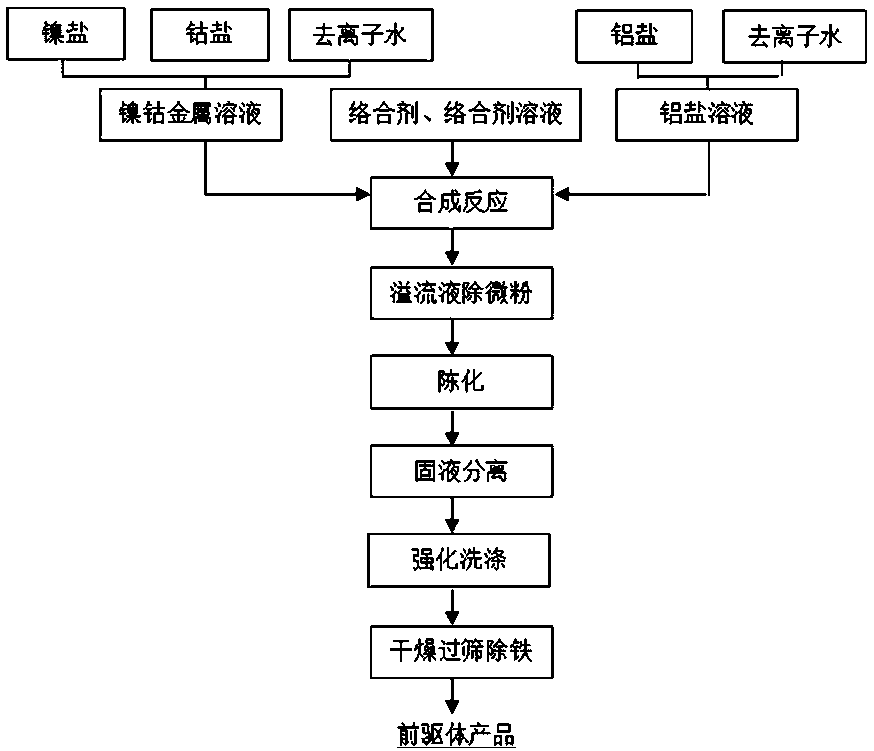

Method for synthesizing wide-particle-size-distribution nickel-cobalt-aluminum positive electrode material precursor through continuous coprecipitation

A cathode material and degree distribution technology, applied in chemical instruments and methods, battery electrodes, nickel compounds, etc., can solve problems such as the deterioration of the lattice order of the precursor, the inability to achieve uniform mixing of aluminum, and the poor electrochemical performance of the product. , to achieve the effect of good dispersion, low cost and less residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

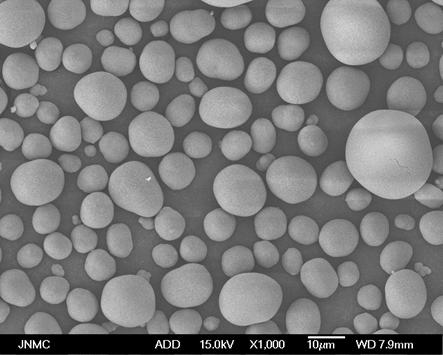

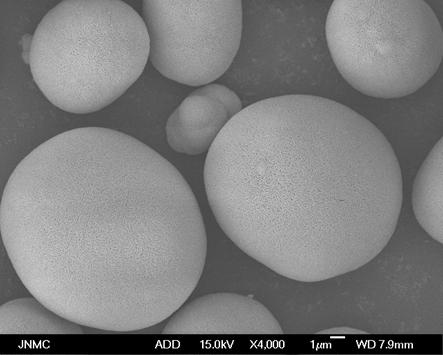

[0030] A wide particle size distribution Ni with a D50 of 12 μm 0.9 co 0.08 al 0.02 (OH) 2.02The preparation method of cathode material precursor comprises the following steps:

[0031] (1) Synthesize spherical nickel cobalt aluminum hydroxide powder in the reactor first: accurately weigh nickel sulfate and cobalt sulfate according to the element molar ratio Ni:Co=90:8, and dissolve them in deionized water to prepare 2mol / L Nickel-cobalt metal mixed salt solution; weigh aluminum sulfate and dissolve it in deionized water, add 100g caustic soda for every liter of solution and stir well, and finally prepare 0.5mol / L Al 3+ Salt solution; according to the element molar ratio Ni:Co:Al=90:8:2, accurately set the flow rate of nickel-cobalt mixed salt solution and aluminum salt solution, and 2.5mol / L complexing agent solution, 5mol / L precipitant solution And flow into the reactor equipped with bottom liquid to carry out the liquid phase synthesis reaction. At the beginning of the...

Embodiment 2

[0036] A wide particle size distribution Ni with a D50 of 11 μm 0.91 co 0.06 Al 0.03 (OH) 2.03 The preparation method of cathode material precursor, the method is carried out according to the following steps:

[0037] (1) Synthesize spherical nickel-cobalt-aluminum hydroxide powder in the reactor first: Accurately weigh nickel sulfate and cobalt sulfate according to the element molar ratio Ni:Co=91:6, and dissolve them in deionized water to prepare 1.5mol / L Nickel-cobalt metal mixed salt solution; Weigh aluminum sulfate and dissolve it in deionized water, add 100g caustic soda for every liter of solution and stir fully, and finally prepare 0.5mol / L Al 3+ Salt solution: accurately set the flow rate of nickel-cobalt mixed salt solution and aluminum salt solution according to the element molar ratio Ni:Co:Al=91:6:3, and the complexing agent solution of 2.5mol / L and the precipitating agent solution of 5mol / L And flow into the reactor equipped with bottom liquid to carry out th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com