Novel powder selecting machine capable of uniformly scattering material

A powder classifier and uniform technology, applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc., can solve problems such as easy to run rough, run rough, affect powder dispersion, etc., to achieve increased Large throwing area, increased spreading effect, and improved grading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

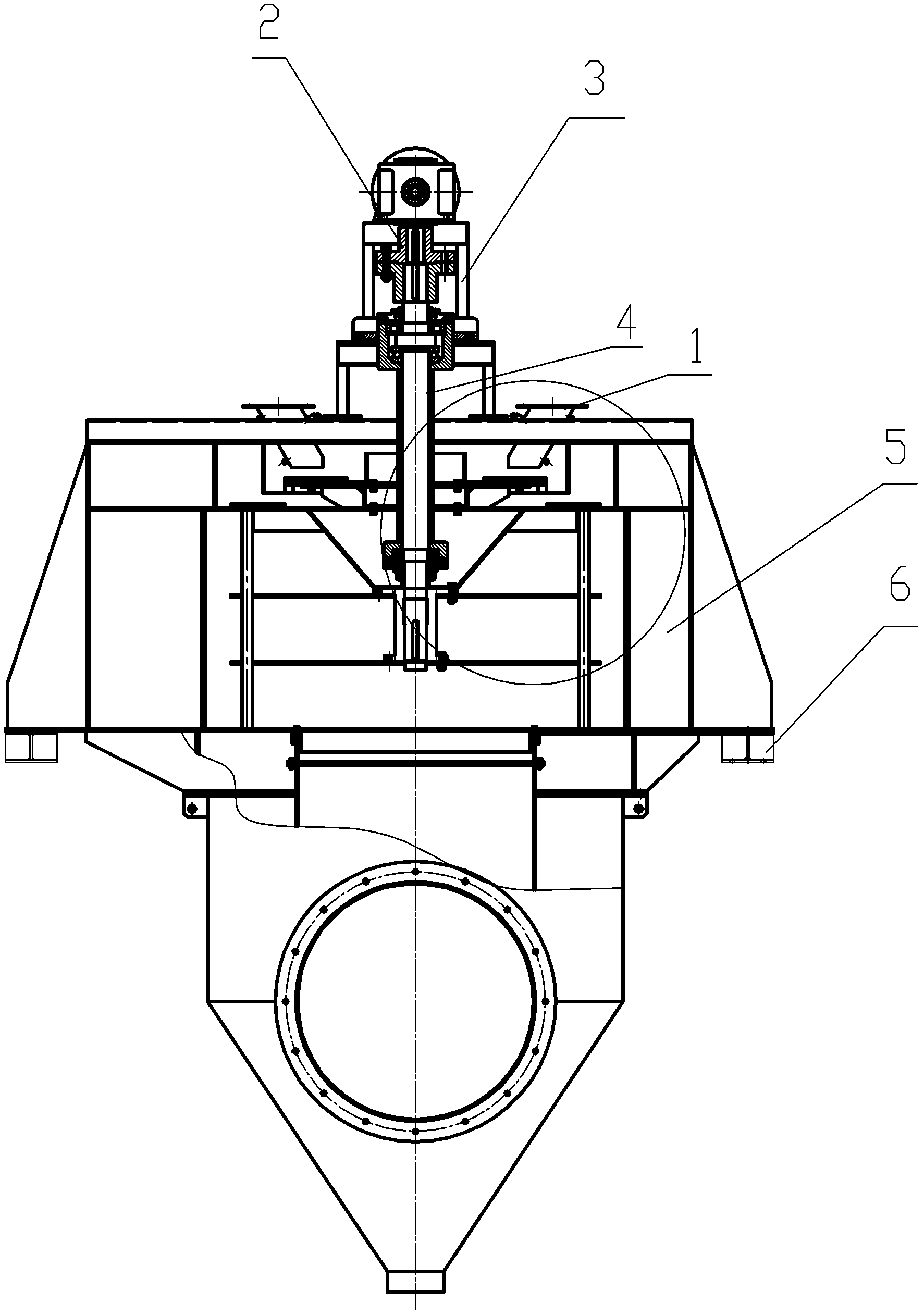

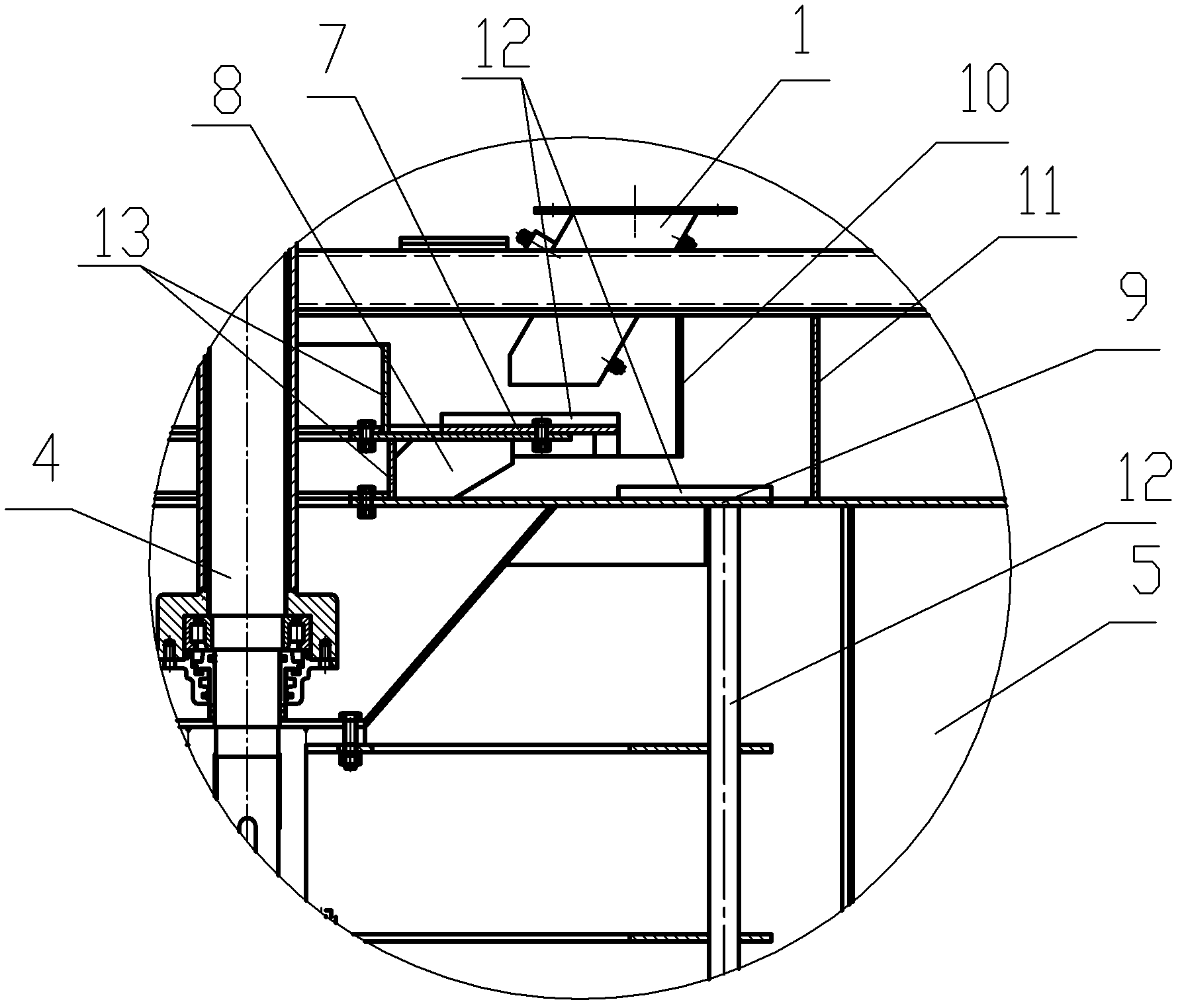

[0017] to combine figure 1 and figure 2 As shown, the novel classifier for evenly spreading materials in this embodiment includes a cylindrical housing 5, a support 6 for supporting the housing, a motor, a reducer, a shaft coupling 2, a frame 3, and a The rotating parts in the body, the motor drives the rotating parts to rotate through the reducer and the coupling. Described revolving part comprises rotating shaft 4, rotor 12, and the top of rotor 12 is fixedly provided with annular material spreading plate, and this material spreading plate is double-layer and comprises top layer material spreading plate 7 and bottom layer material spreading plate 9, top layer material spreading plate The disk 7 is set under the feed port 1 of the powder classifier, and a ring-shaped primary buffer plate 10 is arranged on the outer edge of the top layer of material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com