Airflow grader

A technology of airflow classification and airflow, which is applied in the direction of separating solids from solids with airflow, solid separation, chemical instruments and methods, etc., can solve the problems of complex structure of the whole machine, high energy consumption, and large energy consumption, and achieve guaranteed Grading quality, improving the effect of grading, and improving the effect of grading fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

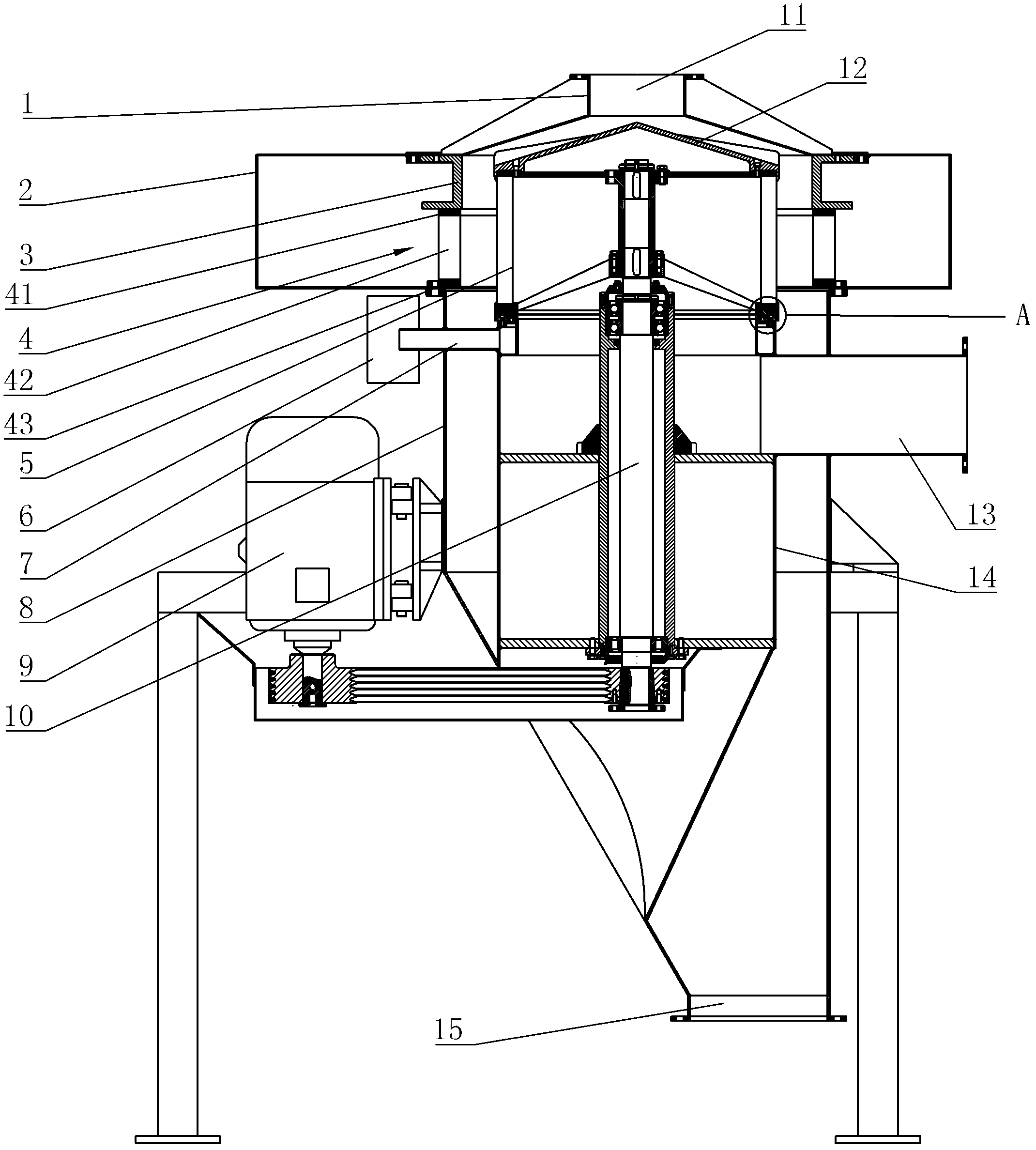

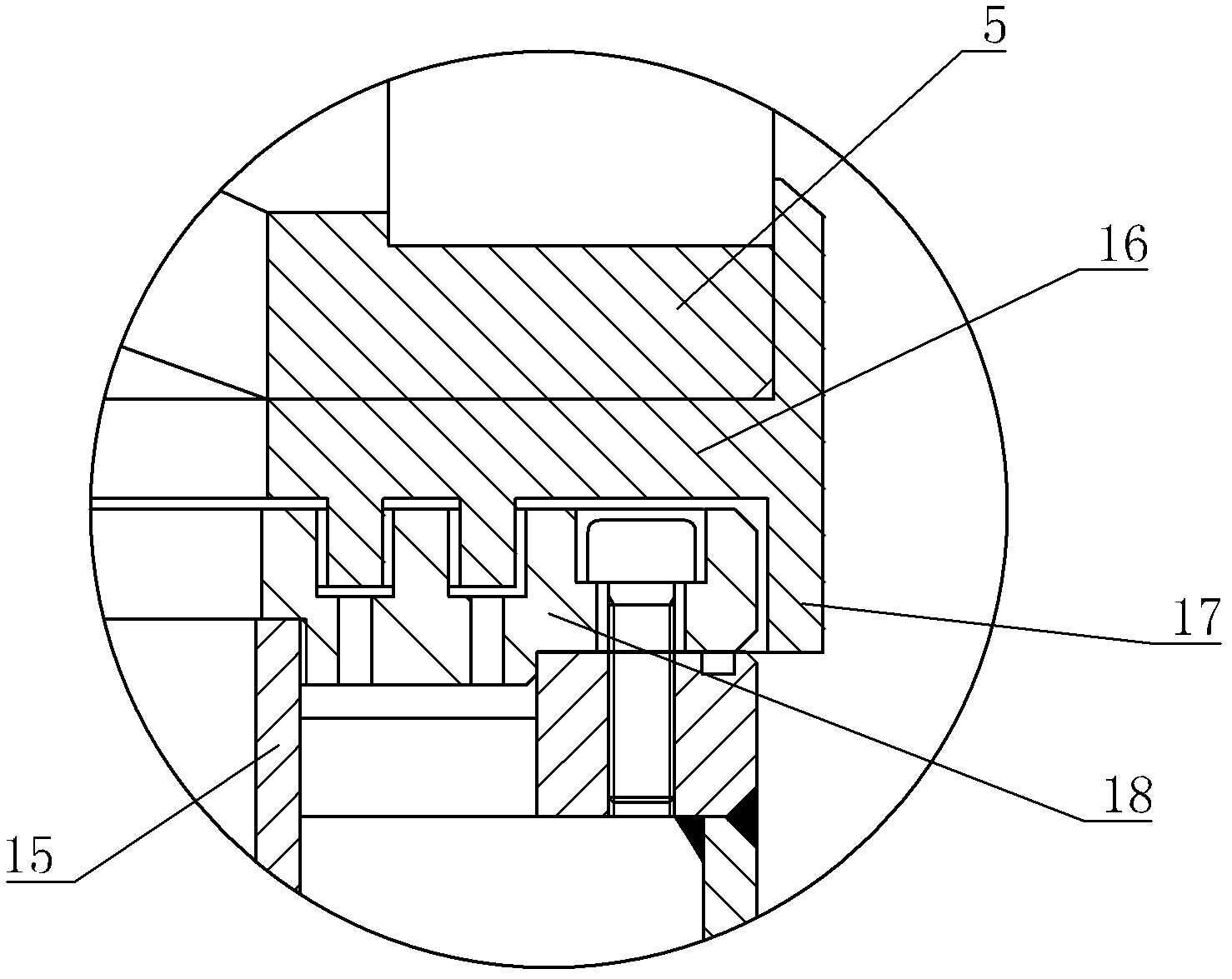

[0022] like figure 1 , figure 2 with image 3 Commonly shown, an air classifier includes a classifying impeller 5 driven by a power device, the classifying impeller 5 is fixedly mounted on a main shaft 10, the power device is usually a motor 9, and the motor 9 is connected to the main shaft 10 in transmission , the rotating speed of the grading impeller 5 can be changed through a frequency converter;

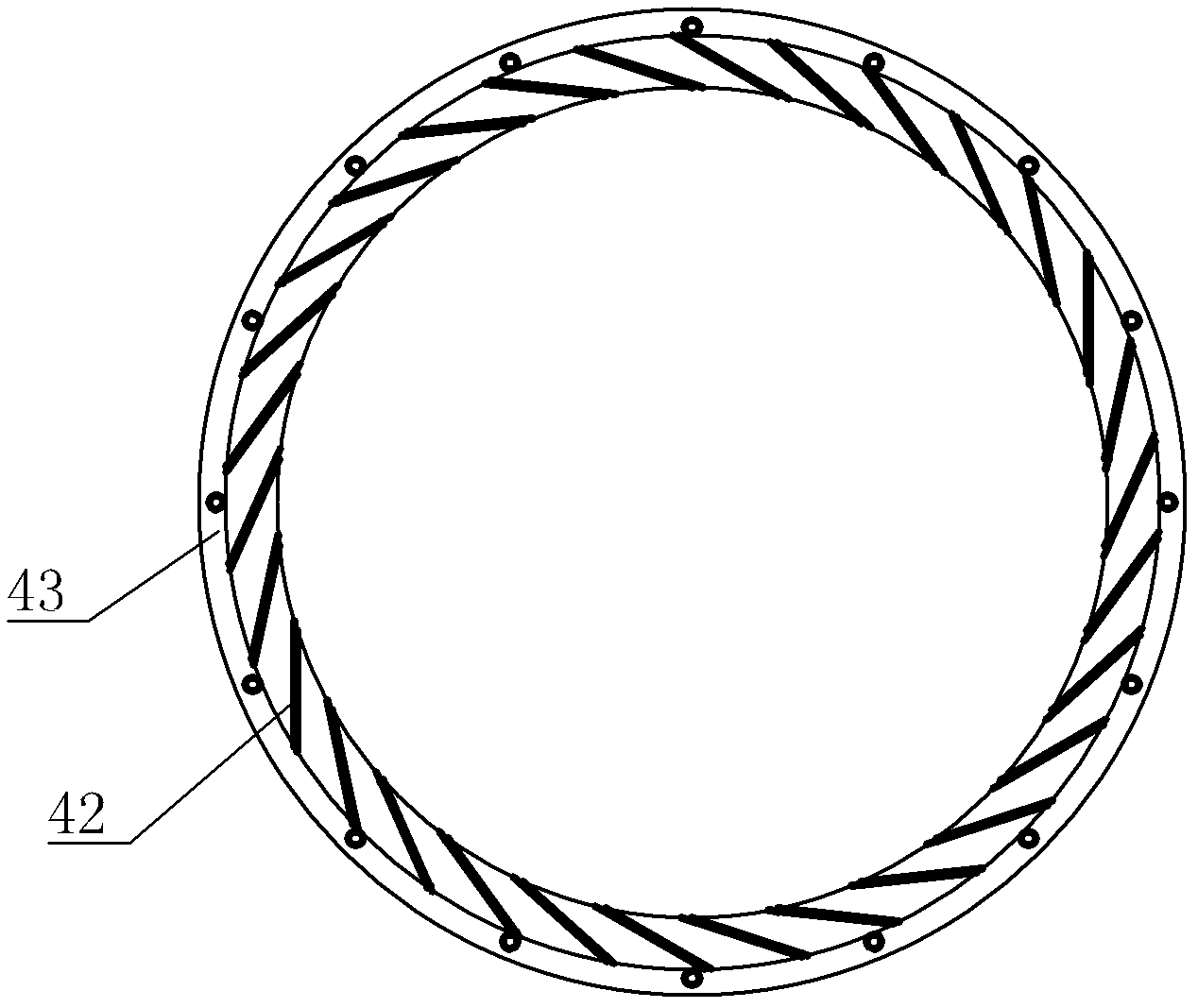

[0023] The outer periphery of the classifying impeller 5 is provided with a cyclone 2 for the passage of the classified airflow, and the cyclone 2 is provided with an air inlet, and a classifying cavity for classifying materials is formed between the cyclone 2 and the classifying impeller 5, and the The cyclone 2 is fixedly installed with a deflector 4 that guides the classified airflow to blow to the grading impeller 5. The deflector 4 includes an annular upper disc 41 and a lower disc 43. There are several guide vanes 42, the guide vanes 42 are distributed in an annular ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com