Ti microalloyed ultra-fine grained cold rolling dual-phase steel of 1,000MPa level and preparation method thereof

A 1.1000mpa, micro-alloying technology, used in manufacturing tools, temperature control, heat treatment equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

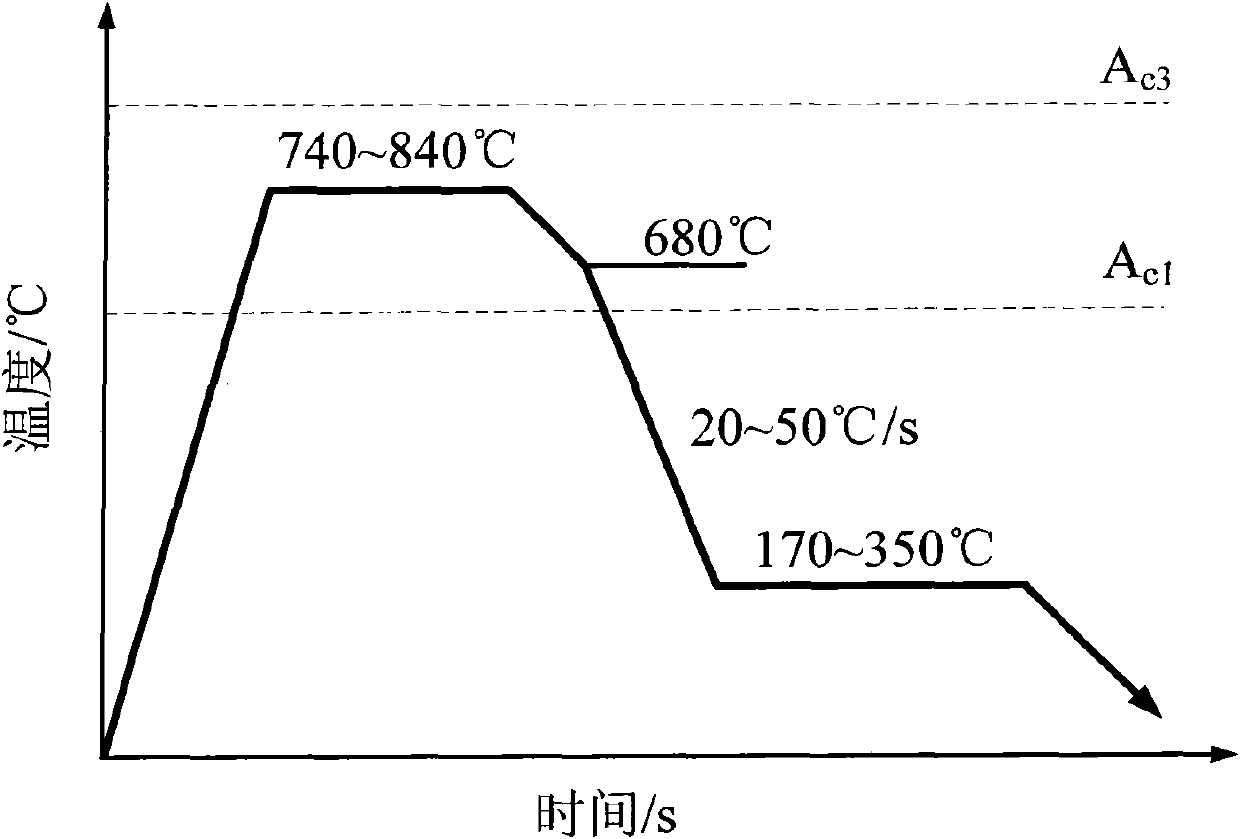

[0027] figure 1 It is a schematic diagram of the continuous annealing process system of the 1000MPa Ti microalloyed ultra-fine grain cold-rolled dual-phase steel of the present invention. As shown in the figure, in the continuous annealing process, the annealing temperature is 740-840°C, and the rapid cooling start temperature is 680°C , the rapid cooling rate is 20-50°C / s, and the overaging temperature is 170-350°C.

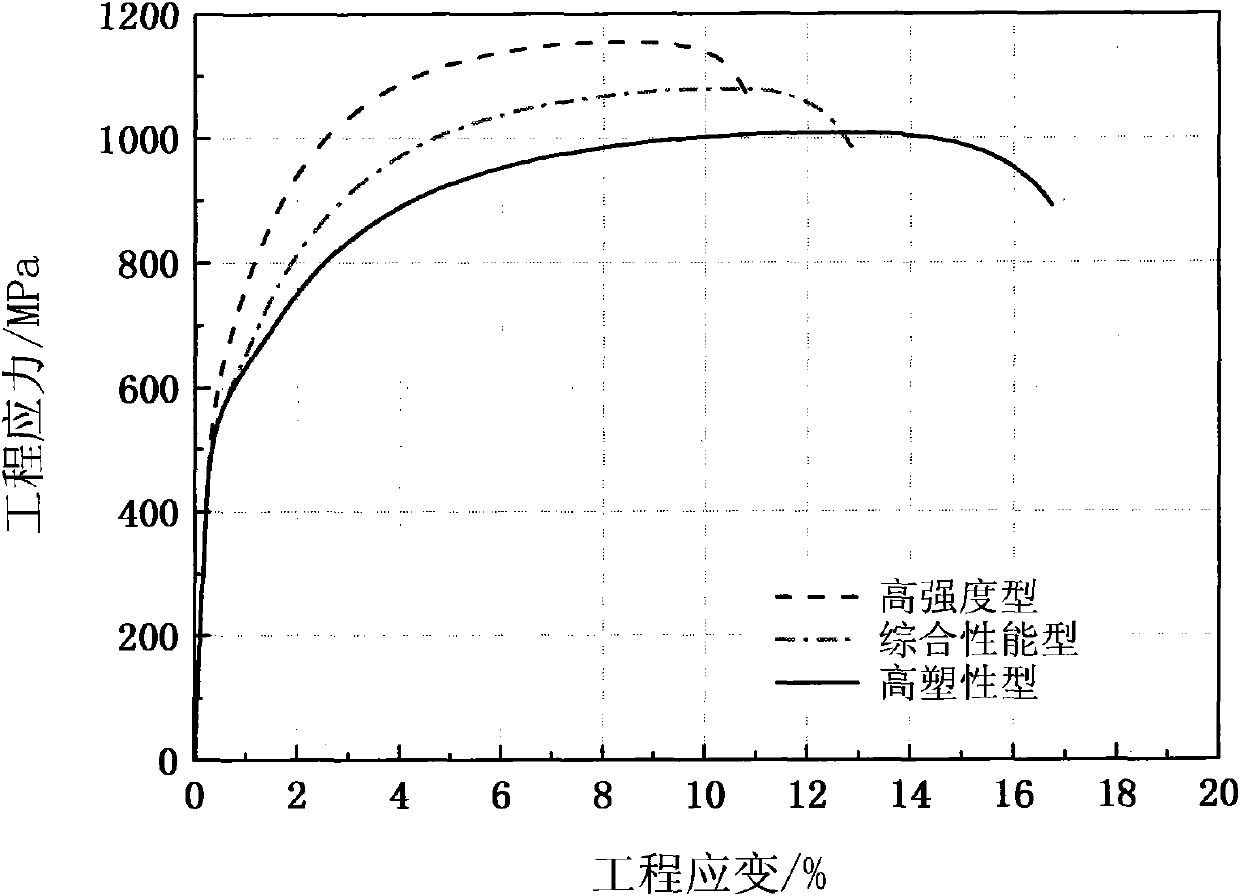

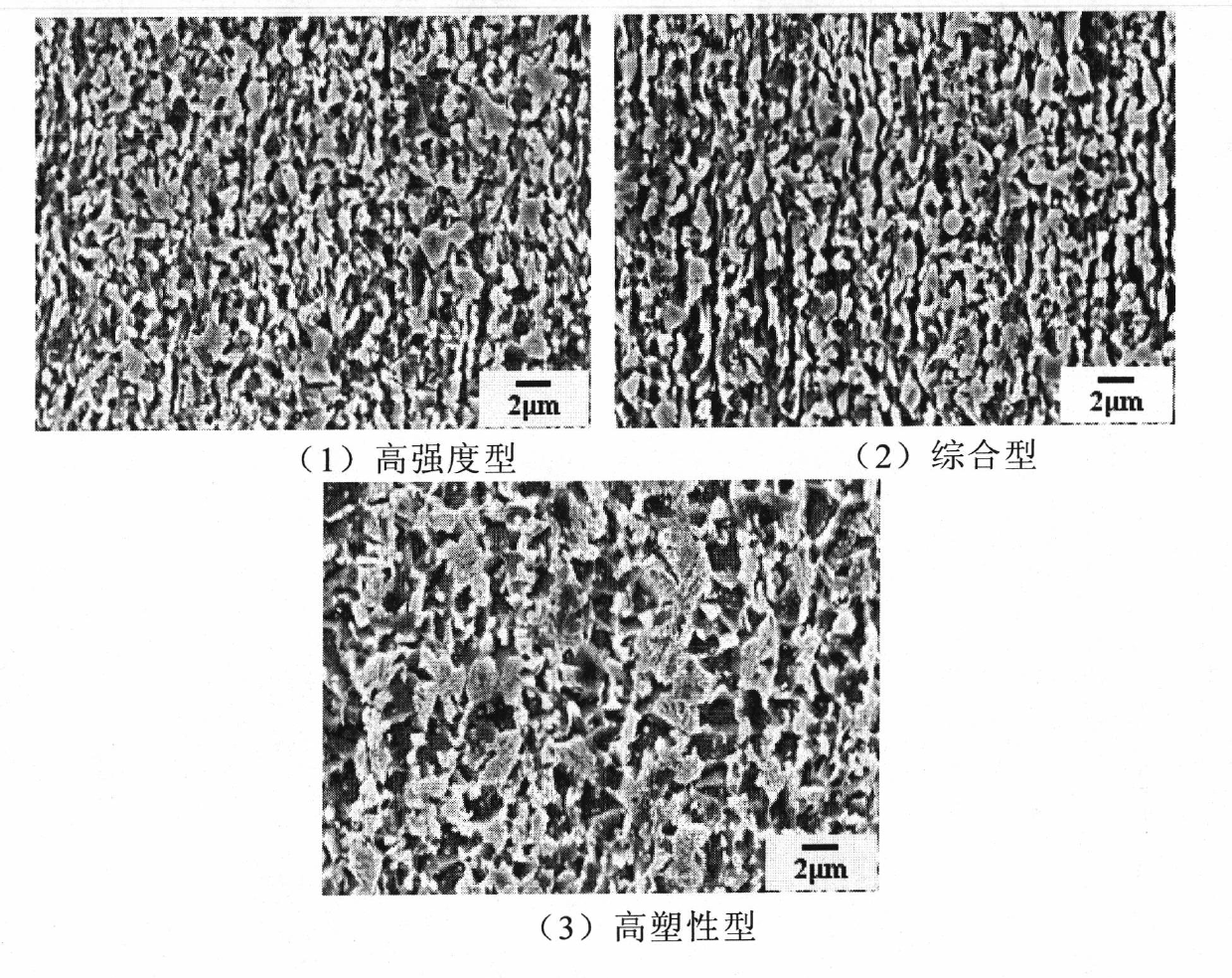

[0028] figure 2 It is a schematic diagram of a typical engineering stress-strain curve of continuous annealing in the embodiment, which is a typical engineering stress-engineering strain curve of ultra-high-strength cold-rolled dual-phase steel, including high-strength type, high plasticity type and comprehensive performance type typical curves. image 3 It is a schematic diagram of a typical SEM structure of continuous annealing in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com