High tensile strength hot rolled ferrite bainite dual phase steel and preparation method thereof

A technology with high tensile strength and tensile strength, applied in temperature control and other directions, can solve the problems of adverse effects of steel hole expansion performance, difficult steelmaking process, and high process requirements, and achieve excellent hole expansion performance and formability, and material cost. The effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

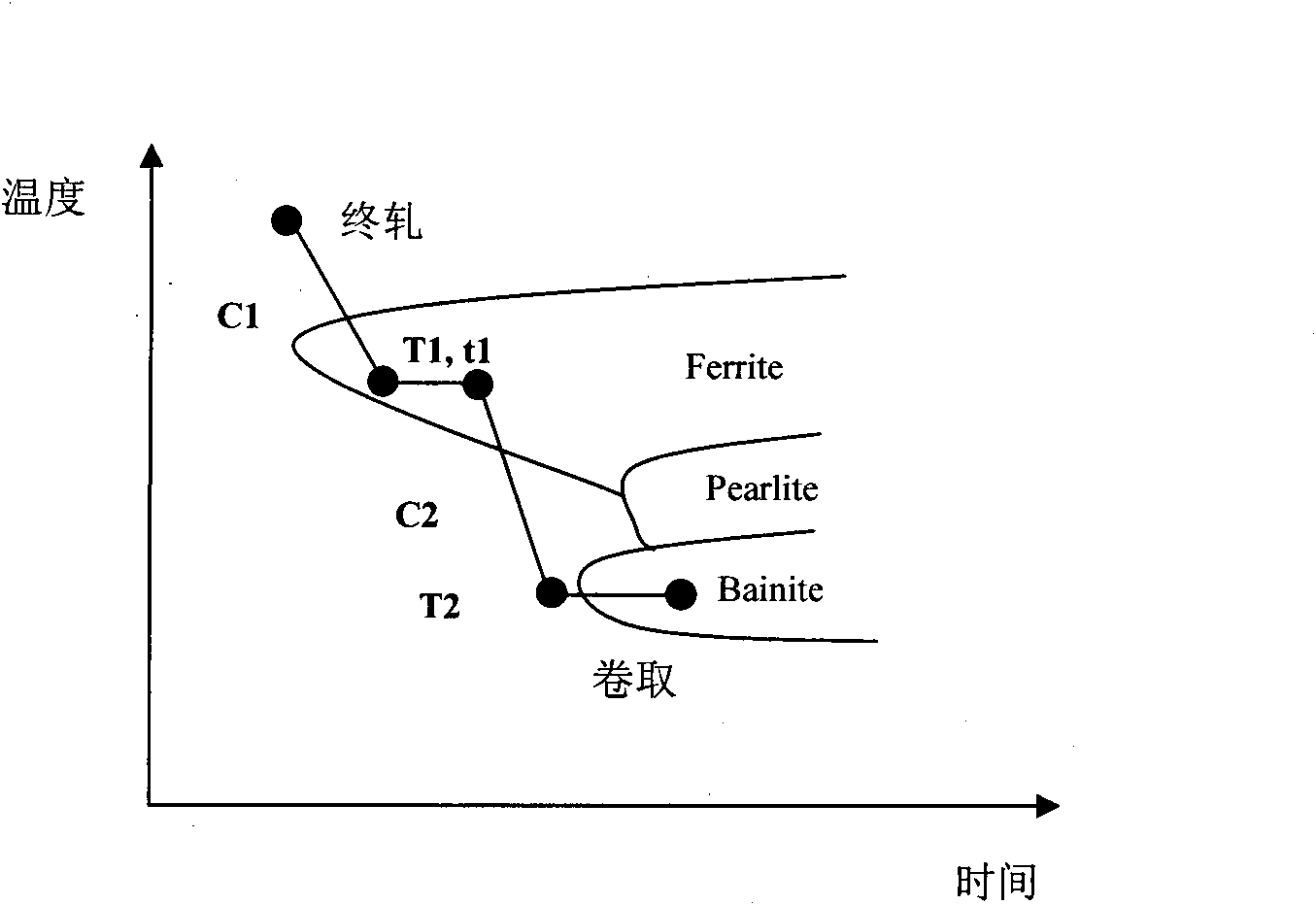

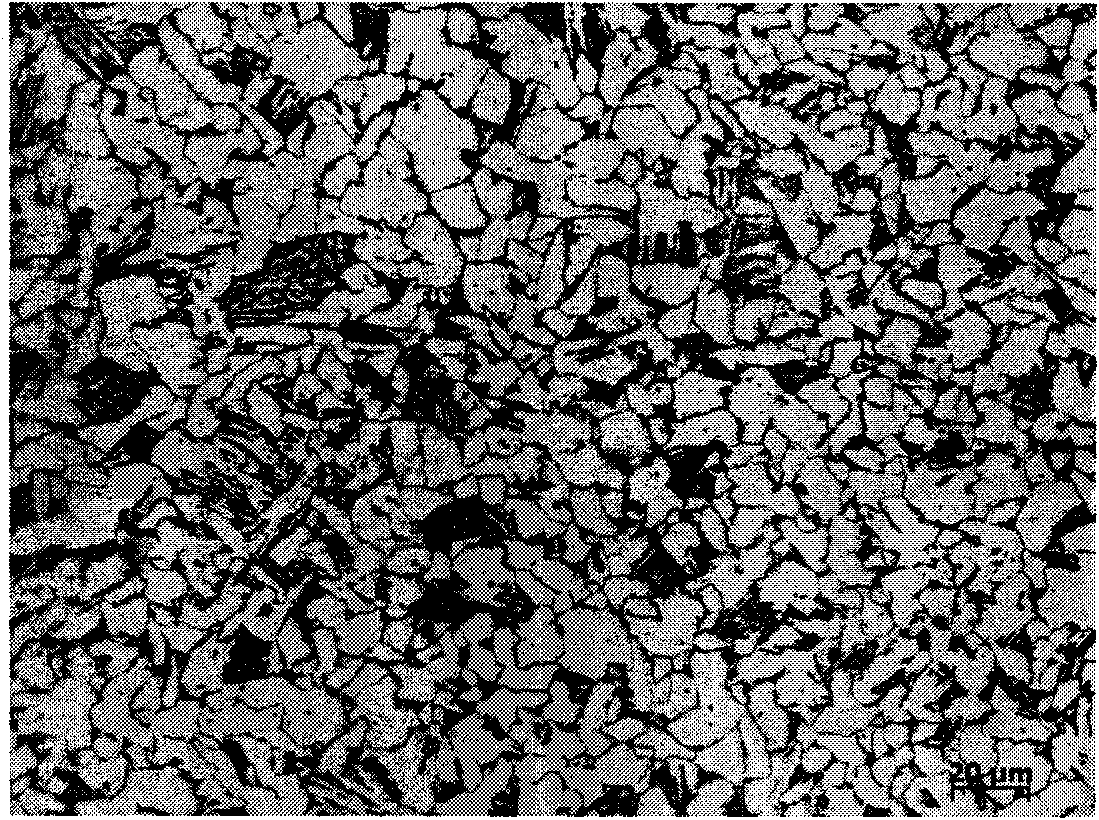

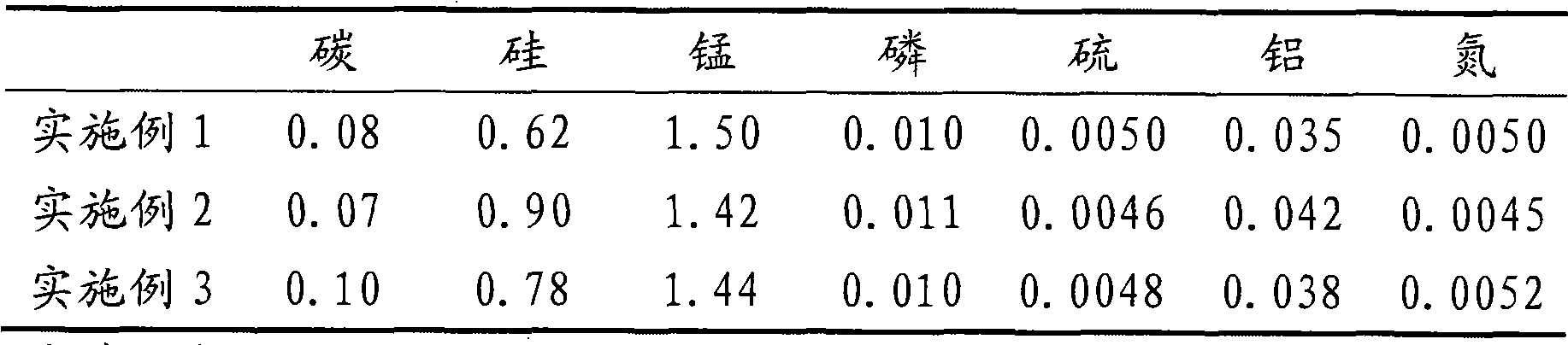

[0034] Example 1: The steel ingot was smelted in a vacuum induction furnace, and its chemical composition is shown in Table 1. Rolling was performed on a laboratory 550mm reversing mill. The rolling process is as follows: heating the steel ingot to about 1200°C, keeping it warm for 1 hour, the rough rolling start temperature is about 1150°C, the finish rolling start temperature is 954°C, and the finish rolling finish temperature is 847°C. After 2 passes of rough rolling and 5 passes of finishing rolling, the thickness of the material is rolled from 90mm to 10mm, and the reduction ratio is distributed at 30%-30%-30%-25%-25%-25%-20%. Such as Figure 1 It shows that the cooling process is C1: about 30°C / s; air cooling start temperature T1: 718°C; air cooling time t1: 5s, C2: 20°C / s; coiling temperature T2: 487°C (simulated coiling with heat treatment furnace) , the mechanical properties of the obtained steel are shown in Table 2, and its structure is as follows figure 2 shown...

Embodiment 2

[0035]Example 2: Steel ingots were smelted in a vacuum induction furnace, and the chemical composition is shown in Table 1. Rolling was performed on a laboratory 550mm reversing mill. The rolling process is as follows: heating the steel ingot to about 1220°C, holding it for 1 hour, the start temperature of rough rolling is about 1136°C, the start temperature of finish rolling is 981°C, and the finishing temperature is controlled at 859°C. After 2 passes of rough rolling and 5 passes of finishing rolling, the thickness of the material is rolled from 90mm to 10mm, and the reduction ratio is distributed at 30%-30%-30%-25%-25%-25%-20%. The cooling process is C1: about 30°C / s, air cooling start temperature T1: 693°C, air cooling time t1: 3s, C2: 33°C / s; coiling temperature T2: 457°C (simulated coiling with heat treatment furnace), the obtained steel The mechanical properties are shown in Table 2, and the structure is similar to Example 1.

Embodiment 3

[0036] Example 3: Steel ingots were smelted in a vacuum induction furnace, and the chemical composition is shown in Table 1. Rolling was performed on a laboratory 550mm reversing mill. The rolling process is as follows: heating the steel ingot to about 1230°C, holding it for 1 hour, the rough rolling start temperature is about 1143°C, the finish rolling start temperature is 961°C, and the finish rolling finish temperature is controlled at 835°C. After 2 passes of rough rolling and 5 passes of finishing rolling, the thickness of the material is rolled from 90mm to 10mm, and the reduction ratio is distributed at 30%-30%-30%-25%-25%-25%-20%. Such as Figure 1 It shows that the cooling process is C1: about 30°C / s, air cooling start temperature T1: 706°C, air cooling time t1: 5s, C2: 40°C / s; coiling temperature T2: 451°C (simulated coiling with heat treatment furnace) , the mechanical properties of the steel obtained are shown in Table 2, and the structure is similar to that of E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com