Ultra-high strength steel plate having excellent formability and hole-expandability, and method for manufacturing same

An ultra-high-strength, manufacturing method technology, applied in the direction of chemical instruments and methods, manufacturing tools, furnace types, etc., can solve the problem of poor yield strength and hole expandability, can not be given by stamping, no attempt to improve yield strength and expandability Porosity and other issues, to achieve excellent elongation, suppress the generation of CO2, and excellent hole expandability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0127] Hereinafter, the present invention will be described in more detail through examples. However, it should be noted that the following examples are only for illustrating the present invention in more detail and do not limit the scope of rights of the present invention. This is because the scope of rights of the present invention is determined by the content described in the claims and the content reasonably derived therefrom.

[0128] (Example)

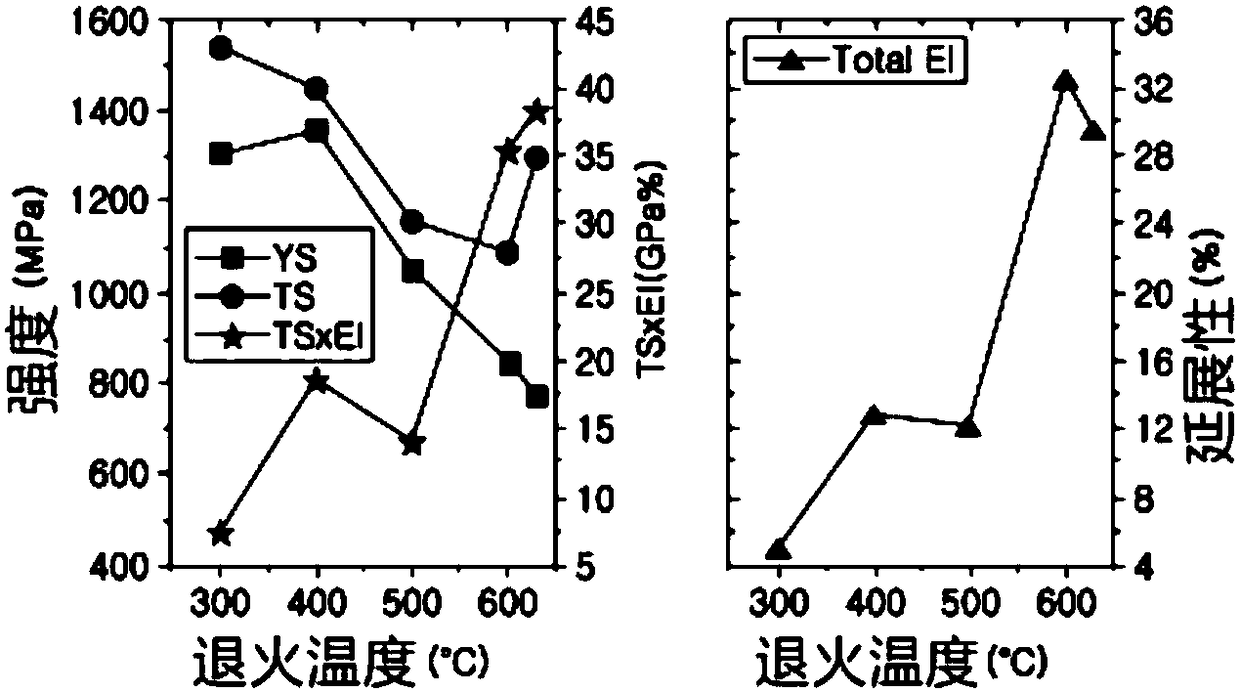

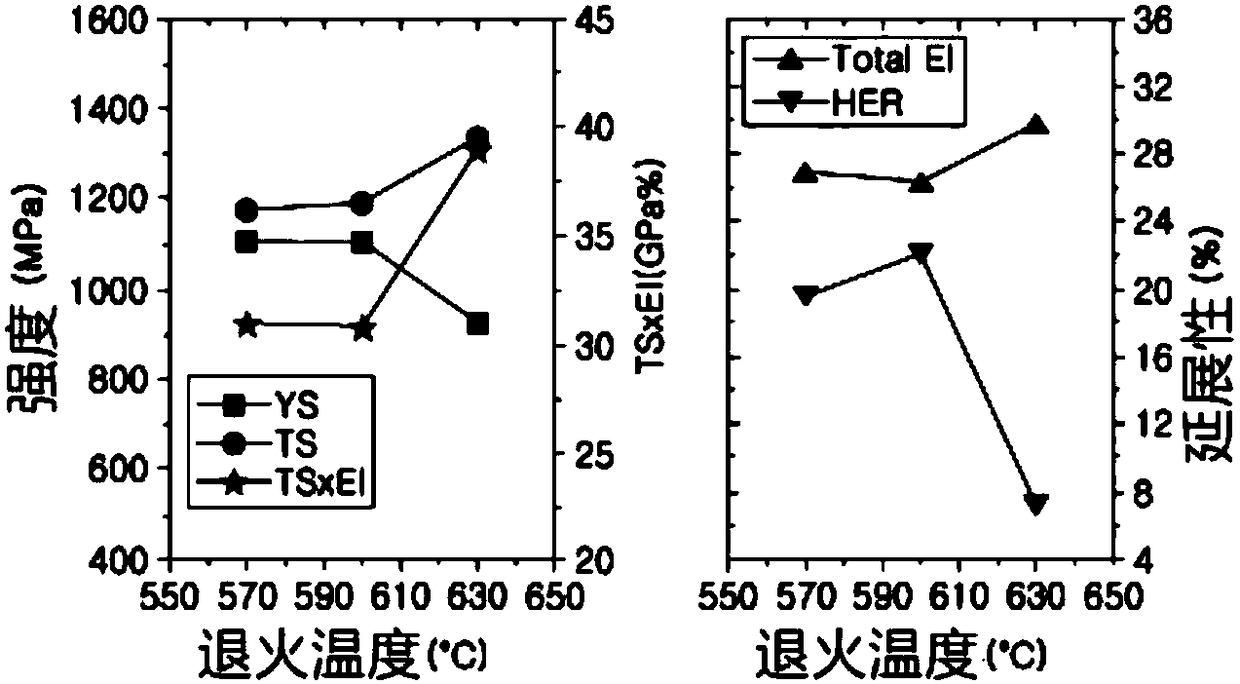

[0129] The steel with the composition of the following Table 1 was vacuum dissolved into a 30kg steel ingot, and then hot rolled at a temperature of 1200°C for 1 hour, and the finish rolling was completed at 900°C. Heating to a furnace at 600° C. and maintaining it for 1 hour, and then performing hot rolling and coiling by furnace cooling. Then, after the test piece was cooled to normal temperature, it was heat-treated at 600° C. for 10 hours, pickled and then cold-rolled at a cold reduction ratio of 50%, to produce a cold-roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com