Plasticity-enhanced cold-rolled hot-dip galvanized dual-phase steel and production method thereof

A production method and dual-phase steel technology, applied in the field of steel materials, to reduce costs, improve galvanized surface quality, and reduce alloy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In order to solve the technical problem in the prior art that steel strength requirements and alloy costs cannot be satisfied at the same time, the present application provides a cold-rolled hot-dip galvanized dual-phase steel with enhanced plasticity.

[0035] The chemical composition of the dual-phase steel is by weight percentage:

[0036] C: 0.12%-0.18%; Si: 0.3%-0.6%; Mn: 1.3%-2.3%; P: ≤0.01%; S: ≤0.01%; Al: 0.4%-0.9%, the rest is Fe and unavoidable of impurities.

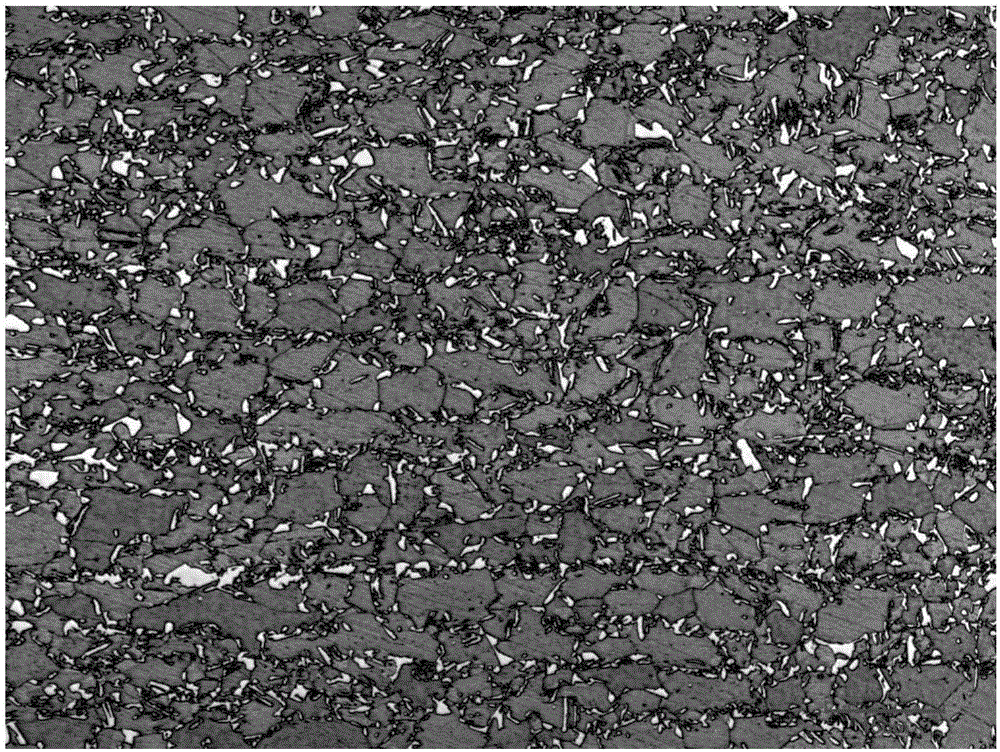

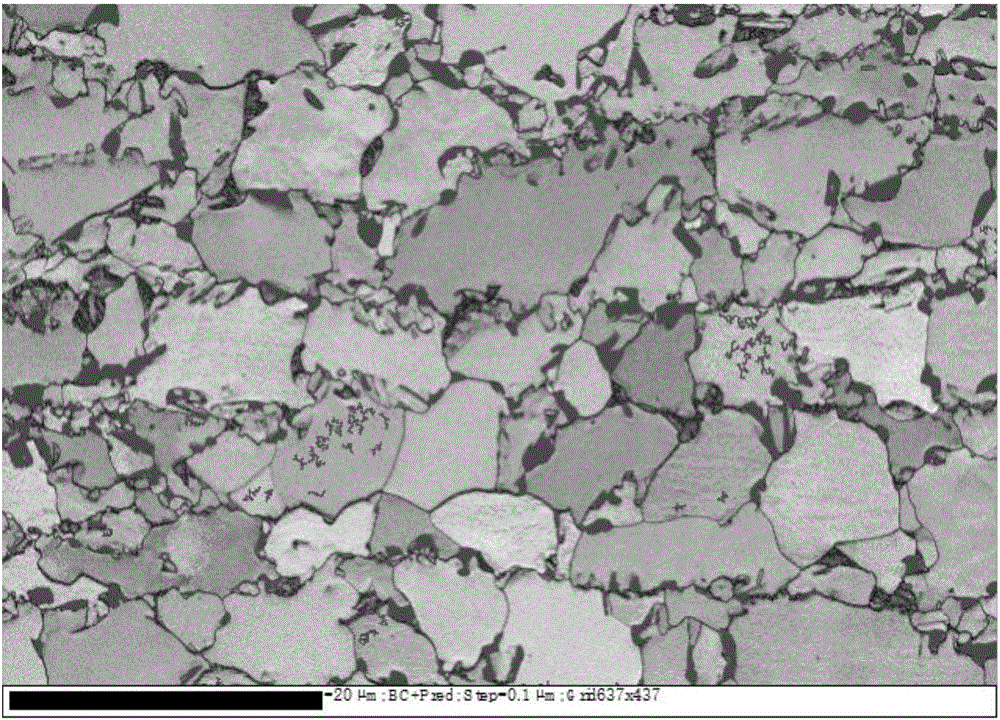

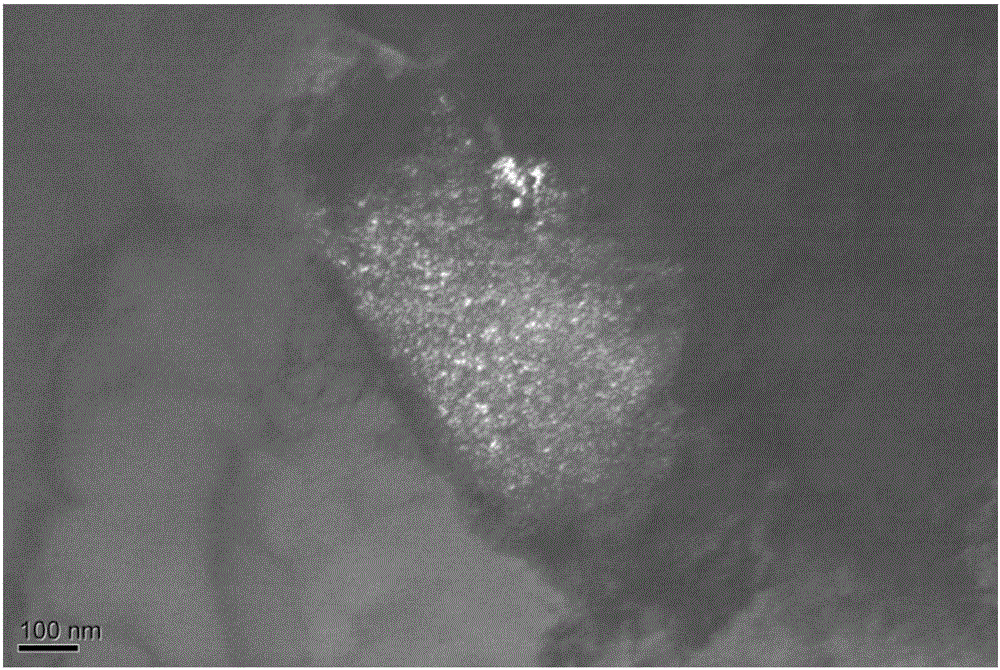

[0037] The metallographic structure diagram of the plastically enhanced cold-rolled hot-dip galvanized dual-phase steel, the metallographic EBSD analysis diagram of the plastically enhanced cold-rolled hot-dip galvanized dual-phase steel, and the plastically enhanced cold-rolled hot-dip galvanized steel TEM analysis diagram of the metallographic phase of dual-phase steel, such as Figure 1 to Figure 3 shown.

[0038] The functions and limits of the above-mentioned main alloying elements are as follow...

Embodiment 2

[0055] Based on the same inventive concept, the present application also provides a method for producing a plastically enhanced cold-rolled hot-dip galvanized dual-phase steel, which is used to produce the plastically enhanced cold-rolled hot-dip galvanized dual-phase steel in Example 1. Such as Figure 4 As shown, the production method of the plastically enhanced cold-rolled hot-dip galvanized dual-phase steel, see Figure 4 , the production method comprises the following steps:

[0056] In step 110, the molten steel is smelted and cast into continuous casting slabs.

[0057] Specifically, the molten steel is smelted and cast into a continuous casting slab, specifically, the molten steel is smelted in a converter, and the steel is cast in a continuous casting manner. The molten steel is the above-mentioned molten steel of the plastically enhanced cold-rolled hot-dip galvanized dual-phase steel.

[0058] Step 120, hot rolling the continuous cast slab to obtain a hot rolled ...

Embodiment 1

[0071] Embodiment 1 to embodiment 4 are cold-rolled hot-dip galvanized dual-phase steels with enhanced plasticity, while the DP590 object and the DP780 object are common dual-phase steels, and the strength level of embodiment 1 and embodiment 2 is 590MPa and traditional DP590 Real object comparison, obviously, the strength grade that embodiment 1 and embodiment 2 provide is that the plastically reinforced cold-rolled hot-dip galvanized dual-phase steel of 590MPa and traditional DP590 object A80 elongation increase 20-40%; Embodiment 3 and embodiment 4 The strength level is 780MPa compared with the traditional DP780 object, obviously, the strength level provided by embodiment 1 and embodiment 2 is 780MPa plastic enhanced cold-rolled hot-dip galvanized dual-phase steel and the traditional DP780 object A80 elongation increased by 20- 40%.

[0072] The plastically enhanced cold-rolled hot-dip galvanized dual-phase steel produces a certain TRIP effect when deformed, thereby produci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com