Production method for Si-contained cold-rolling hot galvanizing dual-phase steel with tensile strength reaching 800MPa level

A technology of tensile strength and production method, which is applied in the production field of cold-rolled hot-dip galvanized dual-phase steel, can solve the problems of low yield ratio, good formability, increased cost, high strength of cold-rolled dual-phase steel, etc., to achieve The equipment is simple, the cost is economical, and the product application performance is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

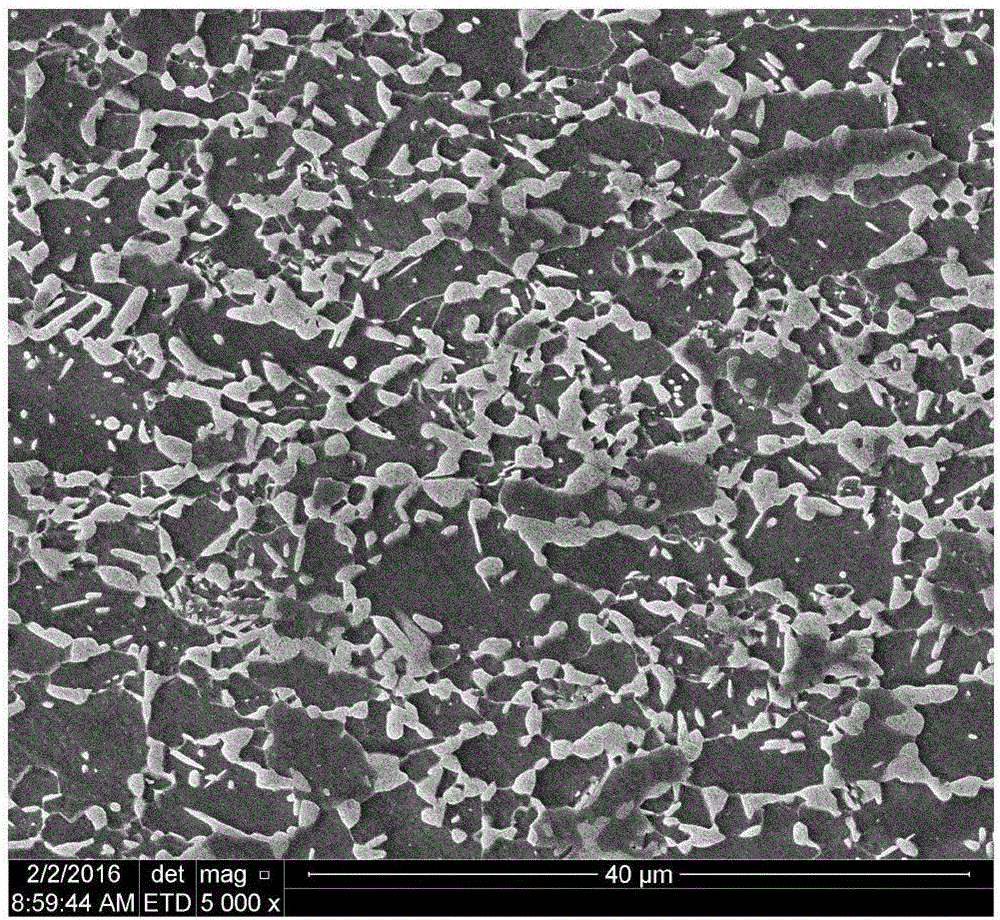

[0038] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

[0039]In a preferred embodiment, an 800MPa grade economical hot-dip galvanized dual-phase steel sheet containing Si has the following chemical composition mass percentages: C: 0.08-0.12%; Si: 0.10-0.18%; Mn: 1.5-2.5% %; Cr: 0.2~0.4%; Mo: 0.12~0.20%; Als: 0.03-0.06%, P≤0.015%, S≤0.04%, N:≤0.005%, and the balance is Fe and unavoidable impurities.

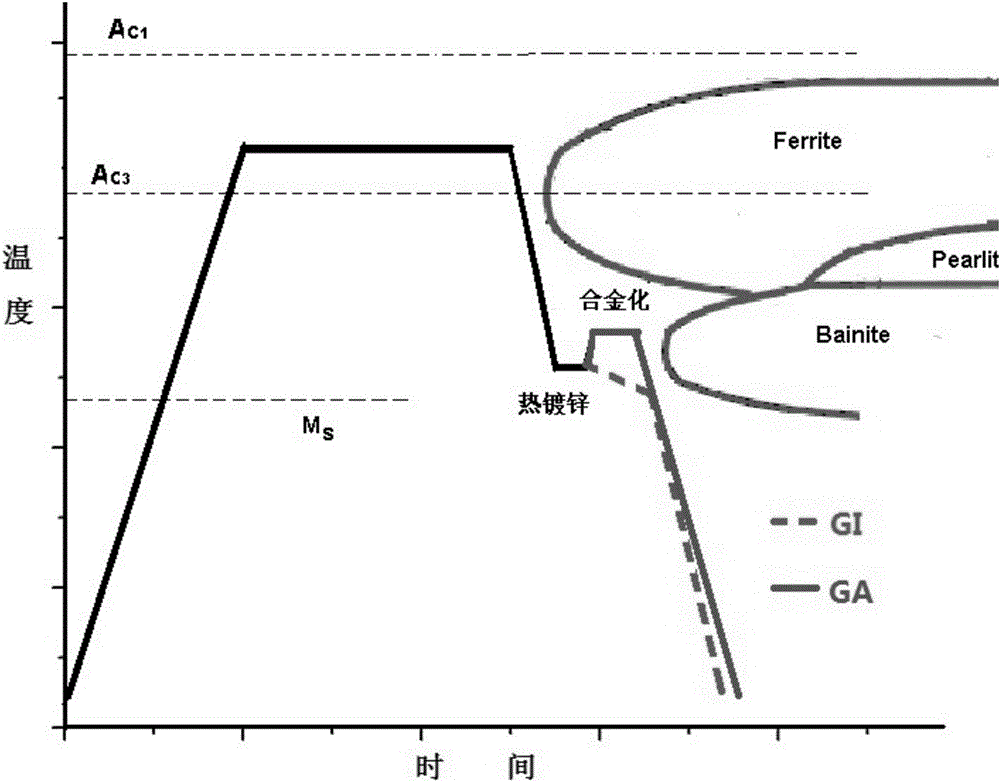

[0040] The preparation method of the present invention comprises the following steps in turn:

[0041] (1) Smelting and solidification: suitable for smelting in converters, electric furnaces and induction furnaces; continuous casting is used to produce slabs, and dynamic light reduction and electromagnetic stirring systems can be used to ensure the quality of slabs;

[0042] (2) Continuous hot rolling of cast slab or ingot: heat the cast slab a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com