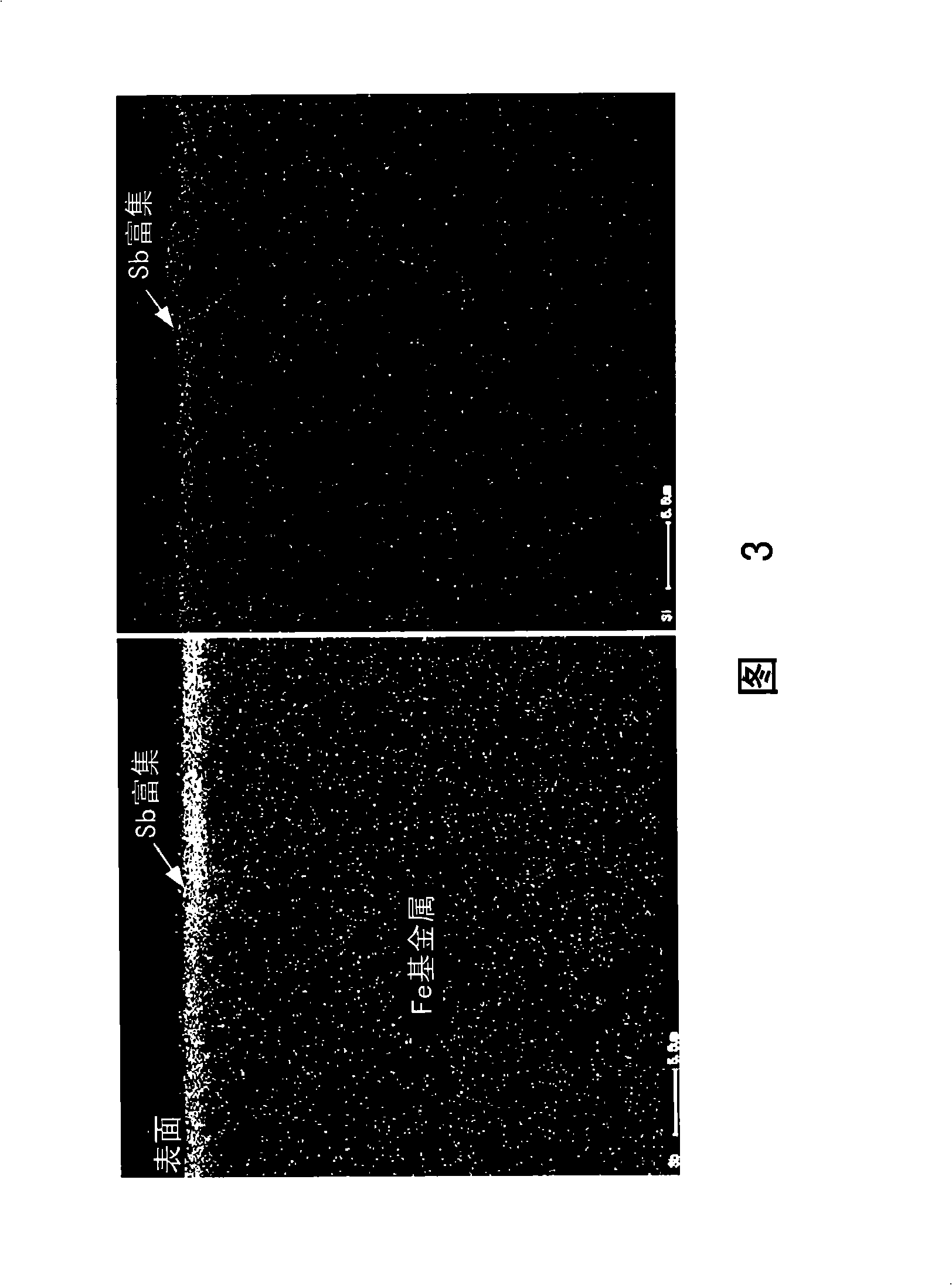

[0107] In addition, in order to observe the coating characteristics, the continuously annealed steel sheet manufactured as described above was heated to 460°C, hot-dip galvanized for 5 seconds, alloyed at 500°C for 10 seconds, then cooled to room temperature, and then observed with...

Embodiment 2

[0121] Thick steel plates having the steel composition shown in Table 4 below were subjected to vacuum melting, heated in a heating furnace at a reheating temperature of 1150° C. to 1250° C. for 1 hour, and then hot rolled and bent. Hot rolling is terminated at 850°C-950°C. The bending temperature was set at 650°C. Then, the hot-rolled steel sheet is pickled and cold-rolled at a cold-rolling reduction ratio of 50-70%. The cold-rolled steel sheets were subjected to continuous annealing, primary cooling and secondary cooling under the conditions shown in Table 5.

[0122]For the tensile strength test, JIS 5 test bars were taken from the annealed cold-rolled steel sheets and examined for their material quality. In addition, in order to simulate the quality of the material after being coated on an automobile part, a 2% strain (strain) was added to the JIS 5 test strip prepared as described above, and then the test strip was boiled in oil at 170° C. for 20 minutes, Tensile stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com