Fuzzy closed circuit self-turning dynamic hydraulic cyclone classifier

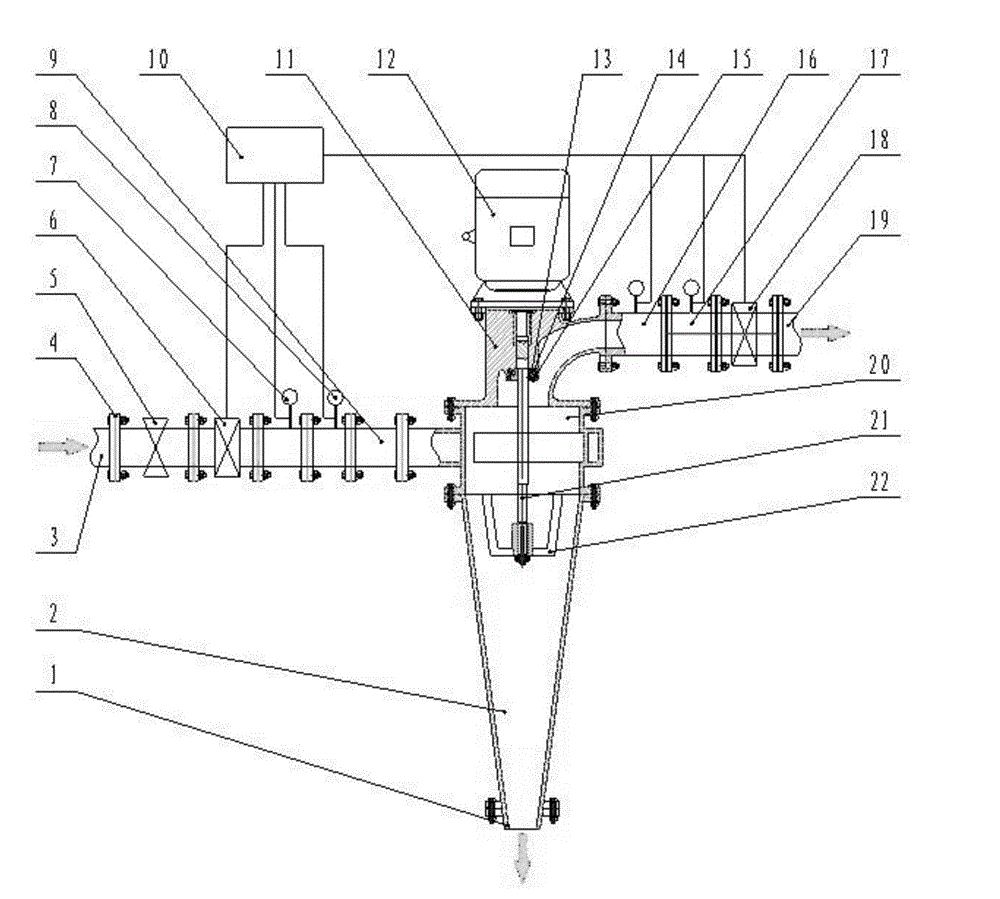

A dynamic hydrocyclone, self-tuning technology, used in solid separation, wet separation, chemical instruments and methods, etc., to achieve the effect of high cyclone intensity, high degree of automation, and obvious particle dispersion and layering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: the present invention is as follows to the concrete production operation process of iron ore:

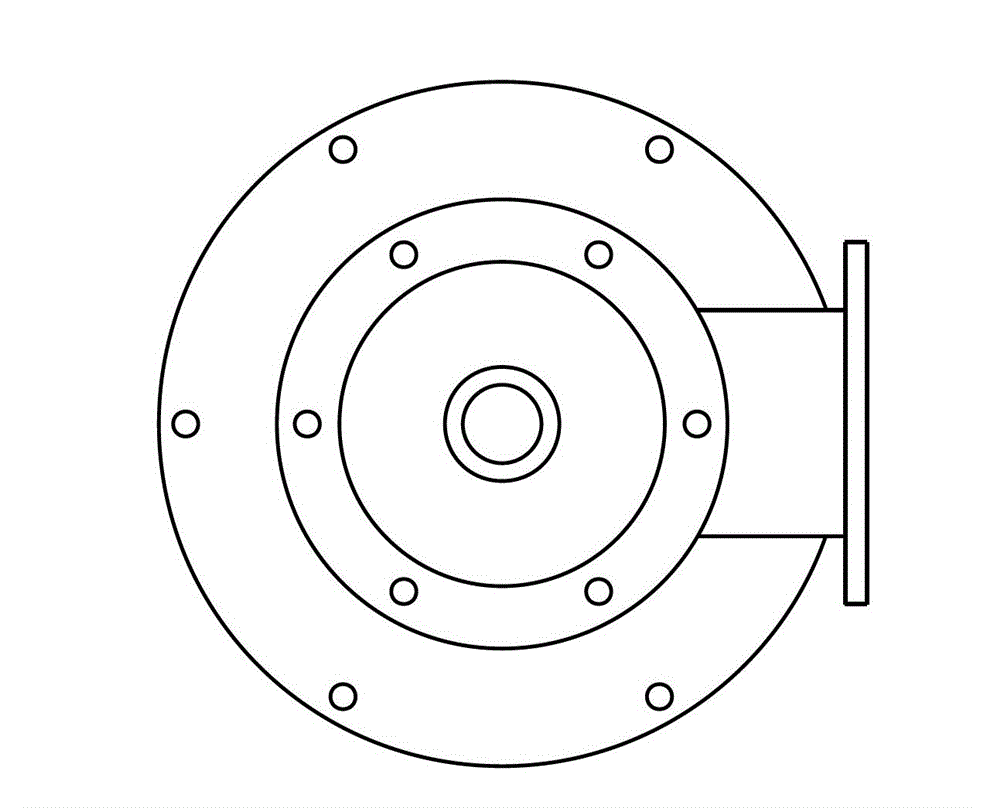

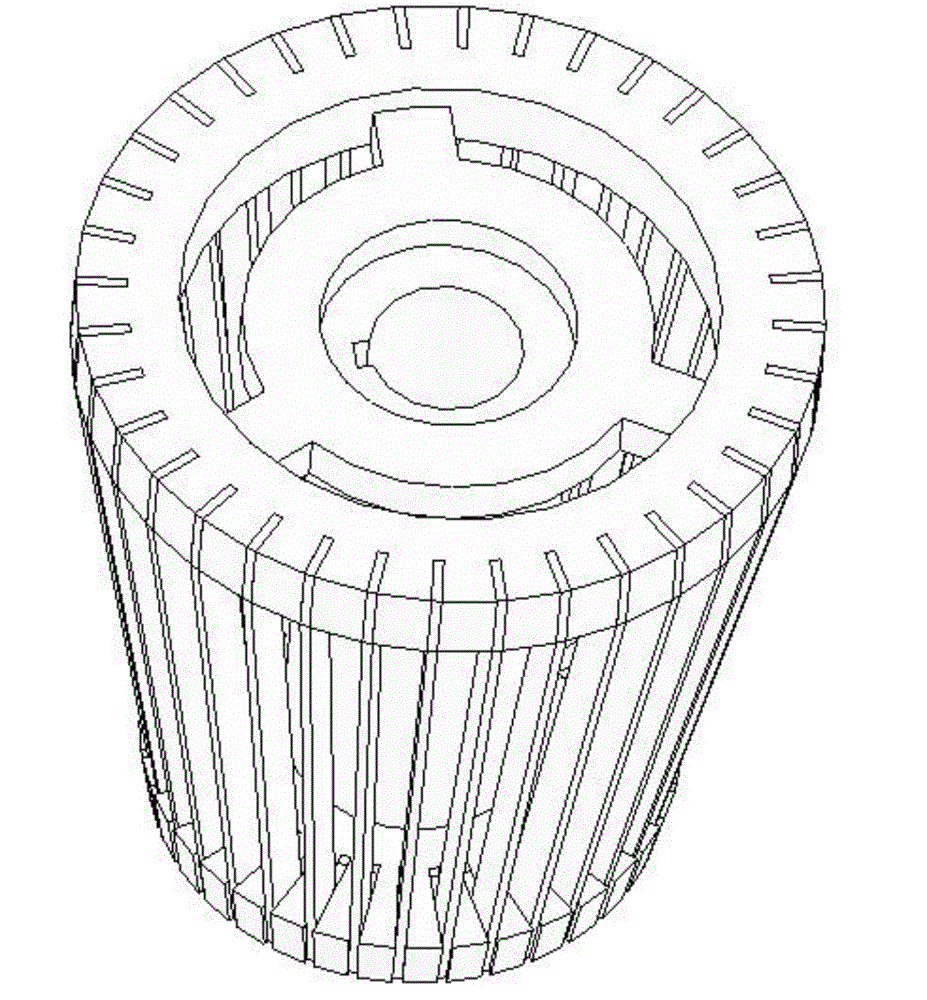

[0028] Through production practice, the size of the ore inlet is 50mm×20mm, the diameter of the cylinder is 250mm, the height is 170mm, the height of the conical cylinder is 595mm, the cone angle is 20°, the diameter of the overflow pipe is 50mm, the diameter of the discharge port is 25mm, and the thickness of the cylinder is 10mm. Open the device of the present invention, open the valve 5 for controlling the amount of slurry, the slurry passes through the slurry inlet pipe 3, and the flow section is circular and extruded into a flow section with a rectangular shape, passing through the reducing tube 9, and entering the cylinder along the cylinder wall 20. Under the action of inertia, the self-flow rotates, and at the same time, under the high-speed agitation of the impeller 22, the slurry accelerates the layering and classification of coarse and fine particles,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com