Coarsness grading process for mineral separation and grinding

A coarse-grained, ore-grinding technology, which is applied in grain processing, etc., can solve the problems of occupying the volume of the ball mill, affecting the metal recovery rate, and affecting the performance of the ball mill table, and achieves the effect of improving the classification effect, simple structure, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

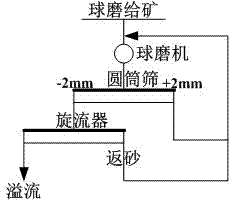

[0015] Such as figure 1 Shown, the coarse-grained classification process in ore dressing and grinding, it comprises the following steps:

[0016] 1) Preparation of the ball mill with a quality separation sieve: install a quality separation sieve (cylindrical sieve) at the ore discharge outlet of the ball mill, and the quality separation sieve is fixed on the end cover of the ore discharge outlet of the ball mill. 2mm; when working, the quality sieve rotates with the ball mill;

[0017] 2) Feed the ore to the ball mill with a classifying screen for grinding, and the minerals flowing out from the grid plate of the ball mill enter the sieve body of the classifying screen from the ore discharge outlet of the ball mill. Under the propulsio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com